Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. tray packaging machine If you are interested in our new product tray packaging machine and others, welcome you to contact us.tray packaging machine Exquisite material selection, thick materials, excellent performance, stable operation, safe use, high quality and long service life.

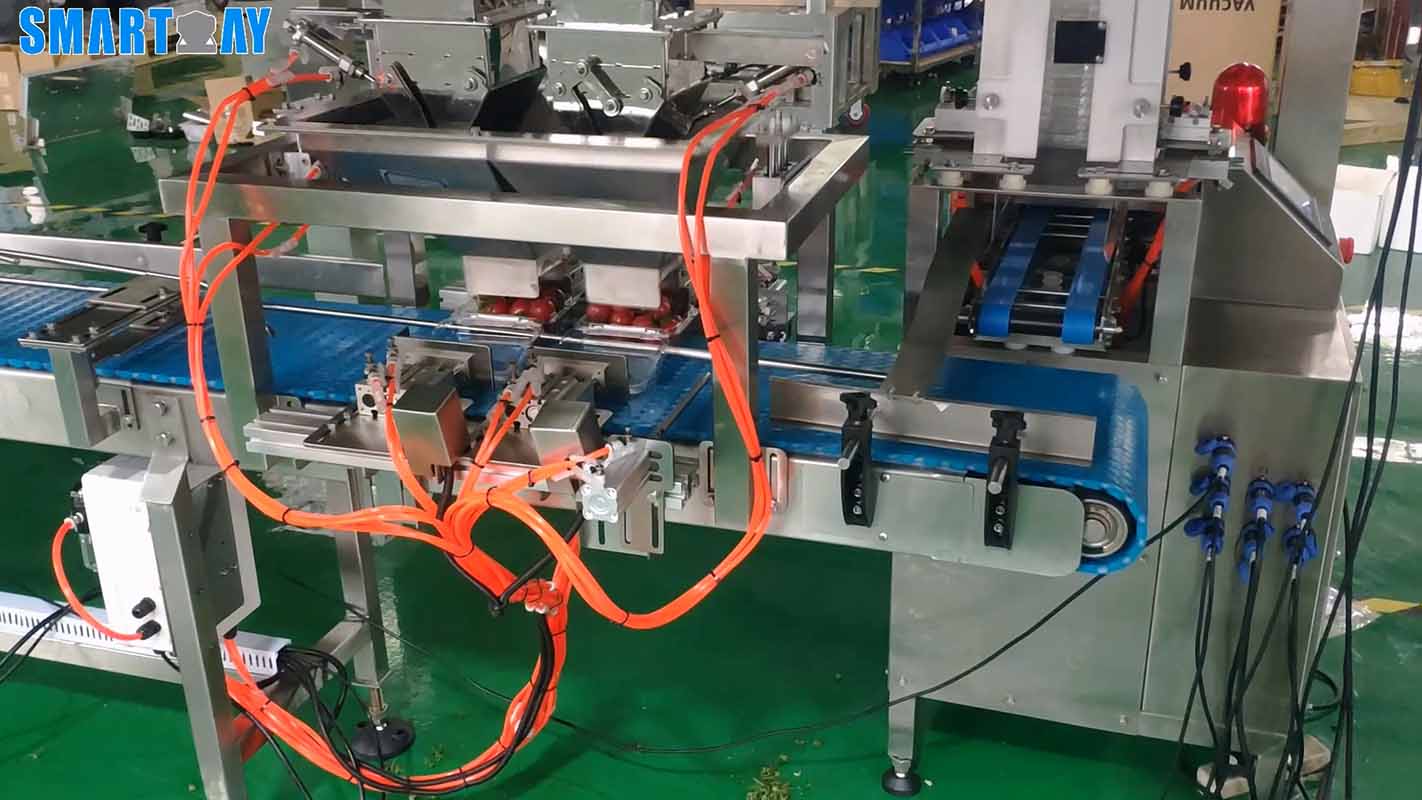

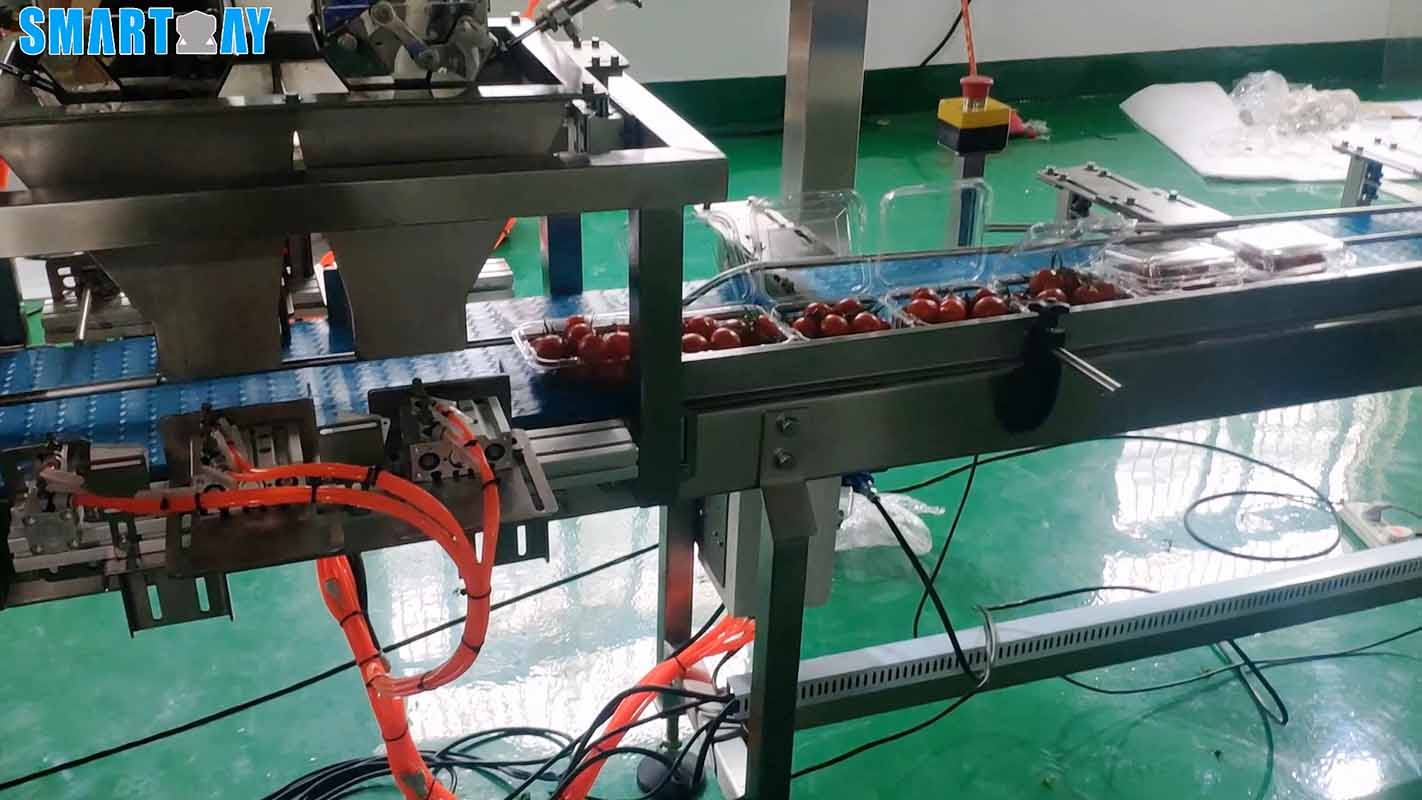

The tray dispensers are the denesting machines that are used to automatically load and accurately pick and place trays. This type of machine is typically used in the food industry, but can also be used in other industries as well. Tray denesting is available in a variety of preformed tray sizes and configurations, and can be customized to meet the specific needs of your business. While it works with multihead weigher or combination weigher, it is applicable for various kind of trays for fish, chicken, vegetable, fruit, and other food projects.

Advantages of Smartweigh's tray denesters

1. The tray feeding belt can load more than 400 trays, reduce the times of feeding tray;

2. Different tray separate way to fit for different material's tray, rotary separate or insert separate type for option;

3. The horizontal conveyor after the filling station can keep the same distance between every tray.

4. The tray denesting machine can equip with your existing conveyor and existing production line.

5. Customize high speeds models: twin tray denester, which placing 2 trays at the same time; we even design the denesting machine to place 4 trays at the same time.

When it works with multihead weighing machines, you can make the feeding, weighing and filling into automatic process for fruits and vegetables, meat, ready meals packing projects.

With this machine, you can experience faster product wrapping than ever before for clamshell trays. The intuitive design is easy to learn and use, providing intuitive operation with a touch-sensitive control console for maximum convenience. Not only does the user interface offer a straightforward approach to customized packaging, but the total operation cycle is also managed efficiently. Operating at speeds up to four times faster than manual operations, these machines process up to 25 wraps per minute providing improved production capacity with full efficiency.

The high speed clamshell packing machine can be used for a wide range of applications including fruit factories, food processing plants and many other industrial sites.

Q1: What industries can use the SW-T1 tray denester?

A1: Primarily food packaging (fresh produce, ready meals, meat, seafood), but also pharmaceutical, cosmetic, and consumer goods requiring tray-based packaging.

Q2: How does it integrate with existing production lines?

A2: Features modular design with adjustable conveyor systems and flexible control integration. Seamlessly connects with multihead weighers and downstream packaging equipment.

Q3: What's the difference between rotary and insert separation methods?

A3: Rotary separation uses rotating mechanisms for rigid plastic trays, while insert separation employs pneumatic systems for flexible or delicate materials.

Q4: What's the actual production speed in real conditions?

A4: 10-40/min for single lane tray, 40-80 trays/min for dual trays.

Q5: Can it handle different tray sizes?

A5: Configured for one size at a time, but quick changeover makes size switching efficient.

Q6: What customization options are available?

A6: Twin denester systems (2 trays simultaneously), quad placement (4 trays), custom sizes beyond standard ranges, and specialized separation mechanisms. Another optional device is empty trays feeding device.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved