Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Welcome to the exciting international of chips packaging! Today, we're exploring the adventure from a single chips packaging system to a comprehensive chips packaging line. This evolution marks a substantial jump in how snack foods reach your favorite stores, ensuring they are fresh, perform well, and are nice.

Imagine a system that transforms bulk chips into well-packaged snacks equipped for the shelf. That's your chips packaging machine. It's now not just a bit of a packaging machine; it's the first step in the journey of a chip from the factory to your taste buds. This gadget precisely wraps chips in airtight packaging, ensuring they live clean and crispy till they reach you. But it's greater than just wrapping. It's approximately maintaining the great flavor of the chips, making sure they're just as the maker meant.

Potato chips Packing Machine typically refers to a packaging system used in the packaging process, which may include components like:

✔Feed conveyor: Transports the chips to the packaging machine.

✔Multihead weigher: Accurately measures the chips to ensure consistent portion size.

✔Vertical packing machine: Forms, fills, and seals the bags containing the chips.

✔Output conveyor: Moves the packaged chips to the next stage of the process.

This setup represents a mature, integrated system designed for efficiency and accuracy in packaging chips.

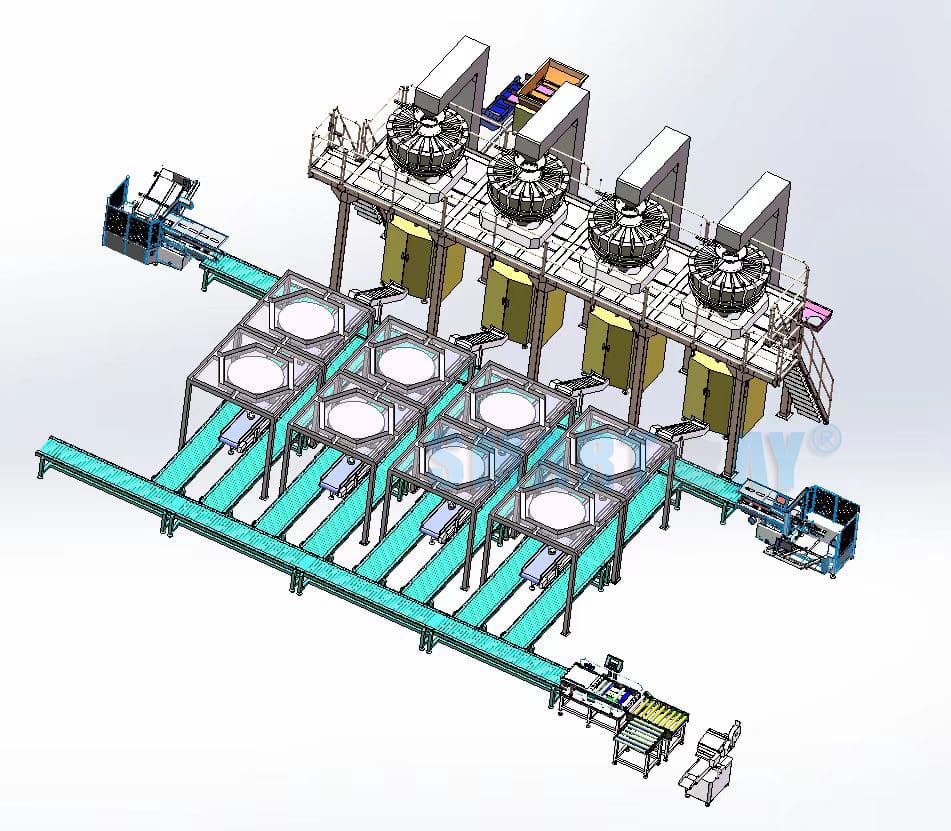

Chips Packing Line, on the other hand, encompasses a broader scope, including the chips packaging machine as well as additional automation equipment for a complete end-to-end packaging solution. This might include:

✔Cartoning system: Automatically places the bags of chips into boxes for shipping.

✔Palletizing system: Arranges the boxed chips onto pallets for distribution and transport.

Smart Weigh provide these comprehensive packaging solutions, emphasizing a one-stop approach that covers everything from the initial packaging of the chips to preparing them for shipping and sale. This not only streamlines the packaging process but also optimizes efficiency and productivity in the production line.

Now, take that single device and multiply its competencies. Envision an entire orchestra in which every musician's contribution leads to a stunning symphony. Similarly, a chips packaging line harmonizes numerous processes to create an unbroken waft from one degree to the subsequent. It's a soar from personal attempt to collective performance. This line isn't always just about packing; it is a meticulously designed system where feeding, weighing, filling, packing, labeling, cartoning, and palletizing all occur in a coordinated way. In China, we are proud to be a few of the chosen few who have mastered this complete approach, ensuring that every packet of chips is a testament to superior packaging generation.

▪Feeding: The adventure starts with the feeding method, in which chips are lightly guided into the system, ensuring they're handled with care from the beginning.

▪Weighing: Precision is prime, and every batch of chips is weighed to guarantee that purchasers get exactly what they anticipate. This step guarantees consistency and pride in every packet.

▪Filling: Here's where the magic happens. Chips are carefully located in their packaging, like treasured treasures being saved for safekeeping. This procedure is important for keeping the chips' integrity and freshness.

▪Packing: Next, the pillow bag packaging is formed and sealed, growing a barrier that locks in freshness and keeps out moisture and air, the enemies of crunchiness.

▪Labeling: Every packet gets its personal label, a mark of identity that tells you everything you need to know about what is internal. It's like giving each packet a unique story to tell.

▪Cartoning: This part includes the case erector and robot. Once categorized, the packets are placed into cartons which formed by case erector, preparing them for adventure beyond the factory. This step prepares the business enterprise and its performance, ensuring products are easily transported and stored.

▪Palletizing: The very last step is palletizing, wherein bins are stacked on pallets and prepared for distribution around the globe. It's a second of the end result because the chips are actually set to embark on their very last journey to stores and eventually to consumers.

To reach production goals in medium- and high-volume production, a steady daily output must be maintained. It's crucial to maintain this capacity, and it's vital to understand that doing so can come with additional costs, especially in the chip packaging process.

▷Precision at Every Step

Imagine the system of packaging chips as an art shape with every detail covered. The chip packaging line system is engineered to handle chips with the utmost care, ensuring that each chip is dealt with as a delicate piece. This precision extends from when the chips are fed into the line through the weighing, filling, and sealing approaches. The purpose is to maintain the integrity of every chip, avoiding breakage and ensuring a regular quantity in every packet.

▷Efficiency That Benefits Everyone

Efficiency is fundamental in any manufacturing, and the chips packing line system is a celebrity performer in this area. It appreciably reduces the time taken to package chips compared to guide strategies. But here's the kicker: this performance would not simply gain the manufacturer. It translates to fee savings, more energizing merchandise on keep shelves, and, in the long run, a higher fee proposition for you, the patron.

▷Quality You Can Taste

Quality isn't always only a buzzword; it is the spine of the chip packaging line. From ensuring that each packet has simply the proper quantity of chips to maintaining optimal freshness, the packaging line is designed to fulfill the best standards. This relentless awareness of the exceptional methods that while you open a bag of chips, you are greeted with identical exquisite taste and crunchiness each time, as though they had been just made.

▷The Human Touch in Automation

In a generation in which automation is ubiquitous, the fee of human contact cannot be overstated. Here's how it performs a critical position in the chips bags packaging line:

▷Design With Humanity in Mind

The potato chips packaging line is not only a series of machines but a device designed with human needs and sensibilities in mind. Engineers and designers have poured their expertise into creating a device that respects the nuances of snack manufacturing, ensuring that the machines beautify the product instead of detracting from its greatness.

▷Craftsmanship and Quality

Behind every chips packing line is a crew of experts who ensure that the machinery operates seamlessly. These experts bring their craftsmanship to the forefront, satisfactory-tuning the machines to maintain the high standards expected by customers. This human oversight is the secret factor that ensures every packet of chips meets your expectations for first-class.

▷The Balance of Man and Machine

While the chips bags packaging line takes care of the repetitive, exertions-intensive responsibilities, the human personnel imbues the system with a feel of care, first-class, and attention to detail. This collaboration between guy and machine sets a potato chips packaging line apart, ensuring that the chips you adore are not just products of generation but also human determination and passion.

In snack manufacturing, mainly chip packaging, the horizon usually increases thanks to technological improvements. These innovations are not just enhancing how we package our favorite snacks; they're redefining enterprise standards and pushing the limits of performance, quality, and sustainability. Let's delve into how these technological breakthroughs are remodeling chip packaging strains and what it means for producers and customers alike.

✔ Elevating Efficiency with Cutting-Edge Technology

Creating advanced automation and robotics in chip packaging traces is a recreation-changer for efficiency. Modern packaging strains can manner lots of chip applications per hour, some distance exceeding what becomes viable with older equipment or manual approaches. These improvements imply quicker turnaround instances, enabling manufacturers to fulfill increasing purchaser needs without compromising first-rate.

✔ Smart Systems and IoT Integration

Imagine a packaging line that self-optimizes based totally on real-time data. That's the power of Internet of Things (IoT) integration. Smart sensors and linked gadgets constantly gather and analyze records, permitting the packaging line to modify its operations for gold-standard performance. This degree of intelligence in machinery no longer most effectively boosts performance; however, it additionally minimizes downtime and waste.

✔ Enhancing Quality Through Precision and Consistency

Technological advancements bring a new degree of precision to the packaging manner. State-of-the-art equipment ensures that every bag of chips is packed with the precise amount, sealed perfectly to preserve freshness, and checked for nice via computerized vision structures. This consistent way that consumers can anticipate the same splendid experience with every purchase reinforces logo loyalty and acceptance as true.

✔ Advanced Quality Control Measures

With the mixing of superior sensors and system learning algorithms, chip packaging traces can now detect even the slightest deviations in quality. Whether it is figuring out a seal that's not quite ideal or ensuring that every package has the right weight, these systems ensure that only the finest merchandise that meets stringent high-quality criteria reaches the customer.

✔ Pioneering Sustainability in Packaging

As environmental issues become increasingly paramount, the snack industry is under strain to reduce its ecological footprint. Technological innovations in packaging strains are answering this name by optimizing fabric use, decreasing waste, or even allowing the usage of extra sustainable packaging substances.

✔ Waste Reduction and Material Optimization

Modern chip packaging strains are designed to minimize waste at every turn. From the usage of precise amounts of packaging material to decreasing product wastage at some stage in the packaging procedure, these advancements contribute appreciably to sustainability efforts. Moreover, the capability to seamlessly integrate biodegradable or recyclable packaging substances into the manufacturing line is a massive jump forward in green production.

The jump from a chip packaging device to a potato chips packaging line is more than just a technological development. It's about setting new standards within the snack industry, ensuring that each packet of chips you enjoy is fabricated with precision, care, and innovation. So next time you savour a chip, take into account the splendid adventure it's been on, way to the marvel of a chip packaging line.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved