Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

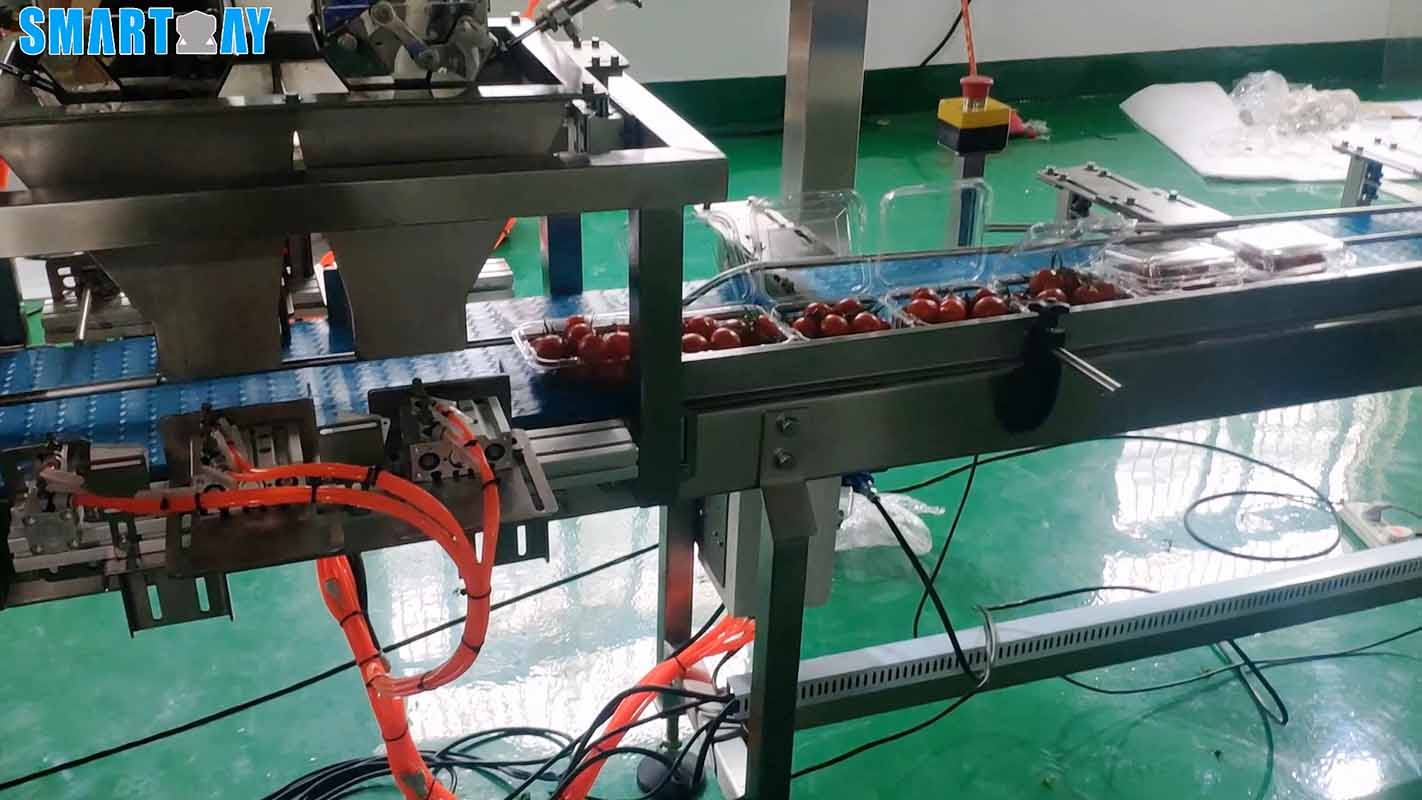

There is a large variety of packaging machines available from smartweighpack. These machines are meant to automate the packaging processes that come after the primary packaging stage of the goods. No of the scope of your undertaking, smartweighpack can provide you with meat packaging machines suitable for either low- or high-volume manufacturing.

What exactly is a Meat Packaging Machine?

The heart of the meat packaging system is the weigher and packing machine. The condition of meat is quite different with snack food. Fresh meat is sticky; sauce meat is sticky and with water, frozen meat is hard and etc., custom weighers are needed for different condition of meat to ensure the accuracy and speed.

During the manufacturing, distribution, and storage phases of a product's lifecycle, the packaging is there to ensure the product remains in pristine condition at all times (tertiary packaging).

Its purpose is to protect the meat from dirt and potential contamination during shipment by packed it in a thin polyethylene film. Organizations that do not use a packer can waste up to three times as much film as those that have.

These machines can collaborate with an original wrapping machine to automatically apply a protective film—bubble wrap, for instance—on the package for added strength and security.

Almost every step of the meat-processing process relies heavily on cutting applications. The effectiveness and profitability of your meat processing activities depend on the quality of the machinery you use to do anything from slicing the meat into different parts to cutting and packaging. Please read on, as we cover every facet of this meat-packing machine for industrial use.

Types of Meat Packaging Machine

Various production practices exist that guarantee untampered meat packaging and delivery to the consumer. Here, we've detailed the many varieties of meat packing machines and the various applications to assist firms zero in on the precise machinery they require.

Sealing machines for clamshell packaging are considered to be the most effective available. Your production of blister or clamshell packaging can benefit from the use of these dependable workhorse machines, which offer effective solutions. You can choose the model that best meets your requirements for packaging from among a large variety of options designed for varying degrees of productivity. Each and every one of Smartweighpack's machines is guaranteed to deliver a dependable performance, an easy-to-use interface, and a long-lasting durability.

Blister Packing Machine

A blister packaging machine is a type of packaging machinery that is used to form blisters or pockets out of thin sheets of material.

The main benefits of using a blister packing machine are that it can improve the shelf life of products and provide better protection against tampering and moisture damage. Additionally, blister packaging can make products more visible and easy to store. Depending on the style of the packaging, these containers are perfect for securing, transporting, containing, and exhibiting meat on shelves or pegs, respectively.

The rotary packing machine has the capability of integrating many pre-made pouch packaging phases into a single or eight automated process. These steps may include bag feeding, bag opening, filling & sealing, completed product conveying, and others.

Packaging equipment that operates at a fast rate of speed includes the rotary packing machines. Its modular design makes it possible for it to link with a wide variety of fillers. Therefore, it is appropriate for meat and sees widespread application in the industry that deals with processing meat.

In addition, smartweighpack rotary packing machines are simple to operate and are able to pack a wide range of ready-made bags, including doypack pouch, flat bottom bags, gusseted pouches, or quad seal pouches. These machines may also be used to pack a variety of other pre-made bags.

The Vertical Form Fill is a machinery that functions with a high degree of flexibility, which makes it suitable for catering to the packaging needs of a variety of industries, including those related to the production of meat. Because they are controlled by PLCs and have touch-screen interfaces, our VFFS systems are exceptionally user-friendly.

The machine is robust and has a high output, all while operating in an extremely quiet manner. Because it requires very little upkeep, is constructed very robustly, is made from high-quality components, and is consequently exceptionally long-lasting.

Advantages of Buying Meat Packaging Machine

Your business stands to gain many advantages from automating the product packaging process. A few of these benefits are more evident and concrete than others, but they all contribute in their own unique ways to the success of your business and the amount of money you bring in at the end of the day.

● Helps Lower the Chance of Developing Repetitive Strain Injuries

● Acceleration of the Manufacturing Process

● Eliminate Potential Bottlenecks

● Get Rid of Your Downtime

● Increased Product Sales Thanks to a Lower Pricing Structure

Final Words

The term "meat packaging machine" can have a variety of meanings to a variety of people, and the meaning that is appropriate for you entirely relies on the market that you are operating.

It could mean putting meat into containers for some people, while for others it could mean binding together big sheets of material and wrapping them in plastic. Because of the wide variety of meat products, the packaging machines used for them also come in a wide variety, and they frequently need to be custom-made in order to satisfy the needs of individual businesses.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved