I-Vertical Form Fill Seal Machines iguqula imisebenzi yokupakisha futhi ingagcwalisa amaphakethe angama-200 ngomzuzu. Le mishini iyindlela enhle yokuthuthukisa ukusebenza kahle kwezimboni zokudla, iziphuzo, ezemithi, nezokunakekela abantu. Ukusetha kudinga ukunakwa ngokucophelela ngemininingwane enezinyathelo ezihlukile zokufakwa okufanele.

I-investimenti yokuqala ingaba nkulu. Ukufakwa okufanele kuzokunikeza izinzuzo zesikhathi eside ngokusebenzisa ukusebenza kahle kokukhiqiza kanye nokumosha izinto ezincane. Le mishini eguquguqukayo isebenza ngezinto zokupakisha ezahlukahlukene, ukusuka ku-polyethylene kuya ku-polypropylene. Baphinde banikeze izindlela zokuvala eziningi ezigcina ubuqotho bephakheji.

Lesi sihloko sihlukanisa inqubo yokufaka ibe izinyathelo ezilula. Ngisho nabaqalayo bangakwazi ukubhekana nalo msebenzi oyinkimbinkimbi futhi bathole okuningi emshinini wabo wokuvala ukugcwalisa ifomu eliqondile.

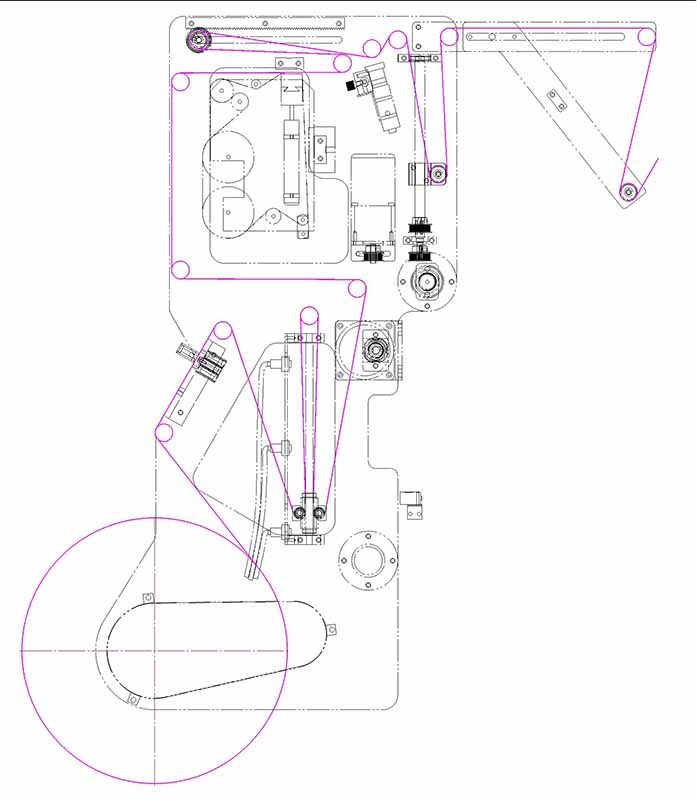

Umshini we-vertical form fill seal (VFFS) uwuhlelo lokupakisha oluzenzakalelayo oludala, lugcwalise, futhi luvale izikhwama kusuka kumqulu oqhubekayo wefilimu. Umshini udala izikhwama zepulasitiki ezinamandla okwenza izimpushana, uketshezi, ama-granules, nezinto eziqinile.

Umshini uqala ngomqulu wefilimu oyisicaba, ngokuvamile ophrintwa kusengaphambili ngamalebula omkhiqizo. Umshini wenza le filimu ube yishubhu, uvale isiphetho, ukale umkhiqizo, uvale phezulu, bese wenza isiphetho sesikhwama esilandelayo. Imishini iyashesha futhi ingakhiqiza izikhwama ezingafika ku-200 ngomzuzu emugqeni we-duplex.

Imishini ye-VFFS ingavala amaphakheji ahlukahlukene, okuhlanganisa ipulasitiki, ifilimu/i-foil eyenziwe ngensimbi nephepha. Amasistimu amaningi aphinde avale amaphakheji ngeshaje ye-nitrogen, enikeza izimpahla impilo ende ngaphandle kwesidingo sezilondolozi zamakhemikhali.

Ikhwalithi yokufaka ithinta ikhwalithi yomkhiqizo womshini nokusebenza kahle kokusebenza. Uhlelo olufakwe kahle lwe-VFFS lusiza amabhizinisi ukuthi ahlangabezane nezidingo zamakhasimende futhi ehlise imfucuza. Impumelelo yomshini incike ekusetheni okunembayo kwezingxenye ezimbalwa ezibalulekile:

● Izinhlelo zokuthutha amafilimu

● Izindlela zokuvala uphawu

● Amayunithi okusabalalisa umkhiqizo

● Amasistimu okulawula izinga lokushisa

Abasebenzi abaqeqeshwe kahle bangasebenzisa imishini ngempumelelo, balungise izinkinga ngokushesha, futhi bagcine ikhwalithi yomkhiqizo engaguquki. Ukusethwa okufanele kuzonikeza izimo zokusebenza ezilungile kuzo zonke izingxenye zomshini futhi kunciphise ukuphuka okungalindelekile okungabiza.

Impumelelo ekufakweni komshini wokugcwalisa ifomu mpo iqala ngokulungiselela okulungile. Siqoqe amathuluzi futhi sabeka izinyathelo zokuphepha ezibalulekile.

Inqubo yokufaka idinga amathuluzi emishini alula kanye nemishini ekhethekile. Kufanele ube nezibuko zokuphepha kanye namagilavu angangeni ekushiseni. Indawo yokusebenza idinga uxhumo olufanele lokuphakelwa kwamandla kanye nezinhlelo zomoya ezicindezelwe ukuze kusebenze umshini kahle.

Ukuphepha kubalulekile kuyo yonke inqubo yokufaka. Ngakho-ke, udinga le mishini yokuzivikela:

● Izindlela zokumisa izimo eziphuthumayo zokuvala umshini ngokushesha

● Izinto zokuzivikela (i-PPE) ezihlanganisa amagilavu amelana nokushisa

● Izibuko zokuvikela ukuvikela amehlo akho

● Vala amadivayisi ukuze uhlukanise amandla

Udinga ukulungisa indawo yokufaka ngokucophelela ukuze uqinisekise ukuthi umshini usebenza ngokuphepha futhi kahle. Isikhala kufanele silingane kokubili umshini futhi sinikeze indawo eyanele yokuwunakekela. Indawo yakho yokusebenza idinga:

● Indawo ehlanzekile engenazo izingozi

● Ubude obanele besistimu yomshini

● Ukuxhunywa kukagesi ngendlela efanele

● Amasistimu wokuphakelwa komoya ocindezelwe

● Amasistimu okulawula izinga lokushisa nokuswakama

Abasebenzi abaqeqeshiwe kuphela okufanele baphathe ukuxhunywa kukagesi futhi banyakazise umshini ukuze bagweme ukulimala noma ukulimala. Indawo yokufaka idinga izimo ezifanele zemvelo ngoba amazinga okushisa aphezulu angathinta indlela umshini osebenza ngayo.

Ukuwina okukhuphukayo ekufakweni komshini wokupakisha we-VFFS kuqala ngokulungiselela indawo efanele kanye nokuhlolwa kwezinsiza. Sihlole indawo yokusebenza ukuze siqinisekise ukubekwa nokusebenza komshini okungcono kakhulu.

Indawo yokufaka idinga ukulandisa ngezidingo zokusebenza zamanje nezesikhathi esizayo. Isithombe esigcwele sesayithi sibheka izidingo zesikhala saphansi, izici ze-ergonomic, namaphethini okugeleza kwempahla. Indawo yokusebenza kufanele ilingane nobukhulu bomzimba bomshini futhi ishiye indawo enobubanzi obungu-450 mm ububanzi nobubanzi obungu-645 mm.

Umshini udinga nje ukuqinisekiswa okuthile kwamandla ukuze usebenze kahle. Amamodeli omshini anemininingwane kagesi:

● Okujwayelekile okungu-220V, isigaba esisodwa, ukunikezwa kwamandla okungu-50 noma okungu-60 Hz

● Uma impushana yangakini ingu-110V noma i-480V, sicela utshele umphakeli wakho ngaphambi kwe-oda.

Ukunikezwa kwamandla okuzinzile phakathi kwebanga likagesi elishiwo kuyisici esibalulekile ekusebenzeni okuphezulu. Uhlelo lokunikezela komoya ludinga ukunakwa okulinganayo, ngemishini esebenza ngokujwayelekile ku-85-120 PSI. Ukunikezwa komoya ohlanzekile nokomile kuzovikela uhlelo lwe-pneumatic futhi kugcine ukumbozwa kwewaranti.

Amaqembu kufanele avikele yonke imigqa yokuphakelwa komoya ngendlela ukugwema izingozi zamapayipi axegayo. Ukunikezwa kokuhlolwa kwesihlungi somoya kusiza ukugcina isistimu ye-pneumatic yomshini wokupakisha isebenza kahle.

Impumelelo ekufakweni komshini we-VFFS iqala ngokunaka imininingwane.

Ithimba kufanele likhiphe amakesi okhuni amahlanu aqukethe ikheshi, isikali sika-elekthronikhi, umshini wokugcwalisa amafomu aqondile, abakaki abasebenzayo, kanye nesidlulisi sokugcina. Ukuhlolwa okuphelele kwazo zonke izingxenye kuzonikeza isithombe esicacile sokuthi akukho lutho olonakele ngesikhathi sokuthunyelwa.

Umhlangano ulandela izinyathelo ezithile eziqala ngokubeka iyunithi enkulu ye-VFFS. Ithebula lokusebenza lihamba phezu komshini futhi lidinga ukuhlelwa nesisindo se-electronic. Kufanele ubeke imbobo yokukhipha ncamashi phakathi nendawo yeshubhu yangaphambili yesikhwama ukuze uthole ukusebenza okungcono kakhulu.

Amaphrothokholi okuphepha adlala indima ebalulekile ekusetheni ugesi. Umshini udinga nje ukuxhumana okuzinzile kwamandla phakathi kwe-208-240 VAC. Ukufakwa okuphephile kwamapayipi omoya nama-valve e-solenoid kuvimbela izimo eziyingozi ekuxhumekeni okuxekethile.

Ama-opharetha aqala ukulayisha ifilimu ngokukhulula umoya kusuka ku-shaft engemuva komshini wokupakisha we-VFFS. I-roll yefilimu yokupakisha ikhuphuka ngokulandelayo, igxile ngokuphelele ku-shaft. Ngokulandela umdwebo osongwayo, ifilimu idlula emshinini futhi iphelela esikhwameni esingaphansi kwesivali esivundlile.

Izinqubo zokuhlola zimelela isigaba sokugcina esibalulekile sokufakwa komshini wokupakisha we-VFFS. Indlela ehlelekile izonikeza ukusebenza okuhle kakhulu futhi ivimbele izinkinga zokusebenza.

Ukuhlolwa okuphelele ngaphandle komkhiqizo kuqinisekisa ukuthi umshini usebenza kanjani. Abasebenzisi kufanele bangene enqoleni yefilimu futhi bahlole zonke izixhumi zezintambo. Iyunithi yophawu olume mpo idinga ukuhlolwa ngokucophelela ukuze kuqinisekiswe ukuma kwayo okuhambisanayo neshubhu elenzayo.

Ukulinganisa isivinini okufanele kudinga ukunakwa okunembile kububanzi besikhwama namapharamitha we-headspace. Umshini usebenza kahle kakhulu ngezilungiselelo ezifanele zefilimu kanye nemingcele yokuvala. Ngaphandle kokungabaza, ugcina ukulawula ukuphatha ifilimu njengento ebalulekile njengoba amafilimu aminyene adinga isikhathi eside sokuhlala ukuze uthole izimpawu ezifanele.

Ukuqinisekiswa kokuqondaniswa kwefilimu kufaka phakathi izindawo zokuhlola ezibalulekile ezimbalwa:

● Ukubeka phakathi nendawo umqulu wefilimu ku-spindle

● Ukuma okuhambisanayo kwama-roller namazinga omdansi

● Ukusethwa kahle kwamabhande okudonsa

● Umsebenzi wokulandelela ifilimu okuzenzakalelayo

Naphezu kwalokho, ama-opharetha kufanele agcine umehluko ofanelekile phakathi kophawu lweso nombala wangemuva ukuze bathole ukubhaliswa okunembile. Inzwa yesithombe-iso idinga ukuma okunembile ukuze ithole amamaki okubhalisa futhi idale ubude bezikhwama obufanayo. Ukuhlola okuvamile kwalawa mapharamitha kusiza ukugcina ukusebenza komshini okuphezulu kakhulu.

Ukufakwa kahle komshini wokupakisha we-VFFS kubalulekile ekusebenzeni kahle. Ngezansi kukhona amaphutha okufaka avamile namathiphu okuwagwema:

Inkinga | Imbangela Engenzeka | Isixazululo |

Umshini awuqali | Amandla awaxhumekile kahle | Hlola umthombo wamandla nezintambo |

Ukungahambi kahle kwefilimu | Ukulutha kwefilimu okungalungile | Lungisa indlela yefilimu nokushuba |

Izikhwama ezingavalwanga kahle | Izilungiselelo zezinga lokushisa azilungile | Lungisa izinga lokushisa le-sealer |

Isikali asikhiphi | Ikhebuli yesignali ayixhunyiwe | Hlola izilungiselelo zezintambo namandla |

Isisindo asinembile | Kudingeka ukulinganisa | Linganisa kabusha i-hopper yesikali |

I-Conveyor ayinyakazi | Ikhebuli yesignali ayixhunyiwe | Hlola izilungiselelo zezintambo namandla |

Ukufaka umshini wokupakisha we-VFFS ngendlela efanele kubalulekile ukuze kuzuzwe ukupakishwa okungaguquki, kwekhwalithi ephezulu. Ngokugwema lawa maphutha ajwayelekile, amabhizinisi angathuthukisa ukusebenza kahle, anciphise isikhathi sokuphumula, futhi andise ubude bomshini wokuphila. Ukugcinwa okuvamile kanye nokuqeqeshwa okufanele komsebenzisi kuqhubeke kuqinisekisa ukusebenza okuhle.

I-Smart Weigh Pack ingumkhiqizi owaziwayo emhlabeni wonke wemishini ye-Vertical Form Fill Sealing (VFFS), ehlinzeka ngezixazululo ezisheshayo, ezinembile nezithembekile zokupakisha. Njengoba sinolwazi olungaphezu kweminyaka eyishumi, singochwepheshe kumasistimu wokukala nokupakisha okuzenzakalelayo ezimbonini ezihlukahlukene ezihlanganisa ukudla, izidakamizwa, nehardware.

Imishini yethu yokugcwalisa amafomu eqondile yenzelwe ukusebenza kahle kusetshenziswa ubuchwepheshe bamuva, iqinisekisa nokubeka uphawu, ukumoshwa kwempahla ephansi, kanye nokusetshenziswa okulula. Singanikeza izixazululo zezidingo ezahlukene zezimpahla ezahlukene: ama-granules, impushana, uketshezi, noma ukudla okuqinile. Ngeqembu lonjiniyela abangu-20+ kanye nekhophi yasenqolobaneni yamazwe ngamazwe, ukufakwa okubushelelezi, ukuqeqeshwa, kanye nokuthengisa ngemva kokuthengisa kuqinisekisiwe.

Ngekhwalithi yethu, inani lemali, kanye nokuzibophezela ekusunguleni izinto ezintsha kumaphakheji ethu, siyisixazululo esingcono kakhulu sezinkampani ezinentshisekelo yokukhulisa ukusebenza kwazo kanye nesivuno. Vumela i-Smart Weigh Pack ibe yisixazululo sakho semishini ye-VFFS enokwethenjelwa, esebenza kahle kakhulu eyenzelwe ngqo imininingwane yakho.

Ukufakwa komshini we-VFFS kubalulekile ukuze kuzuzwe ukusebenza kahle kakhulu kokupakisha kanye nekhwalithi yomkhiqizo. Zonke izinyathelo zibalulekile—kusuka ekuhloleni isayithi kuya ekulinganisweni kokugcina. Lezi zinyathelo zizokunikeza ukusebenza ngempumelelo komshini. Amaphrothokholi alungile okuphepha, amathuluzi, nokuhlanganisa okunembayo kusebenza ndawonye ukwakha ukusebenza okuthembekile. Udinga ukunaka izidingo zamandla, izici zokunikezwa komoya, nokubekwa kwefilimu. Lokhu kuvimbela izinkinga futhi kukhulisa okukhiphayo kwakho.

Ukuhlola nokulinganiswa yizinyathelo zokugcina ezibalulekile ezibonisa ukuthi umshini wakho usebenza kahle kangakanani. Kufanele uhlole ukushuba kwefilimu, izilungiselelo zokuvala, nokulungiswa kwesivinini njalo. Lokhu kunikeza ikhwalithi yephakheji engaguquki futhi kunciphisa izinto ezimoshiwe.

Abanikazi bamabhizinisi abahlakaniphile abadinga usizo lochwepheshe ngokusethwa komshini wabo wokupakisha we-VFFS bangathola ukwesekwa okuphelele ku-smartweighpack.com. Lezi zinyathelo zokufaka nokunakekelwa okufanele kuzosiza ukupakisha ukuthi kufinyelele imigomo yokukhiqiza. Uzogcina izindinganiso zokuphepha ziphezulu futhi wenze lula izinqubo ngesikhathi esisodwa.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe