Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

After years of solid and rapid development, Smart Weigh has grown into one of the most professional and influential enterprises in China. tray filling and packing line If you are interested in our new product tray filling and packing line and others, welcome you to contact us.tray filling and packing line Our product is crafted entirely from top-notch thickened stainless steel plates, which guarantees a silent operation and a debris-free production process. Not only that, but it's also eco-friendly, providing a green solution that complies with food health regulations. Let us help you elevate your culinary creations with our premium-quality equipment!

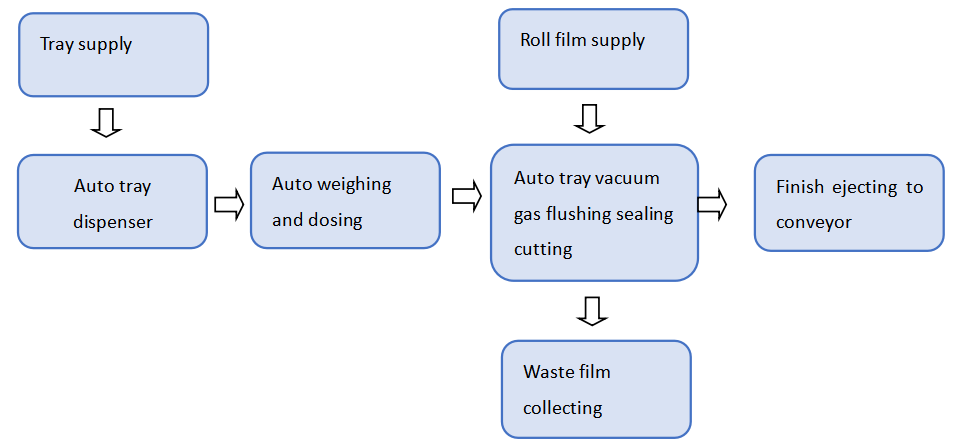

Fully automatic linear tray filling sealing machine can auto loading the empty trays, empty trays detecting, auto quantitative filling product into tray, automatic film pulling and waste collecting, auto tray vacuum gas flushing, sealing and film cutting, auto ejecting the finish product to conveyor. Its capacity 1000-1500trays per hour, suitable for the foods factory production needs.

Whole machine made by stainless steel 304 and anodizing aluminum, ensure it can run on bad food factory environment which has damp, steam, oil, acidity and salt etc. its body can accept the water rinsing clean.

Using high quality imported electrical parts and pneumatic parts which ensure the stable running in long time, reduce the stop and maintenance time.

1.Driven system: servo motor with gearbox for the tray molds stepping running, it can move filled tray very fast but avoid material splash because servo motor can start and stop smoothly, and also high positioning accuracy.

2. Empty tray loading function: it using spiral separating and pressing technology which can avoid the tray damage and deforming, it has vacuum sucker which guide the tray enter into mold accuracy.

3.Empty tray detecting function: it use photoelectric sensor or optical fiber sensor to detect the mold have or haven’t empty tray, it can avoid the mistake filling, sealing and capping if the mold without the trays, reduce the product waste and machine cleaning time.

4. Quantitative filling function: multi-head intelligent combined weighing and filling system is adopted to carry out high-precision weighing and quantitative filling for various shaped solid materials. It is convenient and quick to adjust and has small error in gram weight. Using servo drive material distributor, accurate positioning, small repeat position error, stable operation

5.Vacuum gas flushing system: it makes up by vacuum pump, vacuum valves, gas valves, air release valve, pressure regulating valve, pressure sensor, vacuum chambers etc. it pumping out air and injecting gas to extend the shelf life.

6.Roll film sealing cutting function: The system consists of automatic film drawer, printing film location, waste film collection and thermostat sealing system, sealing system can runs fast and locates at the printed film accurately. Thermostat sealing cutting system uses Omron PID temperature controller and sensor for high-quality heat sealing

7.Discharge system: it makes up by tray lifting and pulling system, ejection conveyor, the packed trays lift and push to conveyor fast and stable.

8.Automation control system: it make up by PLC, Touch screen, servo system, sensor, magnetic valve, relays etc.

9.Pneumatic system: it make up by valve, air filter, meter, pressing sensor, magnetic valve, air cylinders, silencer etc.

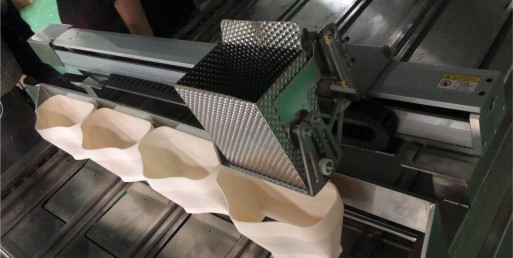

Vacuum gas flushing sealing cutting device

Flow chart of packing

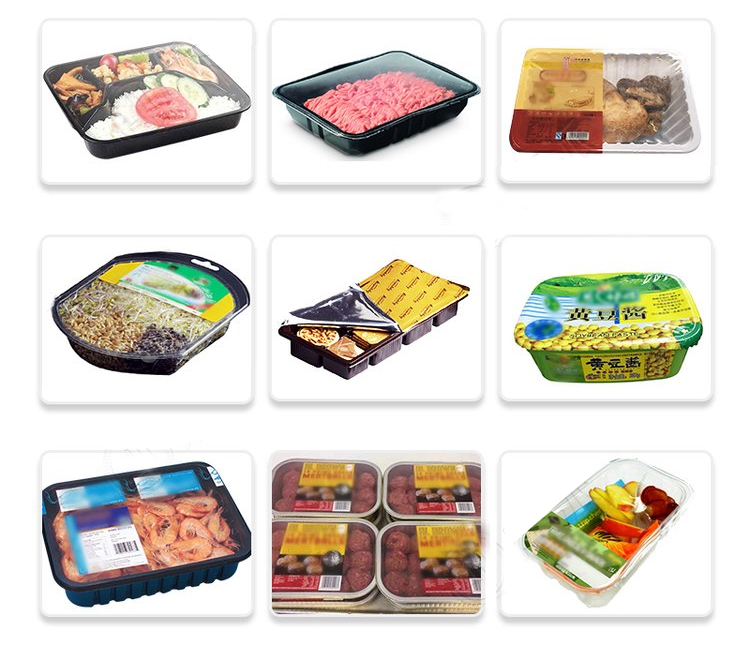

It is widely applicable to trays of various sizes and shapes. The following is part of the packaging effect show

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Inspection Machine and an unforgettable experience of partnering with us.

The buyers of tray filling and packing line come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the tray filling and packing line, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing tray filling and packing line organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved