Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

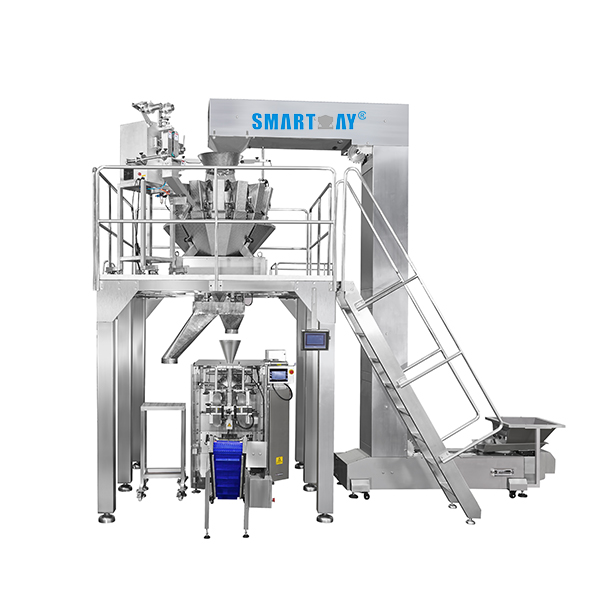

The Vertical Form Fill Seal (VFFS) machine is a unique and effective solution in the constantly changing field of packaging equipment. This automated machinery is essential to a variety of industries, including medicines and food and beverage. We'll examine the functionality, salient characteristics, and many uses of VFFS machines.

Vertical form fill seal packaging machines can be categorized into two main types based on their feeding and packing processes: A Vertical Form Fill Seal (VFFS) machine is a type of bagging machine designed to streamline the packaging process by integrating three essential functions: forming, filling, and sealing.

In this type of VFFS packing machine, the product is manually fed into the hopper or filling system, but the rest of the packaging process - forming, sealing, and cutting - is fully automated. This configuration is often suitable for smaller production lines or businesses handling products that require careful or delicate manual loading.

Manual Product Loading: Workers feed the product into the machine by hand, which is ideal for irregular-shaped or fragile items.

Automated Packing Process: Once the product is loaded, the machine automatically forms the bag, seals it, and cuts the finished product, ensuring efficiency in the sealing and packaging stages.

Since the feeding process is manual, the machine is typically more affordable and suitable for small-scale operations.

In the more advanced type, the VFFS packaging machine is fully automated, performing not just the packaging but also the weighing and filling of the product. This type is widely used in industries where speed, accuracy, and high throughput are essential, such as in food packaging and bulk product handling.

Integrated Weighing System: The machine includes scales or multihead weighers that automatically measure the product to precise amounts before filling.

Automated Filling: The product is dispensed into the formed bag without the need for manual intervention.

Fully Automated Process: From weighing to sealing and cutting, the entire process is streamlined, reducing labor costs and increasing production speed.

Horizontal Seals: The machine can produce pillow bags efficiently with both back and horizontal seals, ensuring versatility in packaging.

This type of machine ensures accurate product measurement and packaging, minimizing product waste and maximizing efficiency.

Understanding the features of vertical form fill seal packaging machines can help businesses select the right model for their flexible packaging needs. Here are some standout characteristics:

1. High-Speed Operation

VFFS machines are designed for rapid packaging, capable of producing up to 200 bags per minute depending on the product and bag size.

2. Versatility in Packaging Materials

Material Compatibility: VFFS packaging machines are designed to meet various flexible packaging needs, capable of handling different packaging films, including laminates, polyethylene, and biodegradable materials.

Bag Styles: The machines can produce different bag types such as pillow bags, gusseted bags, and block-bottom bags.

3. Advanced Control Systems

Modern vertical FFS machines come equipped with:

Touchscreen Interfaces: For easy operation and parameter adjustments.

Programmable Logic Controllers (PLCs): Ensure precise control over the packaging process.

Sensors and Feedback Systems: Detect film tension, seal integrity, and product flow to minimize errors.

4. Integration Capabilities

Weighing and Dosing Equipment: Seamlessly integrate with multihead weighers, volumetric fillers, or liquid pumps.

Ancillary Equipment: Compatible with printers, labelers, and metal detectors for enhanced functionality.

5. Hygienic Design

Especially important in food and pharmaceutical industries, VFFS packing machines often feature stainless steel construction and easy-to-clean surfaces to ensure hygienic conditions and securely seal bags.

The adaptability of a VFFS packaging machine makes it suitable for packaging a wide array of products:

Snacks and Confectionery: VFFS packaging machines are widely used in the food industry for packaging snacks, confectionery, dry goods, and frozen foods. Chips, nuts, candies.

Dry Goods: Rice, pasta, cereals.

Frozen Foods: Vegetables, seafood.

Tablets and Capsules: Packaged in unit doses.

Powders: Protein powders, dietary supplements.

Granules and Powders: Detergents, fertilizers.

Small Hardware: Screws, bolts, small parts.

Dry Kibble: For cats and dogs.

Treats and Snacks: Packaged in various sizes.

At Smartweigh, we are committed to delivering top-of-the-line VFFS packing machines that cater to your specific needs.

1. Customized Solutions

We understand that every product is unique. Our team works closely with you to customize machine settings, ensuring optimal performance for your packaging requirements.

2. Innovative Technology

Our machines incorporate the latest advancements in automation and control systems, providing you with efficient and reliable operation.

3. Exceptional Support

From installation to maintenance, our dedicated technical support team is here to assist you every step of the way.

4. Quality Assurance

We adhere to strict quality control measures, guaranteeing that our machines meet international standards and deliver consistent results.

The Vertical Form Fill Seal machine is a vital asset for any business looking to enhance packaging efficiency and product presentation. Its operation is a blend of precision engineering and innovative technology, offering numerous features that cater to a variety of applications.

By choosing Smartweigh's VFFS machines, you invest in quality, reliability, and a partnership dedicated to your success.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved