Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

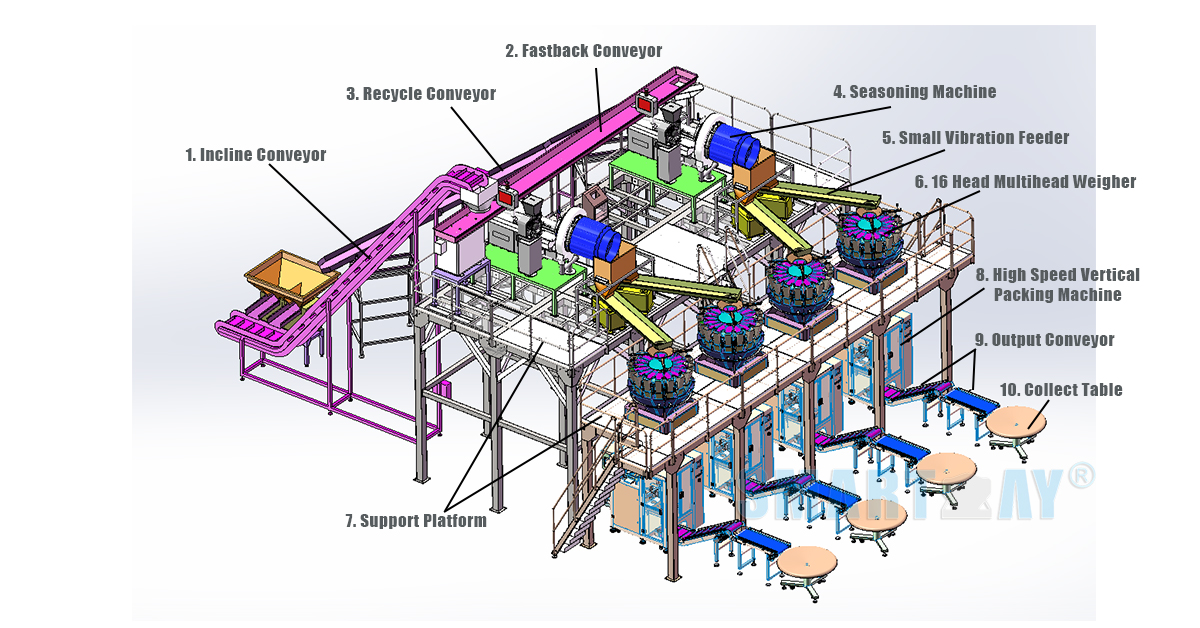

Unmanned Automatic Chips Packaging Machine System

In the ever-evolving landscape of production, our client has identified a pressing need to adapt and enhance their operations. With escalating production demands, it has become imperative for them to phase out their older machinery. Their aspiration is not just to modernize but to optimize: they are in search of advanced machines that not only streamline the production process but also minimize the workforce requirement and spatial footprint. This transition aims to marry efficiency with compactness, ensuring that they remain competitive and agile in today's fast-paced market.

In the competitive realm of packaging solutions, what we have offered to our clients truly sets a benchmark. Our innovative approach and meticulous attention to detail have not only differentiated us from other suppliers our customers have previously engaged with but have also left a lasting impression on them. The solution we provided is not just about meeting basic requirements; it's about exceeding expectations, pushing boundaries, and redefining standards. Our commitment to excellence and our drive to deliver unparalleled quality have resonated deeply with our clients, solidifying our position as a trusted and esteemed partner in their business journey.

1. Incline conveyor(1) directly connected to the front end of the frying line, no need for manual intervention to dump the material to the elevator, saving workers.

2. If the corn chips are delivered to the second seasoning machine and still not needed, they will be sent to the end of the ramp back to the mouth via recycle conveyor, and then re-feed to the large vibrating feeder on the ground to continue the cycle of feeding, which can form a perfect closed loop.

3. Sprinkle seasoning online, according to the different flavors of the orders need to adjust the production, save time.

4. Use of fastback conveyor for feeding and distributing, reducing the breakage rate of corn flakes, and improving the ability of quick cleaning, compared with the belt feeding will be convenient to clean and improve the hygiene.

5. Fast speed, the actual production capacity reaches about 95 packages/minute/set x 4 sets.

"We integrated the new packaging machine into our production line, and the advantages it offers are truly remarkable." Said from our customer, "These machine are running stablely cycling, they are work well with each other, machine quality from Smart Weigh is no worse than European machines. Besides, Smart Weigh team told us they can provide auto cartoning, sealing and palletizing system if we need higher grade of automation."

| Weight | 30-90 grams/bag |

| Speed | 100 packs/min with nitrogen for each 16 head weigher with high speed vertical packing machine, total capacity 400 packs/min, it means that 5,760- 17,280 kg. |

| Bag Style | Pillow bag |

| Bag Size | Length 100-350mm, width 80-250mm |

| Power | 220V, 50/60HZ, single phase |

As technology continues to advance, we, Smart Weigh can expect even more innovations in the realm of automated chips packaging Machines. In conclusion, the move towards unmanned chips packaging machine is not just a trend but a necessary evolution for large-scale manufacturers in the food industry. As demonstrated by the real-world examples, embracing automation offers numerous benefits, from increased efficiency to cost savings.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425