Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The global popcorn market is showing a robust growth trajectory. As of 2024, the market size is estimated at USD 8.80 billion and is projected to reach USD 14.89 billion by 2029, growing at a CAGR of 11.10% during this period. This growth is driven by various factors, including the nutritional benefits of popcorn and the emergence of gourmet and flavored popcorn.

Data source: Popcorn Market - Growth, Industry Forecast & Analysis.

As the popcorn market continues to grow, popcorn packaging machine is a juggernaut in the market's growth saga, touching on everything from marketing magic to ensuring product perfection, consumer convenience, and eco-friendliness. As the popcorn world expands, innovative packaging that ticks all these boxes is set to be a star player in the popcorn brand.

The types of popcorn packaging vary, each with its own set of advantages and disadvantages. Here are the most popular types:

This is the most basic and cheapest type of popcorn packaging. However, it's not the most effective in preserving the freshness of the popcorn.

A step up from plastic bags, popcorn tins are more expensive and are not airtight, which can lead to stale popcorn. They are also bulky, making them less ideal for shipping and retail display.

These are similar to typical chip bags, made from rollstock and sealed by a form fill seal machine. While popular, they have drawbacks such as not being able to stand up on shelves and lacking resealability after opening.

Considered one of the best options for popcorn packaging, stand up pouches can form a tight seal even after being opened. They are designed to stand upright on shelves, offering better visibility. These pouches also provide ample space for branding and are made from multiple layers of laminated barrier film to protect the popcorn from moisture, vapor, odor, and UV rays.

Each packaging type brings something unique to the table, whether it's cost-effectiveness, style points, or freshness factor. But if you're looking for the total package (pun intended), stand up pouches seem to have it all – they're like the superheroes of popcorn packaging in today's competitive snack market.

Choosing the right popcorn packing machine is critical for businesses. This section explores the different types of machines available, including automated and manual systems, and their respective uses.

Automated systems offer higher efficiency and are ideal for large-scale production. Manual systems, on the other hand, are more suited for smaller operations or specialized packaging needs.

We can now take it a step further and identify the packaging equipment for every type of packaging.

Manual or Semi-Automatic Bagging Machines: These machines are used for filling and sealing plastic bags. They can be operated manually or semi-automatically, where the operator fills the bag and the machine seals it with a twist tie or heat seal.

Automatic Filling and Sealing Machines: These are specialized machines designed to fill tins with popcorn and then seal them. They can be programmed for different tin sizes and are typically used in larger production settings.

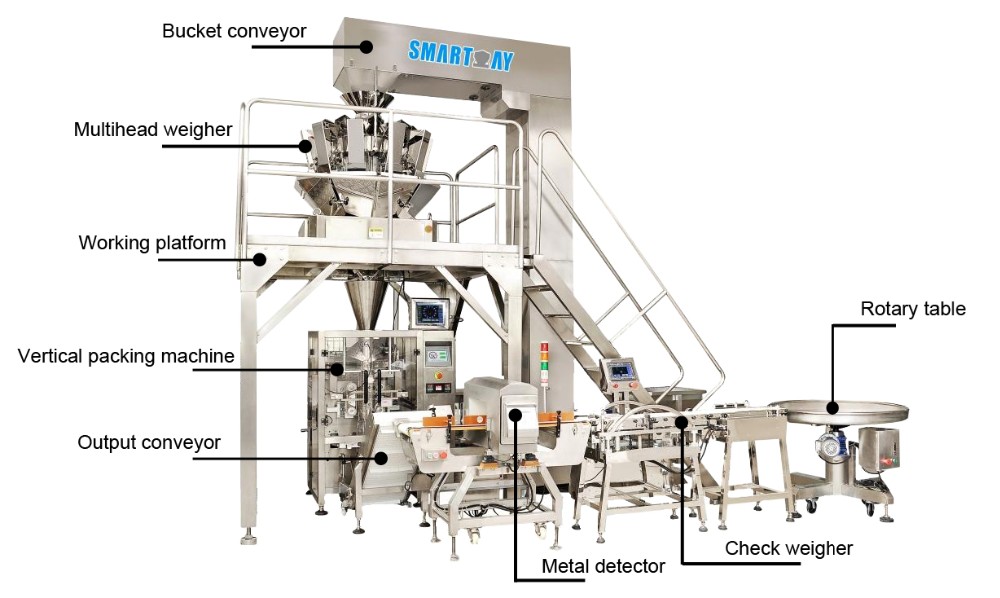

Vertical Form Fill Seal Machines: These machines are used for creating bags from rollstock material, filling them with popcorn, and then sealing them. VFFS machines are versatile and can produce a variety of bag length. They are commonly used for packaging snacks like popcorn.

Rotary Packaging Machines: These machines are designed for pre-made stand-up pouches. They open the pouch, fill it with popcorn, and then seal it. These machines equip with multihead weigher are efficient and can handle a range of pouch sizes and styles with different features like zippers.

For larger scale production, HFFS machines can be used to form, fill, and seal stand-up pouches from rollstock material.

Each type of popcorn filling machine is designed to optimize the packaging process for its specific type of packaging, ensuring efficiency, maintaining product quality, and meeting the production demands of the popcorn industry. The choice of machine depends on factors like the type of packaging, production volume, and specific requirements of the popcorn product.

Let's explore how integrating one of these innovative popcorn packaging machines can elevate your business. This part will spotlight the enhancements in efficiency and quality you can expect.

Ever thought of packaging heaps of popcorn in a flash? These popcorn packaging machines make that a reality. They're game-changers in ramping up production efficiency, trimming down time and labor expenses.

Want popcorn that stays fresh and delicious? It's all in the sealing. These popcorn filling machines seal the deal, literally, keeping your popcorn fresh and safe from contaminants, ensuring top-notch quality from the popping pot to the customer's hands.

Choosing the Perfect Popcorn Packaging Machine Picking the right machine is no small task for a popcorn venture. In this section, we dive into the key aspects to ponder and how to tailor the machine choice to meet your specific business needs.

Key Considerations: Think about your production volume, the space you have, and your budget. These are vital in picking a popcorn packing machine that fits just right.

Tailoring the Machine to Your Business: It's all about harmony – aligning the machine's prowess with your business goals. Whether you're running a charming little shop or a bustling production line, finding that perfect match is crucial.

Regular maintenance is vital for the longevity and performance of your popcorn packaging machine. This section outlines a routine maintenance schedule and common troubleshooting tips.

Adhering to a regular maintenance schedule ensures that the machine operates at optimal efficiency and helps prevent unexpected breakdowns.

Familiarity with common issues and their solutions is important for minimizing downtime and maintaining productivity. For more detailed steps, let's check our another blog: What Are Common Troubleshooting With Vertical Packing Machines?

Investing in a popcorn packaging machine involves various cost considerations. This section discusses the initial investment and long-term benefits.

The upfront cost of a popcorn packaging machine varies based on its type, capacity, and features.

While the initial investment may be significant, the long-term benefits, such as increased production efficiency and reduced labor costs, often justify the expense.

Customization allows businesses to tailor their popcorn packaging machines to specific requirements. This section explores available customization features and how they can be utilized.

Whether it's a specific bag size, branding, or special sealing methods, customization options enable businesses to meet unique packaging needs.

Discussing the range of customization features available, from software adjustments to hardware modifications, this section helps businesses understand their options and how they can enhance their packaging process.

Staying ahead of technological advancements is key to remaining competitive. This section looks into future innovations in popcorn packaging and their potential impact on the industry.

Discussing upcoming technological developments in popcorn packaging machines, such as AI integration and automated quality control systems.

Analyzing how these future trends could transform the popcorn packaging process, enhance efficiency, and meet evolving consumer demands.

Automation plays a significant role in modern packaging processes. This section explores the advancements in automation and their implications.

Delving into how automation has revolutionized popcorn packaging, from increased production speeds to improved consistency and quality.

Analyzing the effects of automation on labor requirements and overall efficiency in the popcorn packaging process.

As popcorn continues to be a favorite snack worldwide, the role of effective packaging in its distribution and consumption cannot be overstated. In embracing these innovative popcorn packaging machines and the advancements they bring, businesses are not only investing in a tool but are also paving the way for a more efficient, sustainable, and successful future in the popcorn industry.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved