Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Multihead weighers are efficient machinery that has made weighing products in any factory much easier. While it is impressive machinery, there is no denying that it does come for a hefty.

Hence, before investing this machine, people must understand the dynamics and what problem should be paid attention to when installing and using a multihead weigher.

If you are someone who wants to know the points that should be considered before investing in this machinery, then you have landed at the right place.

The Factors to Consider Before Installing and Using a Multihead Weigher

When buying machinery, consumers invest a large amount of money; hence, before buying a product, they want to ensure that what they buy is just the best.

Similar is the case for a multihead weigher. Before buying this machinery, it is essential to understand the problems that might arise and factors to consider that help avoids them. Here are some factors to consider to buy a multi head weigher.

1. Can Handle Your Desired Materials

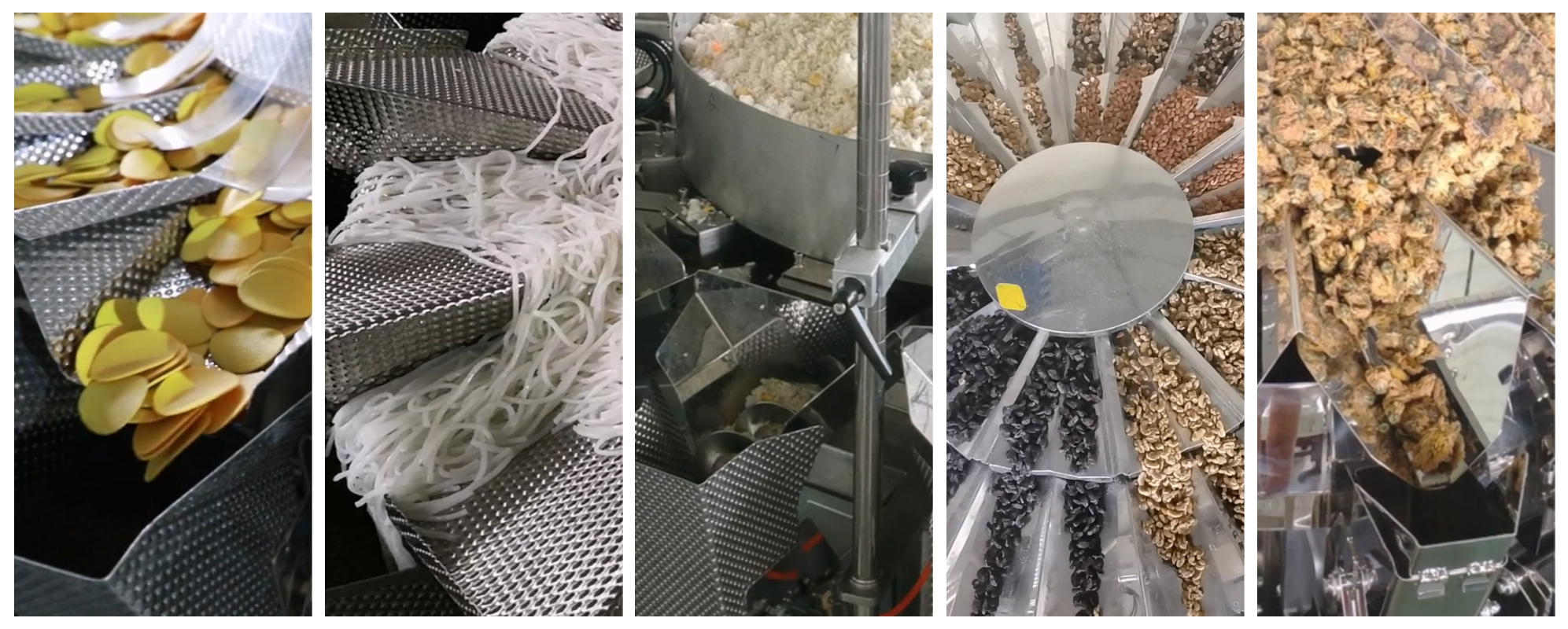

Factories process and package several different materials but every material aren't compatible with a multihead weigher.

While the machine is efficient enough to take up most of the food and non-food related products, there might be a slight chance that the product you want to package will not suit the dynamics of the machine you buy.

It is essential first to sit and curate a list of the products that will go into the weigher and then consult the materials with the multihead weigher manufacturers before investing in one.

2. Checks the Needed Accuracy

The next step should be to consider the accuracy before installing a multihead weigher packing machine if you do not want it to be a problem afterward.

The main goal for any company when buying this multihead weigher packing machine is to ensure its efficient and accurate weighing. Every multihead weigher offers a different accuracy which depends on its load cell value.

Therefore, before installing, one must ensure their desired accuracy level and whether the load cell value of the machine you choose can deliver it.

3. Provides Easy Cleaning and Maintenance

Another essential aspect to consider when installing and using a multihead weigher is ensuring that cleaning and maintaining it is easy.

If the machinery is in charge of mixing and packaging a variety of different materials, and hence cleaning the machine before loading a new batch is essential to avoid cross-contamination and deliver hygienic and safe products.

To check if your weigher holds the easy-to-clean technology, one should look into features like the IP rating of the machinery, along with bucket shape and removable parts.

4. Low on Energy Consumption

While lower energy consumption is an important aspect to consider for maintaining an eco-friendly approach, there is no denying that the rise in inflation is another reason which needs to be considered.

The multihead weigher packing machine can combine various types of weighers, and can pack a wide variety of products, providing low energy consumption values to help you save service costs while maintaining an eco-friendly environment.

5. Durability

When putting a hefty amount of money on the table, consumers must ensure that the machine they invest in is durable and will last them a long time.

It can be a massive problem if, before installation, one doesn't understand the warranty time and other dynamics that ensure your machine lasts you a long time.

Therefore focusing on the warranty while purchasing and ensuring that it is maintained efficiently is essential for your machine to last a long time.

At present, there are two types of multihead weigher packing machine at home and abroad. One is a multihead combination weigher. The other is a multi unit weigher. The latter can weigh different loads through multiple weighing heads, each weighing hopper discharging material to the same loading device, but this type of weigher lacks a combination function. Users should distinguish between them when choosing a multihead weigher. Otherwise it will be very difficult. Difficult to meet usage requirements. Multihead combination weigher is mainly used for high-speed and high-precision automatic quantitative weighing of uniform and non-uniform particles, regular and irregular bulk goods. The first is bulky and light, the second is easy to apply. Poor liquidity. The third category is foods that are difficult to separate. The fourth category is perishable packaged foods. The fifth category is frozen packaged food. The sixth category is packaged food leakage. The seventh category is dried and fresh fruits and local specialties.

Where Can You Buy the Best Multihead Weigher?

Now that you know all factors you should consider before installing and using this combination weigher for it not to become a problem, the next step is purchasing the said machinery. Finding a high-quality multihead weigher packing machine which isn’t only exceptional in working, but benefits you in many other regards too is not easy.

If you are someone who is searching for a high-quality and durable machine that doesn't cause many problems, we suggest you give Smart Weight a try.

The company is the best in business for providing high-quality factory machinery, and we are sure you won't be disappointed with its services.

Conclusion

We hope this article was sufficient to help you understand all factors that can become a problem if not considered before buying a multihead weigher.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved