Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

What are the benefits of a single station machine for packaging pre-made bags?

Nowadays, premade zipper bag is more and more welcome on the market, but many food production owners are not taking the premade bag packing machine because of rotary packing machine price is out of their budget. Smart Weigh pack’s single station premade bag packing machine is perfect to meet their target. Since it is not only save the cost, but also save space, such system is only occupies around 4 square meters, it saves space and is appropriate for start entry production workshops.

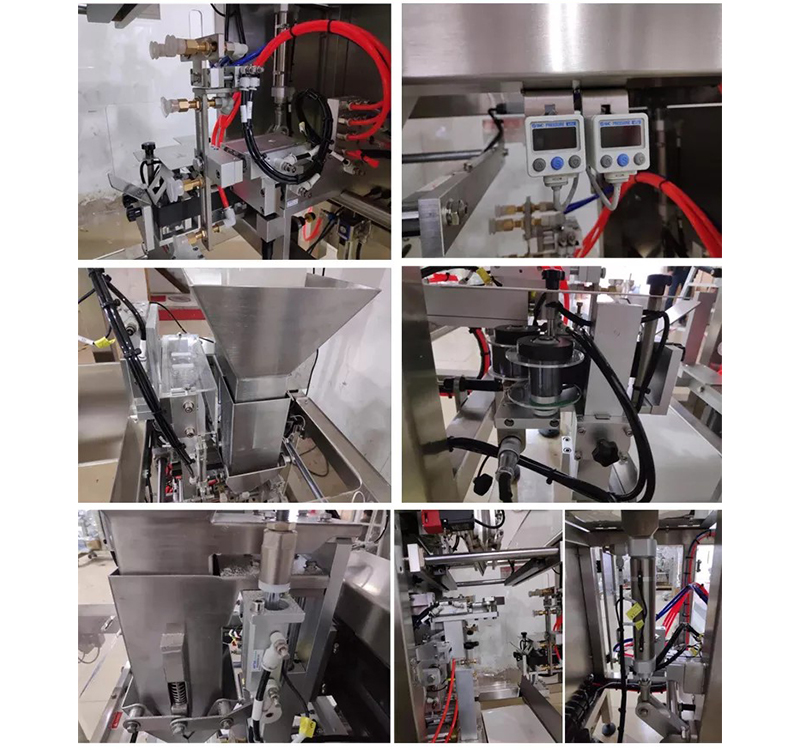

More of the features of the single station premade bag packing system as below:

l The user-friendly touch screen interface clearly displays the important weighing and packing parameters;

l Space saved, cost saved;

l Weighing rang and bag size is wide, there are many models can be chose, bag width from 100-430mm, bag length is from 100-550mm, weighing rang is from 10g-10kg;

l more flexible to do different kinds of bag shape, some of the bag shape can’t run on the rotary packing machine, this machine is widely used on all kinds of premade, like side gusset, quad bag.

l Dual filling and dual station packing machine is available.

Premade bag packaging machine with double stations for more effective packaging and precise metering.

Numerous applications, universal stand-up pouches, zip bags, four-side-seal bags, back-seal bags and various pre-made bags. The seal is beautiful and firm and may satisfy the needs of premium packaging.

It is simple to perform automatic filling of granular and powder materials by using different metering devices based on the material's characteristics.

To complete the entire process of weighing, filling, sealing, finished product output, weight detection, and metal detection, packaging machine can be combined with large inclination lifts/Z type conveyor, multi-head weighers/linear weigher, check weigher/metal detector & checkweigher machine , and output conveyor.

A single station packaging machine for premade bag is frequently used to package granular goods like coffee beans, cereals, candies, powdery goods like flour, washing powder, and spice powder, liquid goods like beverages and soy sauce, and sticky goods like raw meat and noodles. It is also frequently used to package industrial goods like chips and screws as well as pharmaceutical goods like pills and pharmaceuticals.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425