Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Why choose thermoforming packaging machine for cooked food packing?

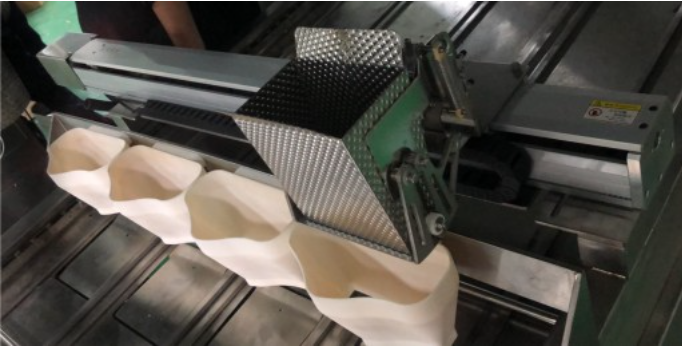

For a Danish client who supplies ready-to-eat food to restaurants and supermarkets, Smart Weigh recommended an auto horizontal thermoforming packing solution for ready meal. The issue of complicated material composition, too greasy, and too sticky materials can be resolved by thermoforming packing machine.

Thermoforming plastic stretch film packaging machines, which are frequently used to package prepared foods, have features such as tray dispensing, filling, vacuuming, gas flushing, and heat sealing.

1) SUS304 stainless steel is used to assure food's safety and hygiene.

2) We provide adjustable tray dispensers for trays in a variety of sizes and shapes. The device is simple to install and maintain.

3) Highly efficient feed dispenser allows for high-volume filling in small production workshop by feeding various meals and sauces on a single packaging line while saving space.

4) Functions of vacuuming and gas flushing successfully prevent material from rotting and deteriorating and extend shelf life. Heating temperature and heating duration can be flexibly adjusted according to the properties of food, material and thickness of package. Stable operation of tray sealing machine, strict control of length and position of the rolled film, no offset, no misalignment, precise sealing and cutting positions. Rolled film is durable, well-sealed, and prevents liquid spills and contamination.

5) High compatibility, can be equipped with liquid pumps for filling ketchup, soup, sauces, etc. And can be integrated with multi-head scraper gate combination weighing machine for weighing oily materials.

Automated thermoforming vacuum packing line saves labor. Low breakage rates, high material usage rates, and a reduction in waste from trays and film rolls. Lower cost of production while raising profit margin.

Thermoforming vacuum packaging system in flexible film for cooked food, like boxed rice, sausages, pickles, steak, etc.

Additionally, it is commonly utilized in a variety of trays, including foam trays, paper trays, plastic trays, and round bowls.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425