Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Detergent Laundry Pod Washing Balls Capsule Packaging Machine Solution

Market Overview

Begin by discussing the growing demand for laundry pods, which have become increasingly popular due to their convenience, efficiency, and eco-friendly packaging. Highlight the expanding global market for single-dose laundry detergents and the importance of precise and reliable packaging in ensuring product quality and consumer satisfaction. Detergent packaging machine can solve this problem well.

Importance of Automation

Emphasize the role of automation in meeting market demands, particularly for manufacturers looking to enhance production efficiency, maintain product quality, and reduce operational costs. Mention how automation, especially in weighing and packaging, is critical in maintaining consistency and minimizing waste.

Introduction of Multihead Weigher Technology: Provide a brief overview of the multihead weigher packing machine technology, explaining how it has revolutionized packaging for a wide variety of products, including laundry pods. Highlight key features such as precision, speed, and versatility, which are crucial in packing sensitive items like laundry pods.

Customer Requirements and Challenges

Customer Needs

There are two types of secondary package in this project: can filling and pouch packing.

| Package | Can / Box | Pouch |

| Weight | 10 pcs | 10 pcs |

| Accuracy | 100% | 100% |

| Speed | 80 cans/min | 30 packs/min |

Key Challenges:

Product Fragility: Laundry pods are prone to damage during handling, making it essential to have gentle but precise machinery.

Weight Consistency: Ensuring that each pod or packet of pods meets right quantity to maintain product quality and comply with regulations.

Machine Solution

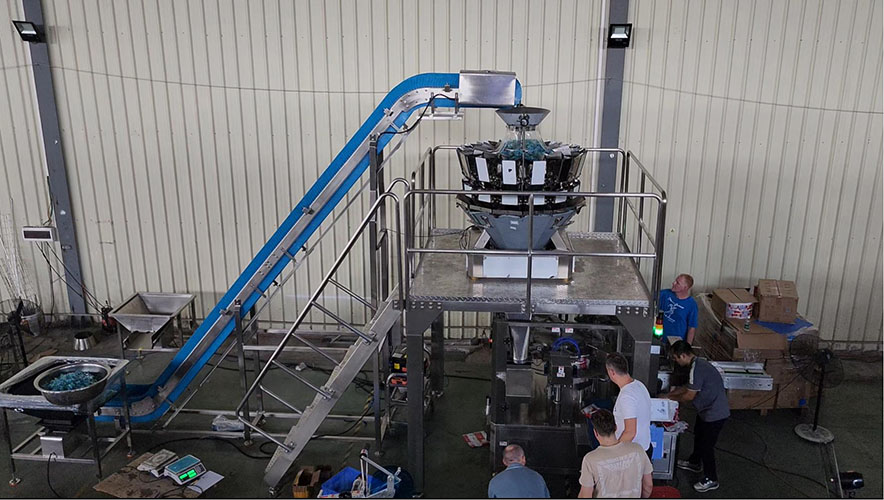

For Detergent Pouch Packing Machine Solution:

1. Incline conveyor

2. 14 head multihead weigher

3. Support platform

4. Rotary pouch packing machine

For Detergent Can Filling Machine Solution:

1. Incline conveyor

2. 20 head multihead weigher (twin discharge)

3. Can despenser

4. Can filling device

Key Features:

High Precision: Multihead weigher guarantees that each container is accurately weighed and counted, significantly reducing the likelihood of errors.

High-Speed Operation: Capable of packaging max 80 cans per minute, the machine keeps pace with the client's increasing production demands.

Customization Options: The multihead weigher detergent filling machine can fill 2 empty cans at the same time, which is tailored to the client's high speed needs.

Versatility: The machine can accommodate various packaging sizes, providing the client with flexibility in how they present their products.

Operational Efficiency

Performance Capabilities

The multihead weigher detergent packing machine has transformed the client's operational efficiency:

Speed and Output: The machine significantly increased the packaging speed, enabling the client to package up to 30% more units per hour compared to their previous setup.

Efficiency Gains: Automating the packaging process reduced reliance on manual labor, leading to lower labor costs and fewer human errors.

Product Handling: With its gentle handling features, the machine ensures that each laundry pod remains intact, preserving product quality throughout the process.

Integration

The multihead weigher seamlessly integrates with the client’s existing production line, connecting to form-fill-seal machines to create a fully automated packaging solution. This integration minimizes downtime and maximizes production output.

Impact on Costs

The increased efficiency has led to substantial cost savings. By reducing manual labor and material waste, the client has improved their bottom line while maintaining product quality.

Case Video

Conclusion

The case of our client illustrates the significant advantages of using a multihead weigher packing machine for laundry pods. With its high accuracy, speed, and operational efficiency, this technology has positioned the client for continued success in a competitive market.

As the packaging industry evolves, opportunities for innovation will continue to emerge. The multihead weigher stands at the forefront of this evolution, providing manufacturers with the tools they need to thrive.

For manufacturers looking to enhance their packaging processes, exploring solutions like the multihead weigher can lead to substantial improvements in productivity, cost savings, and product quality whether detergent filling machine or detergent pouch packing machine. Reach out today to discover how we can help you optimize your detergent packaging machine operations.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425