Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

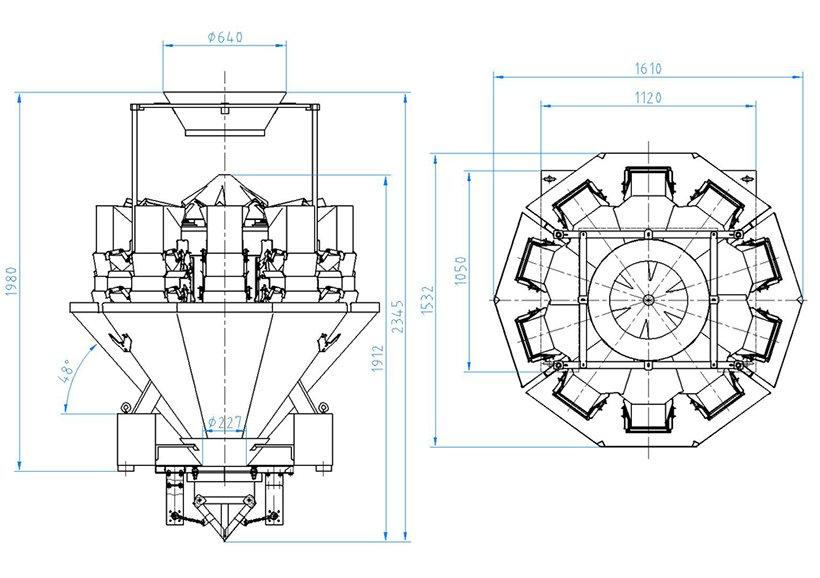

Model | SW-ML10 |

Weighing Range | 10-5000 grams |

Max. Speed | 45 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 0.5L |

Control Penal | 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 10A; 1000W |

Driving System | Stepper Motor |

Packing Dimension | 1950L*1280W*1691H mm |

Gross Weight | 640 kg |

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Four side seal base frame ensure stable while running, big cover easy for maintenance;

◇ Modular control system, more stability and lower maintenance fees;

◆ Rotary or vibrating top cone can be selected;

◇ Load cell or photo sensor checking to satisfy different requirements;

◆ Preset stagger dump function to stop blockage;

◇ 9.7' touch screen with user friendly menu, easy to change in different menu;

◆ Checking signal connection with another equipment on the screen directly;

◇ Food contact parts disassembling without tools, which is easier to clean;

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved