Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

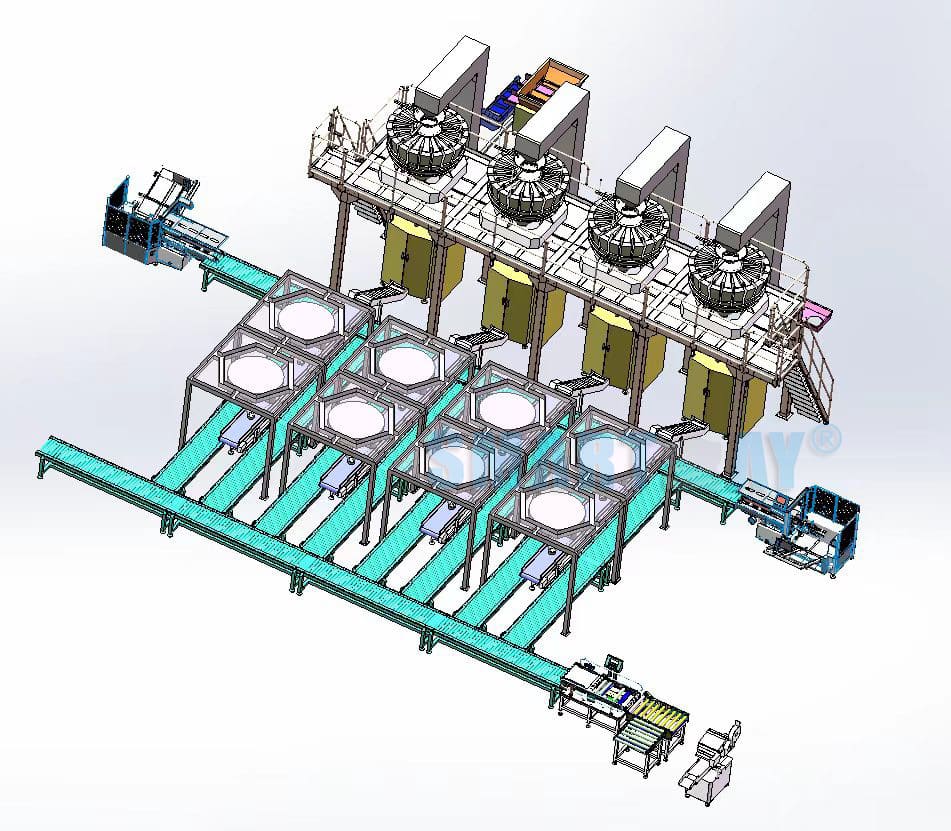

In the rapidly evolving snack packaging industry, where consumer preferences and market trends can change in the blink of an eye, Smart Weigh is constantly seeking ways to streamline their production lines and enhance packaging efficiency. Our snack food packaging machine system represents a significant leap forward in addressing these needs, combining high performance with an automated process that ensures both speed and precision from start to finish.

At the heart of this revolutionary packaging system is the multihead weigher with vertical packing machine, capable of producing 100-110 packs per minute. This remarkable speed does not come at the cost of accuracy or quality, as each pack is meticulously crafted to meet the stringent standards of the snack industry.

Following closely in efficiency, the case erector with Parallel Robot processes up to 25 cartons per minute, setting the stage for a seamless packaging process that keeps pace with the vertical form fill seal machine's output.

The automated process of this snack packaging machine system is where technology truly shines, offering a glimpse into the future of snack manufacturing. Unmanned packaging has become a reality.

The journey begins with auto feeding, where snacks are automatically transported to the weighing station - multihead weigher, ensuring each pack contains the exact amount of product. From there, the system proceeds to filling, where the snacks are carefully deposited into their respective packs.

The innovation continues with the creation of pillow bags by vertical packaging machine, a popular choice for snack packaging due to their convenience and aesthetic appeal. These bags are then prepared for their final journey as a carton opening machine transforms flat cardboard into ready-to-fill cartons.

In a display of technological prowess, a parallel robot efficiently picks the finished bags and places them into the cartons. This robotic intervention not only enhances precision but also significantly reduces the likelihood of human error and contamination, a crucial consideration in food packaging.

The final steps in this automated odyssey involve closing and taping the cartons, ensuring they are securely sealed and ready for transport. However, the system's commitment to quality does not end here. A final check of the net weight guarantees that each package meets the promised content weight, reaffirming the manufacturer's commitment to consumer satisfaction.

Tailored Solutions for Diverse Needs

Smart Weigh recognizes that one size does not fit all in the snack industry. With a diverse range of products and packaging needs, manufacturers require solutions that can be customized to their specific requirements.

We excel in offering flexible packaging solutions that can be adjusted for different sizes, weights, and types of snack products like potato chips, tortilla, nuts, trial mix, beef jerky and dried fruits. This adaptability ensures that manufacturers can not only meet current market demands but also easily adjust to future trends and consumer preferences. Besides, we will also consider your factory floor space and height, your exisiting machine while designing the solutions.

Seamless Integration of Advanced Automation

Smart Weigh's automated packaging process is akin to a well-orchestrated symphony, where each movement is precise and every step is in harmony. From auto-feeding to the final check of net weight, Smart Weigh ensures a seamless flow that optimizes efficiency and maintains product integrity. This integration is key to handling the delicate balance of speed and precision, offering a streamlined operation that minimizes downtime and maximizes output.

Smart Weigh - The Smart Choice for Snack Packaging

In conclusion, the decision to choose Smart Weigh for your snack packaging needs is a strategic one, grounded in a commitment to efficiency, innovation, and adaptability. By embracing Smart Weigh’s advanced systems, manufacturers can elevate their snack packaging process, ensuring that they not only meet the current demands of the market but are also poised for future success. With Smart Weigh, the future of snack packaging is not just efficient and sustainable; it's smart.

|  |

The Bottom Line

The snack food packaging machine system of Smart Weigh’s above represents more than just a technological advancement; it also is a testament to the industry's ongoing commitment to efficiency, quality, and innovation. By integrating high-performance snack packing machines with an automated process that covers every aspect of packaging, snack manufacturers can now meet the growing demand for their products more effectively and efficiently than ever before. If you are looking for chips packing machine manufacturer, you can choose to cooperate with us, welcome to contact us!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved