Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Vertical machines are gaining more ground among recent users and consumers. The machine guarantees maximum efficiency and flexibility, which is the reason it is used to pack products comprising of powder, granules, liquid, solid and much more. Let’s try to find out why manufacturers choose vertical form fill and seal machines.

A vertical packaging machine is a type of automated equipment designed to package products into bags or pouches. Vertical packing machines in contrast to horizontal packing machines work upward in the sense that vertical machines make bags from a roll of films and fill them with the product before sealing at the opening of the bag. This technique is particularly suitable for filling operations since such products are usually filled accurately within a day. This is the basic characteristics of VFFS packaging machines:

✔Forming Mechanism: Vertical machines create bags from flat film rolls, using heat and pressure to seal the edges. This process allows for the efficient production of various bag sizes and styles.

✔Filling System: Depending on the product manufactured, vertical packing machines can use- screw fillers, volumetric fillers or liquid pumping systems among other mechanisms. This feature enables them to be used in different ways.

✔Sealing Techniques: These machines commonly employ heat sealing with cooling to maintain the seal of the bags and protect the contents within as a concern for their freshness.

✔User-Friendly Interface: Most vertical form fill seal machines come with easy controls including touch panels that allow easy programming and performance observation by the operator.

Vertical packing machines are essential for various industries, from food to pharmaceuticals. It offers efficient and accurate packaging solutions. Smart Weigh provides a range of vertical form fill seal (VFFS) machines. These machines are designed to meet diverse packaging needs. Let’s explore some of the different types of VFFS packaging machines that Smart Weigh offers.

Industry leaders consider the SW-P420 to be ideal for filling pillow or gusset pouches. This makes it ideal for industries that require the use of fast and accurate bagging. Handles laminated films, single-layer laminates, and even MONO-PE recyclable materials which is good for environmental packaging. It has a branded PLC system for improved speed and accuracy.

It is suitable for products that require only a three-fourths side seal and is usually applied in both pharmaceutical and cosmetics industries. It makes sure that every sachet which has a product inside is properly sealed to preserve that said product. Gas flushing and/or Watertight cabinets allow it to be multipurpose for many packaging applications.

The SW-P250 will be ideal for packing tea and regrettably small granules. It produces infold triangle bags that can be used in the retail market which allows for packing of the contents inside or outside without compromising their freshness.

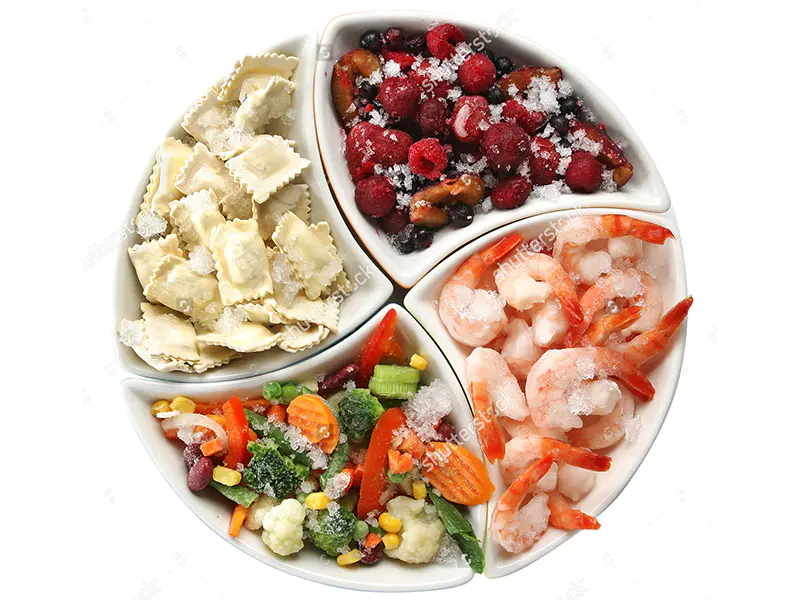

For more heavy packing operations the SW-P460 delivers quad-sealed bags. Ideal for large bulky products such as frozen foods and other items that are required in bulk. Its production ability, which is also low on product spoilage, is designed for mass production.

This machine is built for industries requiring rapid packaging speeds, such as snacks and frozen foods. With continuous motion, it maximizes production efficiency, making it a top choice for companies needing to meet large-scale demands quickly.

The twin formers system is ideal for industries needing dual packaging lines. It can produce pillow bags while connecting with a twin discharge 20-head multihead weigher, ensuring fast and accurate filling for products like chips, snacks, or cereals.

For companies needing precise weighing, the SW-M10P42 offers a compact, high-performance solution. It is ideal for packaging small to medium granules, such as candies, nuts, or snacks. The machine ensures that each bag contains the exact weight every time.

Vertical packaging machines are versatile and can be utilized across various industries, enhancing efficiency and ensuring product integrity. Here are some key applications:

The use of vertical packaging machines in the pharmaceutical is prominent as it helps to ensure the cleanliness and integrity of the product. Applications include:

▶Snacks and Confectionery: These machines are ideal for packaging chips, nuts, granola bars, and candy. Their ability to form airtight seals helps maintain freshness and extend shelf life.

▶Dry Foods: Items like pasta, rice, and flour are commonly packaged using vertical machines. The machines provide accurate portion control and efficient packing speeds. It can be very useful for high-demand products.

Even the pharmaceutical industry relies on vertical form fill seal machines. Because it has the ability to maintain hygiene and product integrity. Applications include:

●Powdered Medications: VFFS machines can package powdered drugs in sachets or pouches. It ensures accurate dosing and prevents contamination.

●Tablets and Capsules: These machines can package tablets in blister packs or bags.

●Liquid Medications: Similar to their use in the food sector, VFFS machines efficiently package liquid medicines. It ensured sterile conditions throughout the process.

■Dry Pet Food: Bags are available for kibble and dry and other dry pet food. The packaging protects the contents from spoilage and infection.

■Wet Pet Food: Vertical fillers machine pack a complete container of canned or pouch pet food quickly and efficiently with vents longitudinally placed in the works.

Apart from food and pharmaceutical applications, vertical pouch packing machines are also used in some industrial areas:

▲Powders and Granules: It is possible to package dry powders like chemicals or fertilizers into a specific container, in a manner to achieve precision in measurement without waste.

▲Hardware and Parts: Hardware components such as bit parts can be put into a bag for easy packaging and handling.

The VFFS packer machines are created in such a way that they do high-speed operations which will increase productivity a lot. Production of bags can also be done at great speed, such that high demand by manufacturers can be met with little or no heating. There is less packaging process done manually as the packaging is done through machine thus averting seek for more labor.

The very first advantage of using a vertical pouch packing machine is that it is very versatile. They come in a variety of forms, including powder, granulate, liquid, and solid. With such flexibility, production processes can easily change from one product to another in response to the demands of the market without much change in the configuration.

Like horizontal packing machines, vertical packing machines do occupy a lesser space. Thus these are recommended to the industries that have minimum workspace. These vertical machines can be attached and fixed on a production line without wasting any floor space.

VFFS machines provide consistent sealing and filling, ensuring product integrity and reducing the risk of contamination. The airtight seals created by these machines help maintain freshness and prolong shelf life, which is especially crucial for food products.

Many vertical packaging machines offer customizable features, allowing manufacturers to tailor the equipment to their specific needs. This includes adjustable bag sizes, different sealing methods, and integrated labeling systems. Customization options enhance branding opportunities and ensure that products meet market requirements.

Modern VFFS machines come equipped with intuitive controls and user-friendly interfaces, making operations straightforward. Training new staff is simplified, and operators can quickly adjust settings to optimize performance for various products.

Investing in a VFFS machine can yield significant cost savings over time. The reduction in labor costs, improved efficiency, and minimized waste contribute to a favorable return on investment. Additionally, the ability to produce high-quality, eye-catching packaging can enhance product appeal and drive sales.

Purchasing a VFFS machine will definitely lead one to long-term savings. This is due to the decrease in working expenses, the faster processes lessened management costs, ensuring a good return on equity. Additionally, the production of attractive packing of goods reasons increases the sale of products.

Vertical form fill and seal (VFFS) machines have become the all-time choice of manufacturers as they are versatile, effective and economical. The machines' performance makes it easy to work with diverse products, possesses various customization features as well as a simple interface which makes it essential in the food industrial sectors. With their high-speed, accurate, and versatile machines, businesses can enhance production efficiency and ensure product quality using vertical machines from Smart Weigh .

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved