Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Vertical Form Fill Seal Machines transform packaging operations and can fill 200 pouches per minute. These machines are a great way to boost efficiency in the food, beverage, pharmaceutical, and personal care industries. The setup needs careful attention to detail with distinct steps for proper installation.

The original investment could be substantial. A proper installation will give you long-term benefits through better production efficiency and less material waste. These versatile machines work with different packaging materials, from polyethylene to polypropylene. They also offer multiple sealing methods that maintain package integrity.

This article breaks the installation process into simple steps. Even beginners can tackle this complex task and get the most out of their vertical form fill seal machine.

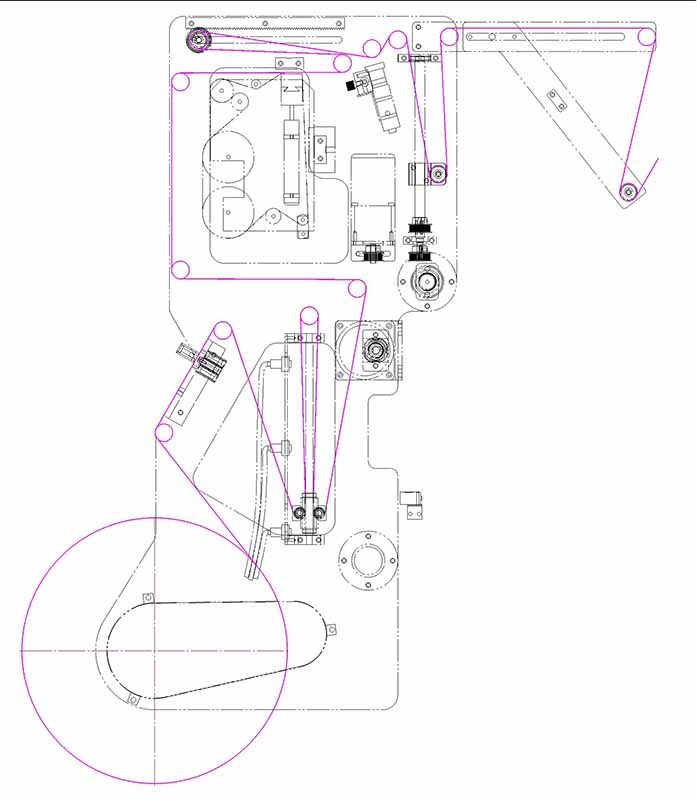

A vertical form fill seal (VFFS) machine is an automated packaging system that creates, fills, and seals bags from a continuous roll of film. The machine creates plastic bags with capacities for powders, liquids, granules, and solids.

The machine starts with a flat film roll, generally preprinted with the product labels. The machine forms this film into a tube, seals the end, weighs the product, seals the top, and forms the next bag's end. The machines are quite fast and can produce up to 200 bags per minute on a duplex line.

VFFS machines can seal various packages, including plastic, metallized film/foil and paper. Many systems also seal packages with a nitrogen charge, giving the goods a longer lifetime without the need for chemical preservatives.

The quality of installation affects the machine's product quality and operational efficiency. A well-installed VFFS system helps businesses meet customer demands and cut down on waste. The machine's success depends on the precise setup of several critical components:

● Film transport systems

● Sealing mechanisms

● Product dispensing units

● Temperature control systems

Well-trained operators can run the machinery effectively, fix problems quickly, and maintain consistent product quality. A proper setup will give optimal working conditions for all machine components and reduce unexpected breakdowns that can get pricey.

Success in vertical form filling machine installation starts with the right preparation. We gathered the tools and put vital safety measures in place.

The installation process needs simple mechanical tools and specialized equipment. You must have safety glasses and heat-resistant gloves. The workspace needs proper power supply connections and compressed air systems to run the machine well.

Safety is vital throughout the installation process. So, you need this protective equipment:

● Emergency stop mechanisms to shut down the machine quickly

● Personal protective equipment (PPE) including heat-resistant gloves

● Safety glasses to protect your eyes

● Lockout devices to isolate power

You need to prepare the installation area carefully to ensure the machine runs safely and well. The space should fit both the machine and give enough room for maintenance. Your workspace needs:

● A clean environment without hazards

● Enough height for machine system

● Proper electrical connections

● Compressed air supply systems

● Temperature and humidity control systems

Only qualified staff should handle electrical connections and move the machine to avoid damage or injury. The installation area needs the right environmental conditions because extreme temperatures can affect how well the machine works.

A soaring win in VFFS packaging machine installation starts with proper site preparation and utility checks. We evaluated the workspace to ensure the best machine placement and operation.

The installation space needs to account for current and future operational requirements. A full picture of the site looks at floor space needs, ergonomic factors, and material flow patterns. The workspace must fit the machine's physical dimensions and leave room for the maximum roll diameter of 450 mm and width of 645 mm.

The machine just needs specific power verification to run properly. Machine models have electrical specs:

● Standard 220V, single phase, 50 or 60 Hz power supply

● If your local powder is 110V or 480V, please tell your supplier before the order

Stable power supply within the specified voltage range is a vital factor for peak performance. The air supply system needs equal attention, with machines typically running at 85-120 PSI. Clean and dry air supply will protect the pneumatic system and maintain warranty coverage.

Teams must secure all air supply lines properly to avoid risks from loose hoses. Supply air filter checks help keep the packaging machine's pneumatic system running smoothly.

Success in VFFS machine installation starts with attention to detail.

The team must unpack five wooden cases that contain the elevator, electronic weigher, vertical form filling machine, worktable brackets, and end conveyor. A complete inspection of all components will give a clear picture that nothing was damaged during shipping.

The assembly follows specific steps that begin with positioning the main VFFS unit. The worktable goes on top of the machine and needs to be arranged with the electronic weigher. You must position the discharge port exactly at the center of the bag's former tube to get the best performance.

Safety protocols play a crucial role in electrical setup. The machine just needs stable power connections between 208-240 VAC. Secure installation of air pipes and solenoid valves prevents dangerous situations from loose connections.

Operators start the film loading by releasing air from the shaft behind the VFFS packaging machine. The packaging film roll mounts next, centered perfectly on the shaft. Following the winding diagram, the film routes through the machine and ends at the bag former beneath the horizontal sealer.

Testing procedures represent the final critical phase of VFFS packing machine installation. A systematic approach will give the best performance and prevent operational problems.

A complete test run without a product verifies how the machine works. Operators must get into the film carriage movement and check all wiring connections. The vertical seal unit needs careful inspection to verify its parallel positioning with the forming tube.

Proper speed calibration needs precise attention to bag width and headspace parameters. The machine works best with correct film tension settings and sealing parameters. Without doubt, you retain control over film handling as a vital factor since thicker films need longer dwell times for proper seals.

Film alignment verification includes several key checkpoints:

● Centering the film roll on the spindle

● Parallel positioning of rollers and dancer levels

● Proper setup of pull belts

● Auto film tracking functionality

In spite of that, operators must keep proper contrast between the eye mark and background color to achieve accurate registration. The photo-eye sensor needs precise positioning to detect registration marks and create consistent bag lengths. Regular checks of these parameters help maintain peak machine performance.

Proper installation of a VFFS packing machine is crucial for optimal performance. Below are common installation mistakes and tips to avoid them:

Issue | Possible Cause | Solution |

The machine does not start | Power not connected properly | Check the power source and wiring |

Film misalignment | Incorrect film threading | Adjust film path and tension |

Bags not sealing properly | Temperature settings incorrect | Adjust sealer temperature |

Weigher not dispensing | The signal cable not connected | Check wiring and power settings |

Weighing not accurate | Calibration needed | Recalibrate the weigher hopper |

Conveyor not moving | The signal cable not connected | Check wiring and power settings |

Installing a VFFS packaging machine correctly is critical for achieving consistent, high-quality packaging. By avoiding these common mistakes, businesses can improve efficiency, reduce downtime, and maximize machine longevity. Regular maintenance and proper operator training further ensure optimal performance.

Smart Weigh Pack is a well-known global manufacturer of Vertical Form Fill Sealing (VFFS) machinery, supplying speedy, precise, and reliable solutions for packaging. With over ten years of experience, we are specialists in automatic weighing and packing systems for various industries including foods, drugs, and hardware.

Our vertical form filling machines are engineered for optimal performance using the latest technology, assuring even sealing, low commodity wastage, and simple usage. We can offer solutions for different requirements for different goods: granules, powder, liquid, or solid foods. With a team of 20+ engineers and extensive international backup, smooth installation, training, and after-sales are guaranteed.

With our quality, value for money, and commitment towards innovation in our packages, we are the best solution for companies interested in maximizing their packaging performance and yield. Let Smart Weigh Pack be your solution for reliable, top-performance VFFS machinery made exactly for your specifications.

VFFS machine installation is crucial to achieving the best packaging efficiency and product quality. Every step matters—from checking the site to final calibration. These steps will give you successful machine operation. The right safety protocols, tools, and precise assembly work together to build reliable performance. You need to pay attention to power needs, air supply specs, and film placement. This prevents problems and maximizes your output.

Testing and calibration are the final critical steps that show how well your machine works. You should check film tension, sealing settings, and speed adjustments regularly. This gives consistent package quality and cuts down on wasted materials.

Smart business owners who need expert help with their VFFS packaging machine setup can find complete support at smartweighpack.com. These installation steps and proper maintenance will help packaging operations hit production targets. You'll keep safety standards high and streamline processes at the same time.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved