Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

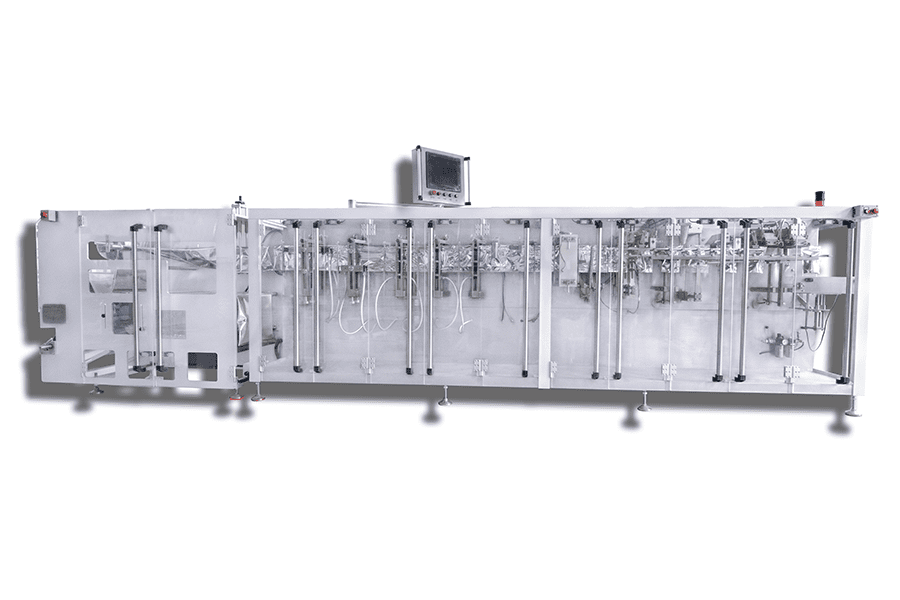

HFFS (Horizontal Form Fill Seal) machine is a packaging equipment commonly used in the food, beverage, and pharmaceutical industries. It is a versatile machine that can form, fill, and seal various products such as powders, granules, liquids, and solids. HFFS machines come in making different bag styles, and their design can vary depending on the packaged product. In this blog, we will explore components of an HFFS machine, how it works, advantages for packaging and applications.

The Components of an HFFS Machine

The components of an HFFS machine are critical to its functionality and overall performance.

· The film unwinds section feeds the packaging material into the machine, either from a roll or a pre-cut sheet.

· The material is molded into the desired shape using heat and pressure in the forming section.

· Cutting system separates the individual packages from the continuous film.

· The filling station is where the product is dispensed into the pouches, either by gravity or with the help of a dosing system.

· The sealing station is where the packaging is hermetically heat sealed.

Each of these parts plays a crucial role in the HFFS machine's ability to efficiently and accurately produce high-quality packages for various products.

How HFFS Machines Work

HFFS machines are designed to automate the process of packaging products quickly and efficiently.

The process begins with feeding the packaging material, a roll film, into the machine's film unwind section. The material is then moved through the forming section, where it is shaped into the desired package design.

Next, the cutting system separates the individual packages from the continuous film. HFFS machines are highly versatile and can customize many bag styles, making them popular in many industries.

Finally, the product is dispensed into the formed packaging at the filling station. The packaging is then sealed at the sealing station, which can use heat or ultrasonic technology to create an airtight seal.

Advantages of HFFS machine

Cut Costs

Investing in a HFFS packaging machine can bring significant economic benefits. It's versatile and ideal for packaging anything from granules and chemicals to grains and powders. If you pack multiple sizes of product, you can save on raw material costs by using individual packaging rolls, which are less expensive than pre-made bags. You also don't have to deal with discarding any package trims, as each bag created by the form fill seal bagger fits the exact specified volume of the product in question.

Wide applicability

Applicable products are diverse, involving food, fresh vegetables, daily necessities, hardware and electronic products, toys, etc. The length of the wrapping paper can be adjusted arbitrarily, one machine is multi-purpose, and the applicability is very wide.

Easier cleaning and maintenance

In the past, less advanced horizontal form fill seal machines were cumbersome to install and time consuming to operate. Today's models are more compact, made of higher quality materials, have fewer moving parts, and only require annual maintenance. This means you can extend product run time and quickly clean the machine between runs. You don't have to have separate machines for different sized bags because one machine can now do the work of several.

Applications of HFFS Machines

HFFS machines are widely used in various industries for packaging different types of products. Snack food, cereals, candy and etc. are a common application for HFFS machines because they require fast and efficient packaging.

Packing powder is another industry where HFFS machines are utilized, as they can handle a range of powder products with customize package style. In the cosmetics industry, HFFS machines are used for packaging products such as lotions, creams samples.

HFFS machines are also commonly used in the pharmaceutical industry to package pills, tablets, and capsules. The advantages of using HFFS machines for these applications include increased production speed, reduced labor costs, and improved product quality and consistency.

Choosing the Right HFFS Machine for Your Business

Choosing an HFFS machine that can handle your production volume needs is important, whether a low, medium or high-volume machine. The product type and packaging material should also be considered, as different machines are designed to handle specific products and materials. Other factors to consider when choosing an HFFS machine include the following:

· Pouch Material

· The level of maintenance needed

· The cost of the machine

· Nature of the Product

· Product Dimensions

· Speed Required

· Filling Temperature

· Pouch Dimension

By carefully considering these factors, you can ensure that you select the right HFFS machine to meet the specific needs of your business.

Conclusion

In conclusion, HFFS machines are essential for packaging products quickly, efficiently, and with high quality. By understanding the components and workings of horizontal form fill seal machine, their applications, and how to choose the right machine for your business, you can make an informed decision about integrating this technology into your production line. Whether you are packaging snack foods, pet food, cosmetics, or pharmaceuticals, HFFS packaging machines can help you improve your productivity, reduce labor costs, and increase the consistency and quality of your products. Suppose you want to incorporate HFFS machines into your business. In that case, we encourage you to explore the options available and contact a trusted provider to help you find the right solution.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved