Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Turnkey packaging machine systems have become a cornerstone in the world of manufacturing, offering a streamlined, efficient approach to packaging. These systems, known for their ready-to-operate status upon installation, are increasingly popular in industries where packaging is a significant part of the production process. In this article, we delve into what turnkey packaging systems are, their components, advantages, and much more.

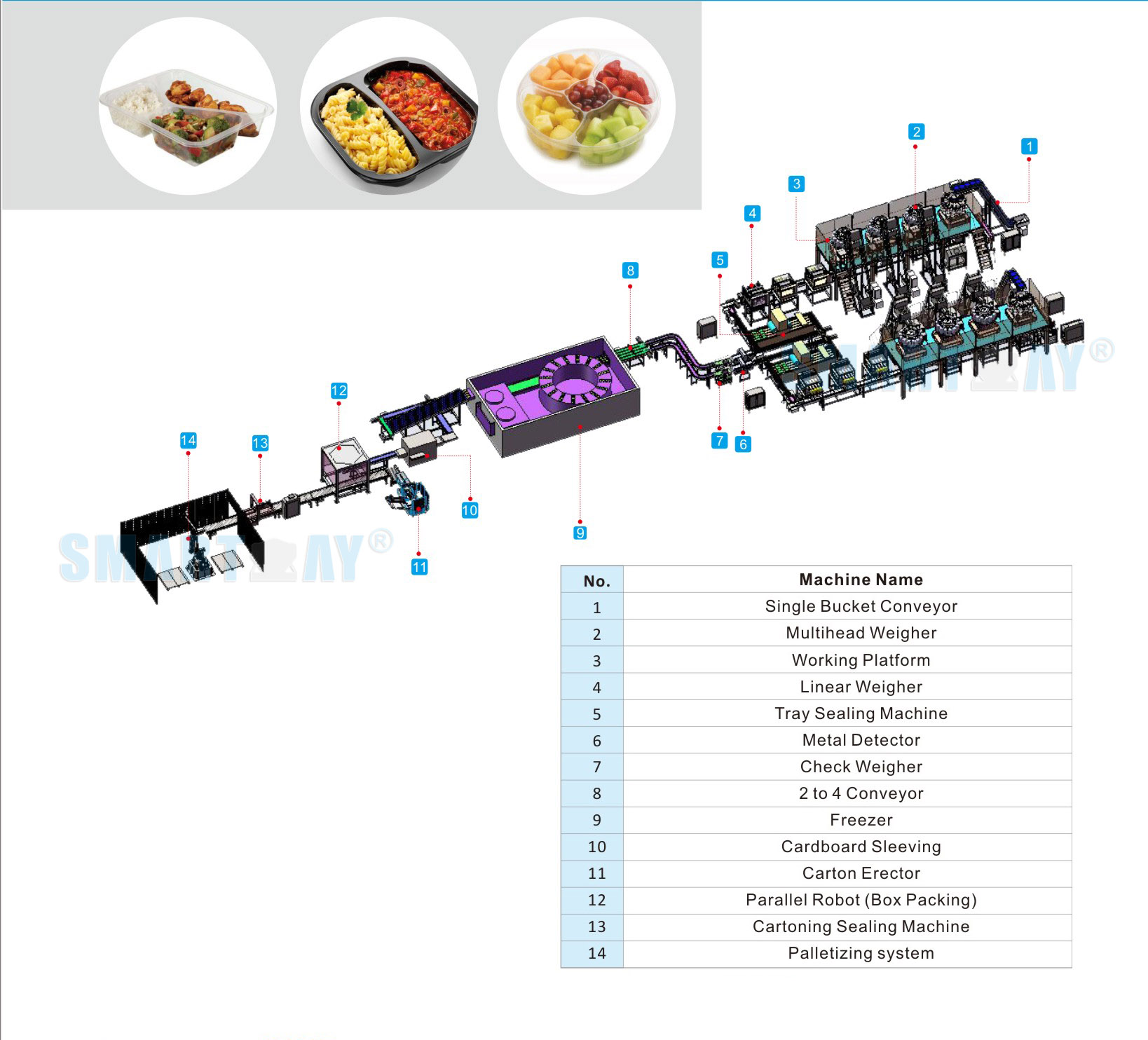

A "turnkey solution" in packaging refers to a system that is sold as a complete package from A to Z. Traditional packaging systems often focus on machines that perform only one or two specific functions. In contrast, our turnkey solutions offer a comprehensive approach, covering the entire packaging process from product weighing and packing to product palletizing. This integrated strategy streamlines operations, enhances efficiency, and provides a more cohesive experience than traditional, function-specific packaging machines.

At the heart of a turnkey packaging system are the core machines which include feeding machine, weigher and filler, packer, cartoner and palletizing. Complementing these are auxiliary equipment like conveyors, printers, labeling machines and inspection machines, all seamlessly integrated to ensure smooth operation.

Feeding machine is the part at the beginning of the packaging line, playing a pivotal role in the smooth operation of the entire process. These machines are expertly designed to handle the task of efficiently and consistently feeding products into the weigher, ensuring that the packaging line maintains a steady flow.

During normal production scenarios, the feeding machine is as the feed conveyor. This setup is ideal for standard operations where the volume of products being processed is within the typical range. However, when the production scale increases, and there's a need to handle larger volumes of products, the feeding machine transforms into a more complex system, designed not just for conveying but also for distributing and feeding the products.

This dual functionality of the feeding machine - as a conveyor in standard operations and as a distributor and feeder in larger productions - underscores its adaptability and importance in the packaging line, ensuring efficiency and effectiveness regardless of the production scale.

In contemporary packaging lines, weighing and filling machines are essential parts that guarantee uniformity, accuracy, and efficiency in the packaging process. There are various types of machine designed to handle a wide variety of products, ranging from liquids and powders to granular and solid items.

Volumetric fillers for consistent volume-based dispensing small granule

Linear weigher for powder and granule products such as seasoning, detergent powder, rice, sugar and beans.

Multihead weigher is more flexible, it has different models for granule, meat, vegetables, ready meals and even hardware.

Auger fillers ideal for precise measurement of powders

Lobe fillers for thicker, viscous substances, and piston fillers suited for thin, free-flowing liquids.

In entire packaging system, packing machines are the partner of weighing filling machines. The variety of packaging types, from bags and premade pouches to jars and cans, requires an array of specialized packing machines, each uniquely tailored to suit specific packaging needs.

When it comes to bag packaging, automated bagging machines are at the forefront, they are adept at handling a variety of bag types from the film roll, including pillow, gusseted, quad bag and more. They seamlessly perform tasks of forming, filling, and sealing bags, showcasing a remarkable blend of efficiency and precision. Their versatility extends to accommodating different materials like plastic, foil, paper and woven and various bag sizes and designs, making them invaluable across diverse industries.

For premade pouches, the machine is with pouch picking up, opening, filling and sealing function. These machines expertly manage the task of filling premade pouches with products before sealing them securely. Designed to handle various pouch materials and formats, such as stand-up or flat pouches, 8 side seal pouch, zipper doypack and more.

Jars and cans require their own dedicated container packing machines. These machines are crafted to cater to the needs of rigid containers, ensuring that jars and cans are filled, sealed and capped with the utmost efficiency. They feature unique handling and sealing mechanisms, such as rotary fillers for round containers and inline fillers for others, along with diverse sealing techniques like screw caps and can seaming. These machines are particularly crucial in preserving the integrity and extending the shelf life of food and beverage products, incorporating methods to maintain freshness and prevent contamination.

These labels carry essential information, such as product details, branding, barcodes, and regulatory information, all of which are vital for both the consumer and the manufacturer. The type of labeling machine used varies significantly depending on the packaging form, as each type of package has unique requirements for label application.

The labeling device will be installed in the vertical packing machine, stick the label on film before vffs form the pillow bags.

Usually the labeling machine for pouch will be set in the front of pouch packing machine. The pouch surface is smooth, which is good for accurate labeling.

It is an independent labeling machine for jars package. You could choose top, bottom or side labeling machine depends on your requirements.

The final step involves preparing the product for shipping and distribution. This includes case packing, where products are packed into boxes, and palletizing, where boxes are stacked and wrapped for shipment. End-of-line automation might also include shrink wrapping or strapping, adding an additional layer of protection during transit. These systems are designed for efficiency and reliability, ensuring products are ready for the journey to the customer.

The primary advantage of turnkey systems is their ability to significantly boost efficiency and productivity. By having a system designed to work cohesively, food manufacturers can achieve a higher output with consistent quality. Furthermore, these systems often come with reliability that reduces downtime and maintenance costs.

One of the key strengths of turnkey packaging systems is their adaptability. Manufacturers can customize these systems to meet specific industry needs, whether it's for food and beverage, pharmaceuticals, or cosmetics. By examining case studies, we see how customization plays a pivotal role in meeting diverse packaging demands.

Automation is a driving force in the effectiveness of turnkey packaging systems. With technologies like AI and robotics, these systems not only reduce the need for manual labor but also enhance precision and speed, leading to cost savings in the lon g run.

Sustainability is increasingly important in packaging. We'll explore how turnkey systems are adapting to use eco-friendly materials and processes, reducing the environmental impact of packaging operations.

Turnkey systems are not one-size-fits-all; they vary significantly across industries. This part will look at how these systems are used in key sectors like food and beverage, pharmaceuticals, and cosmetics, focusing on their specific requirements and challenges.

The packaging industry is constantly evolving with technological advancements. We'll examine the recent innovations in turnkey systems and predict future trends, emphasizing how these developments could shape the packaging industry.

Despite their advantages, turnkey systems face unique challenges. Many machine manufacturers are only focusing their own products, if you wanna get a complete packaging system, you have to contact many suppliers, keep communication and make a selection. This step is costly in terms of manpower and time.

But in Smart Weigh, we offer turnkey packaging solutions from A to Z, tell us your automation request, we will share you the right solution.

Selecting the right system is crucial. This part will offer guidance on what factors to consider, such as size, scalability, and technology, and provide tips for effective selection and procurement.

We'll speculate on the future of turnkey systems, considering evolving market demands and anticipated technological developments. This forward-looking perspective will give readers an idea of what to expect in the coming years.

In conclusion, turnkey packaging systems represent a significant leap forward in the world of manufacturing, offering comprehensive, efficient, and customizable solutions for diverse packaging needs. These systems, integrating various components like feeding machines, weighers, packers, and labeling machines, bring together the entire packaging process under one streamlined operation. Their adaptability to different products and packaging types, coupled with the advantages of automation, significantly enhances productivity and consistency in output.

As technology continues to evolve, so too will turnkey packaging systems. Anticipating future trends and innovations, these systems are poised to not only meet the current demands of the packaging industry but also adapt to emerging challenges and opportunities. For businesses looking to invest in a packaging system, turnkey solutions offer a holistic, efficient, and future-oriented approach, ensuring they stay competitive in a rapidly evolving marketplace. With the guidance provided on selecting the right system, businesses are well-equipped to make informed decisions that will drive their success in the years to come.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved