Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

What are the precautions when choosing a multihead weigher?

The multi head weighing machine can weigh three types of materials: block, granular, and powder. Among them, the weighing of block materials can best reflect the superiority of the multi-head scale. It solves the measurement of block materials due to the large weight of a single block. The problem of error coaxial. So what are the precautions for purchasing a multihead weigher? Let's study in detail below:

The precautions when choosing a multihead weigher are as follows:

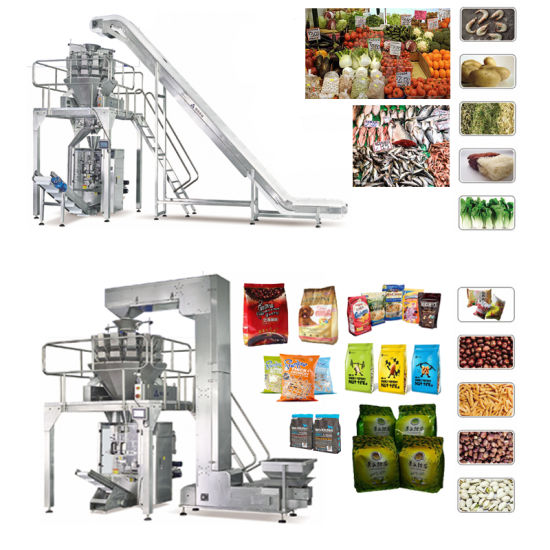

First, the first thing to consider when choosing a multi-head weigher is whether the weighing speed of the multi-head weigher matches the production line. General combination weigher quantitative weighing and packaging system is mainly composed of combination weigher, vertical packaging machine, vibrating feeder, Z-conveyor, support platform and so on. The weighing speed of the multi head weigher mainly depends on the number of weighing hoppers involved. The more weighing hoppers, the faster the weighing speed. If the user has a ready-made packaging machine, then the speed of the multi-head scale should refer to the running speed of the packaging machine when choosing the speed of the multi-head scale, but the speed of the multi-head scale should be slightly higher than the operation of the packaging machine speed.

Second, the weighing range of the product, the size, shape, and viscosity of the product should be considered. If the weighing range is large, the material should be considered to be a combination weigher with more heads such as 14; if the material is viscous, it will be in contact with the material. The feeding hopper and weighing hopper should have anti-sticking properties. Generally, the concave-convex version of the weighing hopper will be selected, otherwise the speed and accuracy of the multi-head weigher will be affected.

The third factor is the weighing accuracy of the multihead weigher. Since the multi-head weigher is a very mature product, the performance of each multi-head weigher is not very different, but because the accuracy of the load cell used in the measurement is different, the weighing accuracy of each multi-head weigher will also have some differences.

The multihead weigher basically does not need to be repaired during use, and only needs to be cleaned daily. In addition, food companies should pay special attention to two points in the process of using multi-head scales: First, keep the continuity, stability, and reasonableness of the supply as much as possible. If the supply fluctuates, make the weighing hopper Too much or too little materials will cause the difficulty or failure of the combination of the multi-head weigher, which will reduce the speed and accuracy of weighing; secondly, the weighing hopper should be as light as possible when disassembling and assembling the weighing hopper. Excessive force will cause the load cell Damaged affects the weighing accuracy and even cannot be used.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425