Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

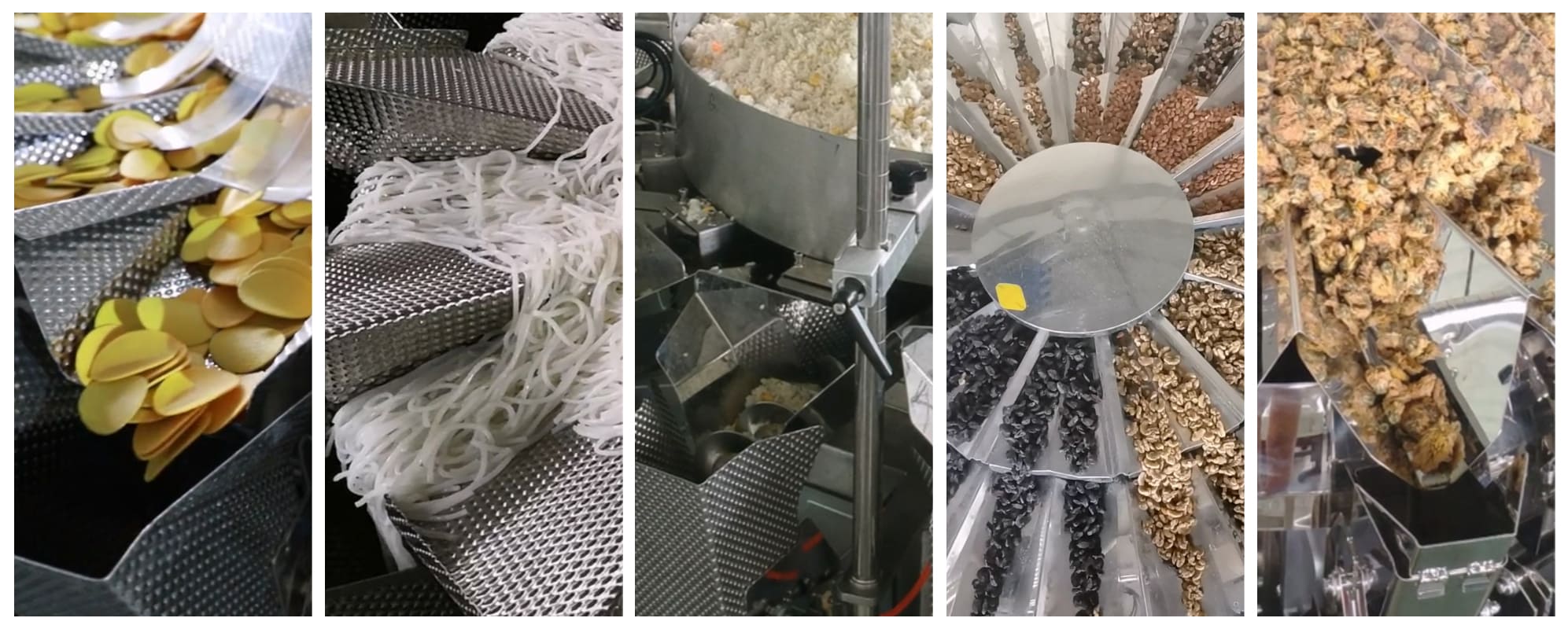

Many processing lines use combination weighers to weigh and sort a range of raw materials to fulfill final product criteria.

Because of its importance, you must choose the proper combination weigher for your operation. This requires considering numerous elements to find a solution for you and your goods.

Finding a suitable combination weigher for your company can boost productivity, quality, and processing speed.

This article discusses combination weigher selections to help you choose.

● Materials

When choosing plant equipment, the first thing to consider is whether it will work with the raw materials or components you will process. You need the right solutions in your line to make production easier and improve quality since different materials have different properties. This includes a combination weigher selection. List any items the weigher will process. Depending on your plant setup, this might be one material or a mix of materials across projects. After identifying your supplies, determine their needs. If you operate with sticky or wet materials like meat, seafood or fried rice, your combination weigher doesn't need hardware characteristics. Finding multihead combination weighers that work with your materials helps speed up production by enabling goods to travel smoothly down your lines. It will improve output quality and avoid equipment errors and material jams from causing downtime.

● Accuracy

Weighing materials requires accuracy. This involves weighing raw materials, ensuring you have enough for processing and minimizing waste, and ensuring your finished product fits packaging and labeling requirements. Accuracy helps you maximize material use and reduce waste and reprocessing by ensuring consistency across all output and lowering expenses. This means any combination weigher you buy must work. Accuracy depends on several things. The machine should be suitable for your goods and have a reliable feeding mechanism and high-frequency load cells. Load cell frequency may also affect material movement since higher frequencies reduce settle time. This will let your weigher sort items precisely without any interaction.

● Productivity

All manufacturers seek to maximize output. Increased productivity reduces expenses, unscheduled downtime, and turnaround time, allowing you to fulfill more demand. Speed and volume, together with trustworthy machinery, affect productivity the most. You want to process as much material as soon as possible without sacrificing accuracy or quality. When buying a combination weigher, compare weighs per minute to see how fast you can weigh things. Think about how much volume the system can handle. Depending on production demands, the weighing range will inform you of this, but the number of weigh heads may enhance the volume handled and sorted.

● Cleaning and maintenance

Your equipment must be easily cleaned and maintained to maximize productivity and use. A speedier cleaning ability lets you flip around lines faster and prevent cross-contamination while reloading your weigher. To avoid buildup in buckets or harm to other items, your equipment must be easy to clean while handling sticky or liquid materials like meat. Compliance also depends on hygiene. Since poorly calibrated or maintained equipment might affect accuracy and production, it must be maintained to avoid downtime, disturbance, and repair expenses. A comprehensive maintenance schedule will help address difficulties quickly, promptly getting the connection back up. Look for features like IP rating (which indicates how waterproof a machine is, affecting how you clean it), bucket shape (larger radius corners are easier to clean), and removable parts when choosing a combination weigher.

Check with your system maker about maintenance plans and fast spare parts. This lets you keep up with maintenance and fix problems quickly and effectively.

● Alignment to processes

Make sure the combination weigher you're buying will work with the tools and procedures you already have in place if you're buying it to fit into your current lines. Discharge points, for instance, might impact how items flow through your line, so the system you choose must enable your products to flow as you want them to and connect with any equipment that could be a part of that line (like conveyor belts). Pre-programmable combination weighers let you establish jobs and enter parameters to ensure the materials are processed according to your standards. This is a crucial function since it enables you to enter and maintain your current needs, such as the policies established with your client or the procedures currently established at your facility. It will automate your workflow and lessen the need for human intervention, enabling consistent outcomes via repeating programs. Discuss the internal protocols the weigher must connect to with the provider of any weighers you are considering purchasing. They must be able to walk you through the system's compatibility and, in some situations, even provide a custom solution for your plant.

● Data analysis

You want to be sure you are receiving the finest performance possible when you invest in any gear. By choosing a system that includes data analysis, you can ensure your linear combination weighers and lines serve their intended function by routinely reviewing performance.

You can maximize your production by using data analysis to ensure that every task is completed accurately and to address any problems before they arise. This implies that you can ensure that your manufacturing line operates to its full potential and produces high-quality final goods to achieve your desired outcomes. It will also help with audits and traceability.

● Energy consumption

Manufacturers are prioritizing environmental effects and green aims by the UK government's net-zero ambitions. With this in mind, whatever equipment you buy must contribute to your company's eco-friendliness, so look for carbon-reducing features. All manufacturing lines require electricity. However, combination weighers with decreased power usage may minimize energy use. This may help you reduce your environmental effects. Your combination weigher's precision will also assist in increasing these credentials by reducing waste, improving productivity, and reducing energy usage by not reprocessing lines or throwing away materials.

Conclusion

Like any other piece of equipment on your manufacturing line, you must ensure your combination weigher gives you excellent performance and outcomes.

Searching about and contrasting models according to accuracy, compatibility, productivity, total cost of ownership, and other aspects that could be important to your plant can help you choose the finest option. When you finally locate the suitable multihead combination weigher, all you need to do is incorporate it into your production lines, and you'll see a return on investment in the form of increased output and higher-quality products.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved