Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

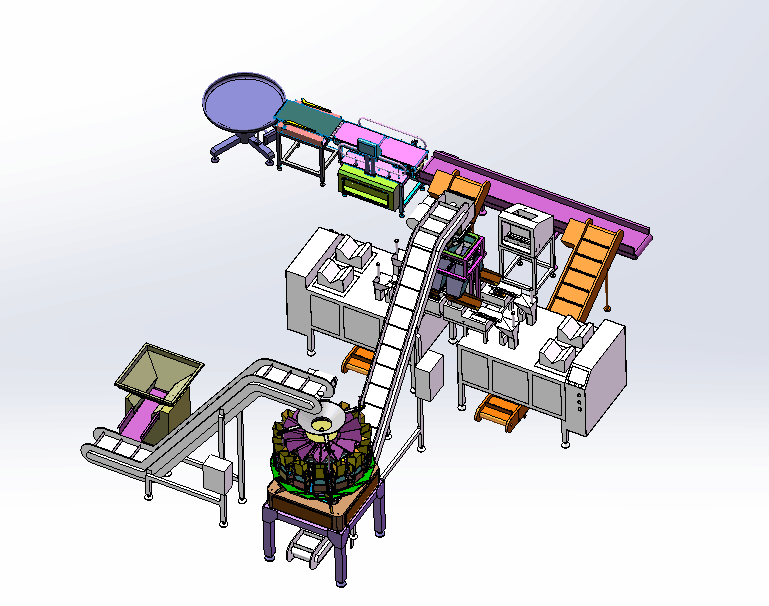

Why choose a secondary lift weighing and packaging system?

After employing our automated secondary lift weighing and packing line, a Polish customer was satisfied. Because the secondary lifting system fixed the plant's space shortage issue and reduces leakage and contamination during food transportation.

Incline conveyor:

l PP grade belt usage can adjust to both high and low temperatures.

l The material can't fall outside while being lifted thanks to the baffle plate.

l The large inclination conveyor's running speed can be flexible adjusted.

l The belt is simple to install, disassemble, and clean.

l Smoothly operating vibrating feeder included.

High precision multi-head weigher for food:

u Made of SUS 304 stainless steel, which has a long service life and is resistant to wear and tear.

u Waterproof to IP65 standards; simple to clean.

u Flexible linear feeder pans construction that is simple to install, disassemble, clean, and maintain.

u Flexible angular adjustment of the discharge chute in accordance with product characteristics.

u Stable operation, fewer errors, and reduced maintenance costs with a modular driving system.

u High weighing accuracy, sensitive response, and central load cell.

u By using the sequential discharge feature, material blockage is prevented.

u Multi-point diverter, timed hopper, and multi-port top cone are optionally available.

Bowl conveyor:

Ø Food grade SUS304 stainless steel is clean and hygienic.

Ø Each bowl has a maximum product capacity of 6L.

Ø About 25 to 30 bowls per minute are transported in the bowl conveyor.

Ø The operation speed of a bowl conveyor can be adaptibly adjusted depending on the properties of the material.

Ø To prevent material from falling outside, sensor identifies position of the material.

In the food business, automatic rotary packaging machine is frequently used to package products like dried meat, beef jerky, meatballs, chicken claws, etc. The entire process of bag picking, coding, opening, filling, vibrating, sealing, shaping, and output can be finished by the stand-up pouch packing machine. A touch screen with a user-friendly interface is included, and it can realize fully automatic packaging.

Optional check weigher and metal detector are available:

Check weigher's capabilities include weighting and rejecting. Three methods can be used to reject overweight or underweight materials: a reject arm, an air blow, or a cylinder pusher. The product is rejected if there are metal contamination found in it, as determined by the metal detector.

The packaging and weighing of fresh foods with stringent hygiene standards, such as meatballs, raw meat, frozen veggies, etc., can be handled using the secondary weighing and packing lifting solution.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425