Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh's potato chip vertical packaging machine has been well received by overseas customers for its high efficiency and effective labor cost savings. The vertical packing machine is more affordable and takes up less space than the rotary packing machine.

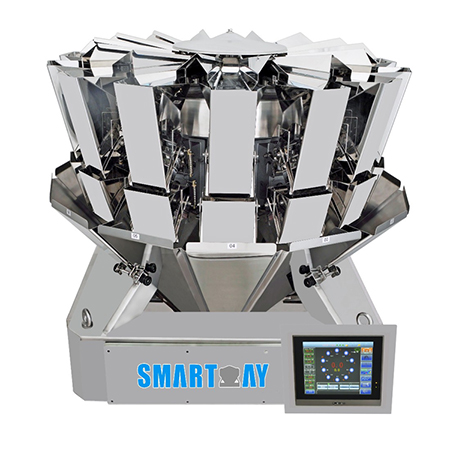

The potato chip packaging line consists of a Z-bucket conveyor, a multi-head weigher, a supporting platform, a vertical form fill seal packaging machine, an output conveyor, a rotary table, a nitrogen filling machine, etc.

The chips packing machine is the perfect solution to efficient packaging of chips with little fuss and effort. We can see it is consist of above machine and the main machine is multihead weighers and vertical form fill seal machine. Usually customers choose 14 head multihead weigher for higher speed, the bucket conveyor feed the bulk chips to multihead weighing machine, multi head scale auto weigh and fill the chips as preset weight then fill into vffs. Vertical packing machine make the pillow bag with nitrogen from the roll film and seal it. Then the chips packets are finished!

Detailed workflow of chips packing machine:

1. Start by adding the material to the vibrating feeder.

2. A Z conveyor will convey the product to the multi-head weigher's hopper.

3. The multi-head weigher handles combination calculation.

4. The products that reach the target weight will be filled.

5. The vertical packing machine's servo pulling film system provides rolled film, cuts it into the desired shape, and seals it.

6. The machine will discharge the packaged goods, which will then be transported to the platform.

.

Crispy goods like potato chips need nitrogen filling to keep them from oxidizing and spoiling.

Two workers are all that are needed to operate a fully automatic VFFS packaging system, which can pack at least 4200 bags of potato chips in an hour by operating the touch screen.

Snacks like potato chips are frequently accessible in large supermarkets and are typically sold for a low price in pillow bags with a standard shape. Additionally, linking pillow bags can be hung from the shelves.

In addition to packing potato chips, a vertical packaging line can also pack various foods including popcorn, chocolate, candy, maize chips, banana chips, shrimp sticks, and others.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved