Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

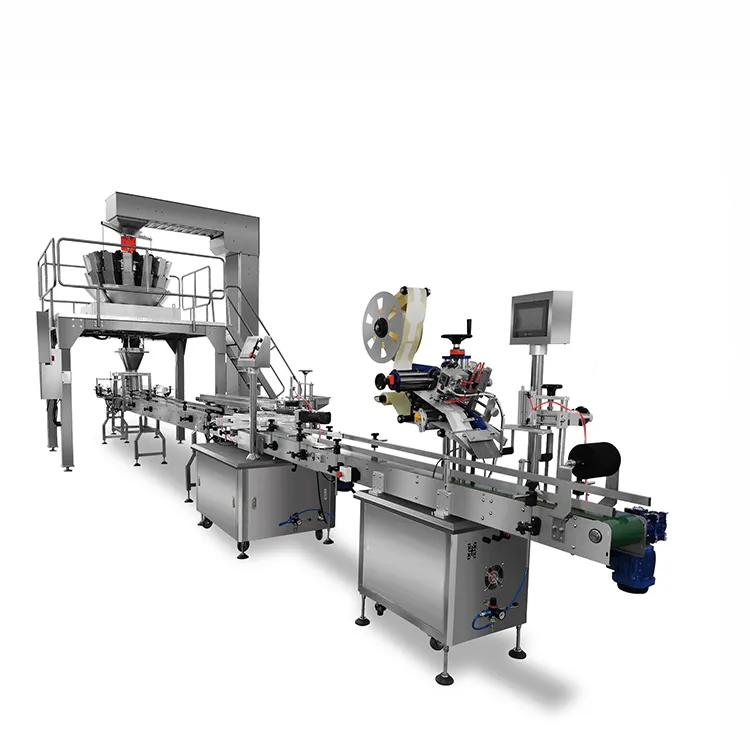

If you're packaging granular products, you know that finding the right jar filling machine can make or break your operation. With the variety of jar filling machine manufacturers and packaging machine options on the market, it can be overwhelming to determine which is right for your needs. But with the right filling machine, you can ensure that your products are accurately and efficiently dispensed into containers, maintaining the quality and hygiene of your granular products.

In this article, we'll explore the world of jar filling machines and provide you with the information you need to select the right machine for your business. From understanding the different types of these machines available to consider the features and benefits of each, we'll help you make an informed decision about the equipment you need to take your packaging operation to the next level.

Understanding Your Product: A Key Consideration When Selecting a Jar Filling Machine

Choosing the right jar filling machine is critical to maintaining the quality and integrity of your product. Before making a decision, it is vital to understand your product details.

The Quantity of Your Product

The quantity of your product is essential when selecting the right filling machine. This factor determines whether a piston or gravity filler suits your product.

Environmental Considerations

Certain products, such as pharmaceutical or chemical products, require a specific environment for filling. Aseptic filling within a sterile environment may be necessary for biotech or pharmaceutical products, while chemical products require fire-retardant and explosion-proof systems. Understanding any such environmental requirements is essential before deciding on your filling machine.

Container Considerations When Selecting a Granular Filling Machine

Selecting the right granular filling machine is crucial to maintaining the quality and integrity of your product. However, it is also essential to consider the type of container you will use for your product. The next part will discuss the key container considerations when selecting a jar filling machine.

Type of Container

The type of container you will use for your product is essential when choosing a filling machine. Will you be filling flexible pouches, cans, or bottles? Defining the type of container will help narrow down the options.

Container Size, Shape, and Material

If you will be filling bottles, what is the size, shape, and material? Glass or plastic? What type of cap or lid is required? Understanding these details will help you select a machine that can handle the size and shape of your container and dispense the product accurately.

Labeling Solution

Do you require a labeling solution as well? Some filling machines offer integrated labeling solutions, while others may require a separate labeling system. Defining this need beforehand will make discussing your plans with your packaging manufacturers and supplies provider easier.

Flexibility

Your filling line should offer flexibility. It should handle a range of bottle sizes and shapes with minimal changeover time. This feature can help you save time and resources in the long run.

Choosing the Right Level of Automation for Your Jar Filling Machine

Selecting the right level of automation is essential when choosing a jar-filling machine. Defining the production and growth potential level will help you calculate the speed and capacity needed to meet production demands. The next parts discuss the key considerations for choosing the right level of automation for your filling machine.

Level of Production

Defining the level of production is crucial when selecting a jar filling machine. Calculating the number of bottles needed per day, week, or year will help you determine the speed and capacity per minute/hour required for the machine.

Growth Potential

As your operations grow, your Jar filling machine should have the ability to grow with it. Upgradable machines and the ability to accommodate more filling heads should be considered when selecting a machine.

Manual, Semi-Automatic, or Fully Automated

The number of bottles per minute needed to reach production demands will help you decide if a manual, semi-automatic, or fully automated packaging manufacturer is right for you. For small production runs, semi-automatic or manual filling machines may be appropriate. As production increases, upgrading to a fully automated system can increase the filling rate and reduce operator interaction.

The Importance of Filling Accuracy in Automated Packaging Systems

Filling accuracy is critical in packaging manufacturers, and automated filling machines offer a key advantage in achieving precise and consistent filling.

Benefits of Accurate Filling

Under-filled or over-filled containers can lead to customer complaints and unnecessary waste. Automated filling machines equipped with PLCs can ensure precise filling, eliminate overflow, save products, and reduce expenses on cleaning and maintenance.

Final Thoughts

Selecting the right jar filling machine manufacturer is crucial for any granular packaging business. When choosing the best machine for your enterprise, you must consider your product details, container specifications, level of automation, filling accuracy, and long-term business goals.

By following the guidelines discussed in this article, you can select a machine that will not only fulfill your current needs but also have the potential to grow with your business. Thanks for the Read!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved