Uma ubheka ukuqonda umehluko phakathi komshini wokupakisha oyimpuphu kanye ne-granule, usufike endaweni efanele. Uma kushiwo lokho, ukukhetha isethi efanele yemishini kubaluleke kakhulu emabhizinisini. Imishini nje ingenza umehluko phakathi komkhiqizo wekhwalithi enhle kanye nomubi. Ukwengeza, kungase futhi kube nomthelela ekukhiqizeni kokusebenza. Kulesi sihloko, sizoxoxa ngomshini wokupakisha oyimpuphu kanye nomshini wokupakisha we-granule, kanye nomehluko phakathi kwezinhlobo ezimbili zemishini.

Ukupakishwa okuhle komkhiqizo kudinga imishini ekhethekile. Uma kushiwo lokho, umshini wokupakisha oyimpushana uklanyelwe ngokukhethekile ukupakisha izimpushana ezinhle, ezomile, nezinye ezingasindi. Ngomshini onjalo, ungakwazi ukupakisha izimpushana ezitsheni ezahlukene - njengezikhwama namabhodlela. Usebenzisa umshini okhethekile, ungaqinisekisa ukuthi izimpushana zigcwaliswa ngokungaguquki ngokunemba. Ukwengeza, ungavala umkhiqizo ngokuphephile ukuze ugweme noma yikuphi ukungcola nokumosha.

Izimboni eziningi zisebenzisa umshini wokugcwalisa i-powder. Isibonelo - ukudla, imithi, namakhemikhali kuvame ukutholakala kusetshenziswa uhlobo lomshini onjalo. Engxenyeni yokudla, imishini ingapakisha ufulawa, izinongo, ubisi oluyimpushana, kanye nempushana yamaprotheni. Amabhizinisi asemkhakheni wemithi asebenzisa umshini ukupakisha izimpushana zokwelapha kanye nezithasiselo zokudla. Imboni yamakhemikhali, kanti, isebenzisa umshini ukugcwalisa okokuhlanza nomanyolo, phakathi kwezinye izinto.

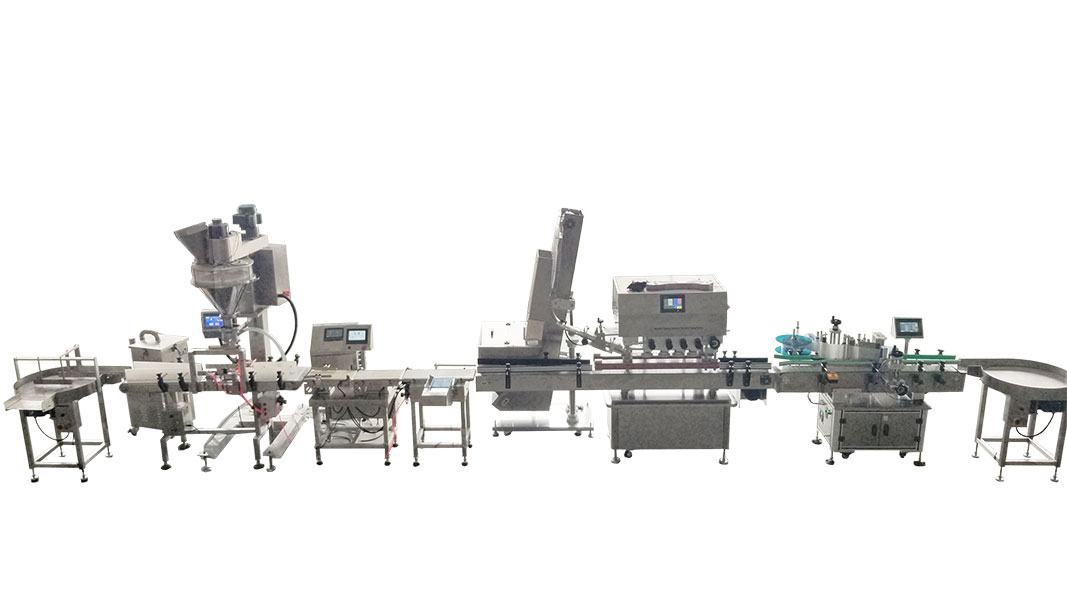

Lo mshini ungapakisha ngokushesha nangokuzenzakalelayo inqwaba yezimpushana ezihlanganisa impushana ye-chili, impushana yekhofi, impushana yobisi, impushana ye-matcha, impushana kabhontshisi wesoya, nofulawa kakolweni. umshini wokugcwalisa isikhwama sempushana onokugcwalisa i-auger kanye ne-screw feeder. Umklamo ovaliwe ungagwema ngempumelelo ukuvuza kwempushana futhi unciphise ukungcoliswa kothuli.

● I-Auger Filler kanye Ne-Screw Feeder: Enhliziyweni yalo mshini kukhona isigcwalisi se-auger, indlela enembayo ekala futhi ikhiphe inani eliqondile lempushana esikhwameni ngasinye. Ibhangqwe ne-screw feeder, iqinisekisa ukugeleza okuzinzile nokungaguquguquki kwempushana ukusuka ku-hopper kuya esiteshini sokugcwalisa, kunciphisa ukungahambisani nokuthuthukisa ukusebenza kahle.

● Idizayini Evaliwe: Esinye sezici ezivelele zalo mshini isakhiwo sawo esivalwe ngokugcwele. Lo mklamo uvimbela ngokuphumelelayo ukuvuza kwe-powder ngesikhathi sokusebenza, ukunciphisa imfucuza yomkhiqizo. Ukwengeza, kunciphisa ngokuphawulekayo ukungcoliswa kothuli, kudala indawo yokusebenza ehlanzekile nephephile kubasebenzisi—inzuzo ebalulekile ezimbonini ezifana nokucubungula ukudla noma imithi lapho inhlanzeko ibaluleke kakhulu.

● Isivinini Esiphezulu Nokuzenzakalela: Umshini uklanyelwe ukupakisha ngokushesha, okwenza kube ukukhetha okuhle kakhulu emigqeni yokukhiqiza yevolumu ephezulu. Uhlelo lwayo oluzenzakalelayo oluphelele lulula inqubo kusukela ekukhipheni impushana kuya ekuvaleni kwesikhwama, kunciphisa isidingo somsebenzi wezandla kanye nokukhulisa ukukhiqiza okuphelele.

Umshini wokupakisha omile wekhofi oyimpushana ulungele ukupakisha izimpushana ezihlukahlukene ezihlanganisa ufulawa, ufulawa wommbila, ikhofi, nompushana wezithelo. Isivinini salo mshini silungiswa ngokuguqulwa kwemvamisa ngobubanzi, futhi isivinini sangempela sincike ohlotsheni lwemikhiqizo nesikhwama.

● I-Screw Conveyor: Lo mshini uhlanganisa i-screw conveyor ethutha kahle impushana isuka ku-hopper yesitoreji iye esiteshini sokugcwalisa. I-conveyor iqinisekisa ukugeleza okulawulwayo nokungaguquguquki, ikwenze kusebenze ngokukhethekile ezimpushaneni ezinhle, ezigelezayo, noma eziyinselele ezingase zivale noma zizinze ngokungalingani.

● Isivinini Esishintshayo Ngokuguqulwa Kwemvamisa: Isivinini sokupakisha salo mshini singenziwa ngendlela oyifisayo kusetshenziswa ubuchwepheshe bokuguqula imvamisa. Lokhu kuvumela ama-opharetha ukuthi alungise isivinini phakathi kwebanga elithile, alihlanganise nezidingo zomugqa wokukhiqiza. Isivinini sangempela esifinyelelwe sincike ezintweni ezifana nohlobo lwempushana epakishwayo (isb, ukuminyana kwayo noma ukugeleza kwayo) kanye nempahla yesikhwama (isb., ipulasitiki, ifilimu elaminethiwe), ehlinzeka ngokuguquguquka kokusebenza.

● Idizayini Emile: Njengomshini wokupakisha ome mpo, yenza izikhwama ngomqulu wefilimu, iwagcwalise ngempushana, bese uwavala ngenqubo eqhubekayo. Lo mklamo ungonga isikhala futhi ulungele izindawo ezinomphumela ophezulu.

Lo mshini wokupakisha uzifanele kangcono izinhlobo ezahlukene zamathini njengepulasitiki, i-tinplate, iphepha, ne-aluminium. Amabhizinisi kuwo wonke ama-verticals embonini - njengokudla nemithi - asebenzisa lo mshini wokupakisha.

● Ukuhlukahluka Ezinhlotsheni Zesitsha: Ikhono lalo mshini lokuthwala izinto ezihlukile zesiqukathi nosayizi liwenza ukwazi ukuzivumelanisa nezimo kakhulu. Kungakhathaliseki ukuthi ibhizinisi lisebenzisa izimbiza zepulasitiki ezincane zezinongo noma amathini amakhulu e-aluminium ukuze uthole izimpushana ezinomsoco, lo mshini ungawuphatha lo msebenzi, unciphise isidingo semishini eminingi ekhethekile.

● Ukugcwalisa Okunembayo: Umshini ufakwe izindlela zokuqinisekisa ukugcwaliswa okunembile kwezimpushana esitsheni ngasinye. Lokhu kunemba kunciphisa ukugcwaliswa ngokweqile noma ukungagcwalisi kancane, kuqinisekisa isisindo somkhiqizo esingaguquki futhi kunciphisa udoti wezinto ezibonakalayo—okucatshangelwa okubalulekile ekusebenzeni okuhambisana nezindleko.

● Izicelo Zemboni Ebanzi: Isetshenziswa kakhulu emikhakheni eyahlukene, okuhlanganisa:

▶ Imboni Yokudla: Eyokupakisha izimpushana njengezinongo, izingxube zokubhaka, izimpushana zamaprotheni, nezingxube zeziphuzo ezisheshayo.

▶ Imboni Yezokwelapha: Ukugcwalisa imithi eyimpuphu, amavithamini, noma izithako zezempilo emabhodleleni noma amathini, lapho ukunemba nokuhlanzeka kubaluleke kakhulu.

Umshini wokupakisha weGranule uklanyelwe ngokukhethekile ukuphatha imikhiqizo enesakhiwo esiyimbudumbudu. Lokhu kungafaka okusanhlamvu okuncane namapellets amakhulu. Ukusetshenziswa kwalo mshini kuqinisekisa ukuthi imikhiqizo ihlanganiswe ngokunemba nokusebenza kahle. Lokhu kuqinisekisa ukuhamba kalula futhi kuthuthukise ikhwalithi.

Amabhizinisi emikhakheni efana nokudla, ezolimo, kanye nezokwakha atholakala kusetshenziswa umshini wokugcwalisa i-granule. Uma kuthiwa, isetshenziselwa ukupakisha ushukela, irayisi, okusanhlamvu nokunye ukudla. Emkhakheni wezolimo, umshini ungasetshenziselwa ukupakisha umanyolo, imbewu, nokudla kwezilwane. Nakuba, embonini yezokwakha, umshini ungapakisha izinto zokwakha ezihlanganisa isihlabathi namatshe.

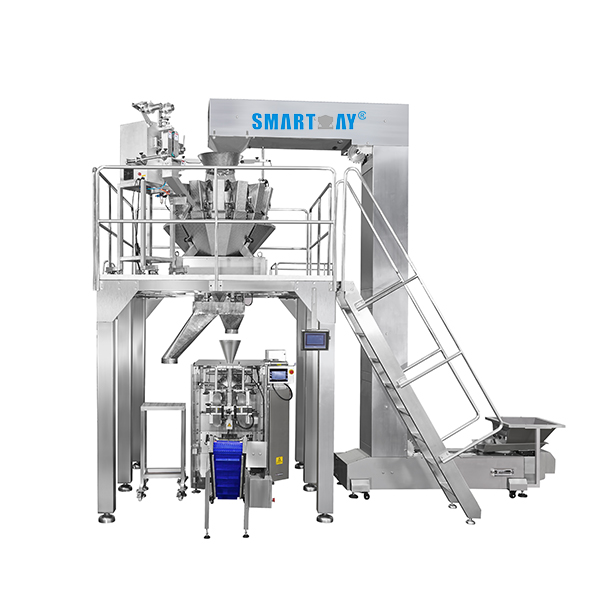

Umshini wokupakisha isikhwama se-weigher multihead wuhlelo olukhethekile olwakhelwe ukugcwalisa nokuvala izikhwama ezakhiwe ngaphambilini ngenani eliqondile lomkhiqizo. Emgogodleni wawo i-multihead weigher, umshini ofakwe amakhanda esisindo amaningi (noma ama-hopper) asebenza ndawonye ukuze alinganise futhi akhiphe imikhiqizo ngokunembile. Nansi indlela esebenza ngayo:

● Inqubo Yokukala: Umkhiqizo usakazwa kuma-weigh hopper amaningana, ngalinye likala ingxenye yesisindo esiphelele. Isofthiwe yomshini ibala inhlanganisela yama-hopper afana kakhulu nesisindo esiqondiwe futhi ikhiphe lelo nani.

● Ukugcwalisa Nokuvala: Umkhiqizo okalwe ngokunembile ube usukhishwa esikhwameni esakhiwe kusengaphambili. Umshini wokupakisha isikhwama ugcwalisa isikhwama bese uyasivala, ngokuvamile usebenzisa ukushisa noma ezinye izindlela zokuvala, ukuze udale iphakethe eliqediwe.

▼ Izinhlelo zokusebenza: Lokhu kusetha kulungile emikhiqizweni edinga ukupakishwa ngenani elithile, njenge:

◇ Ukudla okulula (isb, amashidi, amantongomane)

◇ Ukudla kwezilwane ezifuywayo

◇ Ukudla okuqandisiwe

◇I-Confectionery (isb, amaswidi, ushokoledi)

● Izikhwama zingenziwa ngendlela oyifisayo ngosayizi, ukuma, kanye nempahla (isb., ipulasitiki, ucwecwe).

● Iqinisekisa ukuvumelana futhi inciphisa udoti womkhiqizo ngokunciphisa ukugcwaliswa ngokweqile.

Umshini wokupakisha we-multihead weigher vertical vertical, owaziwa ngokuthi umshini we-vertical form fill seal (VFFS), uthatha indlela ehlukile ngokudala izikhwama ezivela kumqulu oqhubekayo wefilimu. Ihlanganiswe ne-multihead weigher, inikeza inqubo yokupakisha engenamthungo, enesivinini esikhulu. Nansi indlela esebenza ngayo:

● Ukwakhiwa Kwesikhwama: Umshini udonsa umqulu wefilimu eyisicaba, uwulolonge ube ishubhu, bese uvala imiphetho ukuze wenze isikhwama.

● Inqubo Yokukala: Ngokufana nomshini wokupakisha isikhwama, isikali se-multihead sikala umkhiqizo sisebenzisa ama-hopper amaningi futhi sikhiphe inani eliqondile esikhwameni esisanda kwakhiwa.

● Ukugcwalisa Nokuvala: Umkhiqizo uwela esikhwameni, futhi umshini uvala phezulu ngenkathi usikwa kumqulu wefilimu, ugcwalisa iphakheji ekusebenzeni okukodwa okuqhubekayo.

▼ Izinhlelo zokusebenza: Lolu hlelo luhamba phambili ekupakisheni imikhiqizo enhlobonhlobo, okuhlanganisa:

● Izinhlamvana (isb, irayisi, imbewu, ikhofi)

●Izinto ze-hardware ezincane (isb, izikulufu, amantongomane)

● Ukudla okulula neminye imikhiqizo egeleza mahhala

● Ukusebenza ngesivinini esiphezulu kuyenza ifanelekele ukukhiqizwa kwezinga elikhulu.

● Osayizi bezikhwama abahlukahlukene kanye nezitayela zingakhiqizwa ngokulungisa ifilimu nezilungiselelo.

Ungaziphambanisi. Zombili lezi zinhlobo zemishini zenzelwe ukupakisha imikhiqizo ngokunemba nokusebenza kahle. Kodwa-ke, kukhona umehluko phakathi kwemishini yokugcwalisa i-powder ne-granule.

Umshini wokupakisha oyimpushana uklanywe ngokukhethekile ngezici zokuvimbela ukukhiqizwa kothuli nezimpushana ezixegayo. Nakuba, umshini wokupakisha we-granule uklanyelwe ukuphatha imikhiqizo egeleza mahhala.

Emshinini wokupakisha oyimpushana, indlela yokuvala iklanyelwe ukugwema ukubamba impushana ecolekile endaweni yophawu. Ngokuvamile ukuhlanganisa ukukhipha uthuli noma ukuvala umoya ukuze ugweme ukulahleka komkhiqizo.

Ukulawula ukugeleza kwezinhlayiya ezinhle, umshini wokupakisha oyimpushana usebenzisa ama-auger fillers. Ngakolunye uhlangothi, imishini ye-granule isebenzisa amasistimu wokukala ukuze ilinganise futhi ikhiphe imikhiqizo.

Ukutshala imali emishinini yezimboni akuyona nje inqubo ebizayo, kodwa futhi kungaba yinto yesikhathi esisodwa emabhizinisini amaningi. Ngakho-ke, ukwenza utshalomali olufanele kuba bucayi kakhulu. Njengoba kushiwo ukuthi, ukukhetha umshini ofanele, kubalulekile ukuthi ube nolwazi olufanele lwemikhiqizo nezici zayo. Nalu uhlu oluzokusiza ukuthi ukhethe umshini ofanele ngokusekelwe ezidingweni zakho.

◇ 1. Thola ukuthi umkhiqizo wakho ungowempushana ocolekile noma uhlobo lwe-granule bese ukhetha uhlobo oludingekayo.

◇ 2. Uma udinga izinga eliphezulu lokukhiqiza bese ukhetha isistimu ezenzakalelayo enezici ezithuthukile namandla.

◇ 3. Ibhajethi nayo iwukucatshangelwa okubalulekile ngenkathi ukhetha umshini webhizinisi lakho. Ngenkathi ubala isabelomali qiniseka ukuthi ucabangela izici ezihlukene ezifana nokusetshenziswa kwamandla kanye nezindleko zokuyilungisa.

◇ 4. Yenza ukuhlolwa kokuhambisana kwezinto zokupakisha nomshini wokupakisha ngaphambi kokukhetha umshini.

◇ 5. Khetha umhlinzeki womshini onokwethenjelwa, njenge-Smart Weigh, ngoba isevisi yangemuva kokuthengisa nayo iwukucatshangelwa okubalulekile.

Manje njengoba usuwazi ngomshini wokupakisha oyimpuphu kanye nomshini wokupakisha we-granule, ukukhetha okulungile kwebhizinisi lakho kufanele kube lula. Ngezimboni ezahlukene nezinhlobo zemikhiqizo ephethwe yile mishini, ukuthola inketho efanele kuzokusiza ubeke ibhizinisi lakho endleleni efanele. Izinketho zomshini ezihlukene okukhulunywe ngazo ngenhla zonke zihlinzekwa yi-Smart Weigh. Thintana namuhla futhi thina njengomkhiqizi wemishini yokupakisha onolwazi sizokusiza ukhethe umshini ofanele ngokusekelwe ezidingweni zakho kanye nesabelomali.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe