Why Choose Smart Weigh's Vertical Packing Machine?

When your packaging line goes down, every minute costs money. Production stops, workers stand idle, and delivery schedules slip away. Yet many manufacturers still choose VFFS (Vertical Form Fill Seal) systems based solely on initial price, only to discover hidden costs that multiply over time. Smart Weigh's approach eliminates these painful surprises through comprehensive turnkey solutions that have kept production lines running smoothly since 2011.

What Makes Smart Weigh VFFS Machines Different?

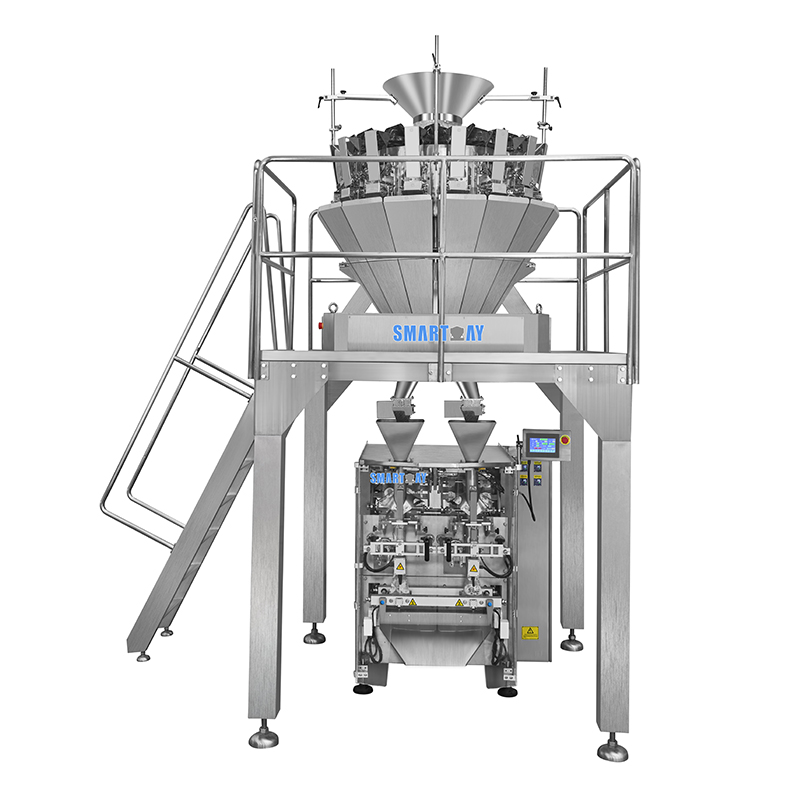

Smart Weigh delivers complete turnkey solutions with 90% integrated systems, factory-tested before shipping with customer materials, premium components (Panasonic PLC, Siemens, Festo), an 11-person expert service team with English support, and 25+ years of proven sealing technology.

Unlike typical suppliers who manufacture single components and leave integration to chance, Smart Weigh specializes in complete packaging line solutions. This fundamental difference shapes every aspect of their operation, from initial system design through long-term support.

The company's turnkey approach stems from practical experience. When 90% of your business involves complete packaging systems, you quickly learn what works—and what doesn't. This experience translates into well-planned system layouts, seamless component integration, effective cooperation protocols, and custom ODM programs for special projects.

Smart Weigh's programming capabilities set another key differentiator. Their in-house program makers develop flexible software for all machines, including DIY program pages that allow customers to make future modifications independently. Need to adjust parameters for a new product? Simply open the program page, make small changes, and the system accommodates your new requirements without calling for service.

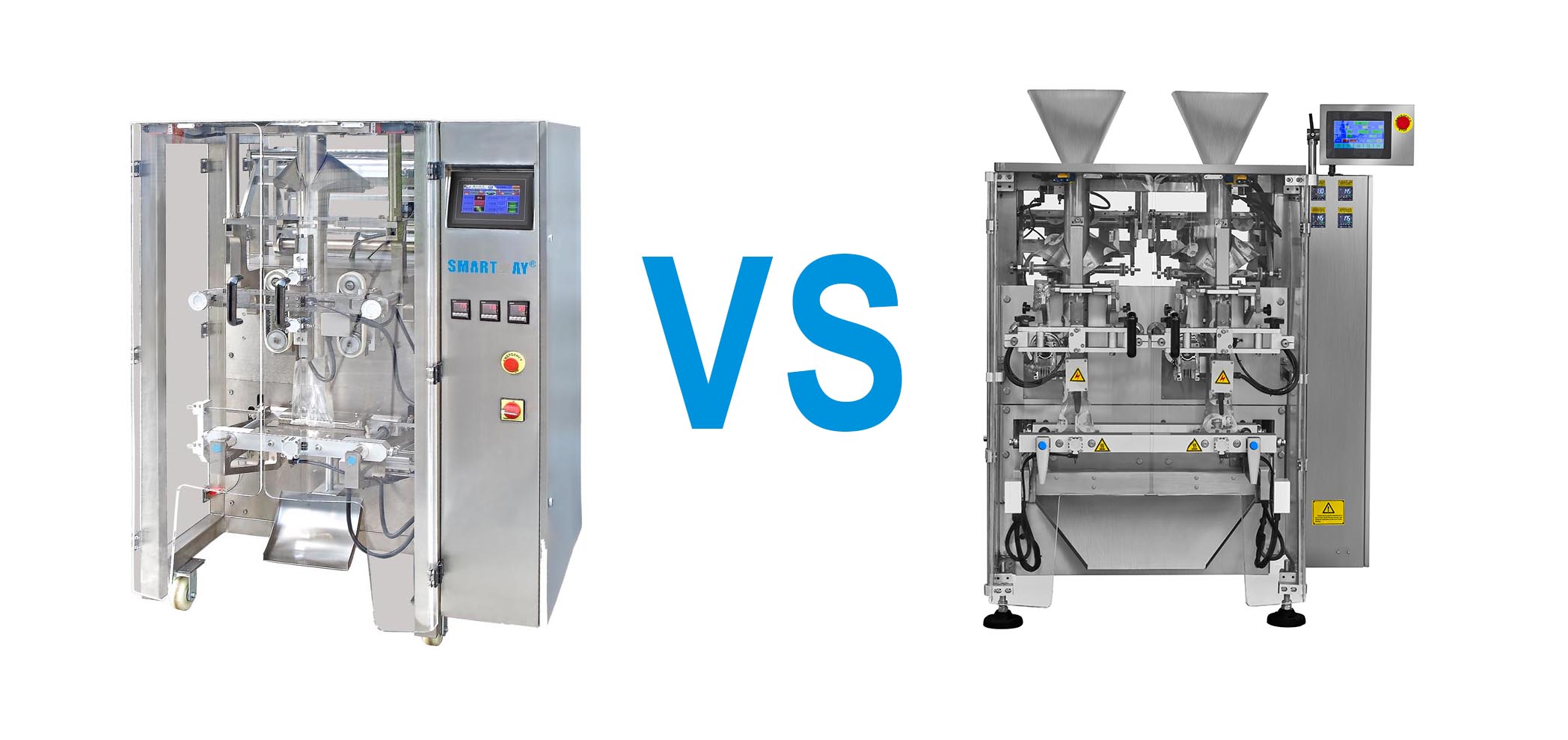

Smart Weigh vs Competitors: Complete Comparison

The packaging machinery industry operates on two distinct models, and understanding this difference explains why so many production managers face unexpected integration problems.

Traditional Supplier Model: Most companies manufacture one type of equipment—perhaps just the VFFS machine or only the multihead weigher. To provide complete systems, they partner with other manufacturers. Each partner ships their equipment directly to the customer's facility, where local technicians attempt integration. This approach maximizes each supplier's profit margins while minimizing their responsibility for system performance.

Smart Weigh Integrated Model: Smart Weigh manufactures and integrates complete systems. Every component—multihead weighers, VFFS machines, conveyors, platforms, and controls—comes from their facility as a tested, coordinated system.

Here's what this difference means practically:

| Smart Weigh Approach | Traditional Multi-Supplier |

| ✅ Complete factory testing with customer materials | ❌ Components shipped separately, untested together |

| ✅ Single-source accountability for entire system | ❌ Multiple suppliers, unclear responsibility |

| ✅ Custom programming for integrated operation | ❌ Limited modification options, compatibility issues |

| ✅ 8-person testing team validates performance | ❌ Customer becomes integration tester |

| ✅ Video documentation before shipment | ❌ Hope everything works upon arrival |

The quality difference extends to components themselves. Smart Weigh uses Panasonic PLCs, which offer reliable programming and easy software downloads from the manufacturer's website. Many competitors use Chinese versions of Siemens PLCs, making program modifications difficult and technical support complicated.

How Does Smart Weigh Prevent Common VFFS Problems?

Problem: Equipment Compatibility Issues

Picture this scenario: Your new packaging line arrives from multiple suppliers. The weigher dimensions don't match the VFFS machine platform. The control systems use different communication protocols. The conveyor height creates product spillage issues. Each supplier points to the others, and your production schedule suffers while technicians improvise solutions.

Smart Weigh Solution: Complete system integration testing eliminates these surprises. Their 8-person dedicated testing team assembles every packaging system in their facility before shipment. This team handles quality control from initial layout through final programming validation.

The testing process uses real-world conditions. Smart Weigh purchases roll film (or uses customer-provided materials) and runs the same or similar products that customers will package. They match target weights, bag sizes, bag shapes, and operational parameters. Every project receives video documentation or video calls for customers who cannot visit the facility personally. Nothing ships until the customer approves system performance.

This thorough testing reveals and resolves issues that would otherwise surface during commissioning—when downtime costs are highest and pressure is greatest.

Problem: Limited Technical Support

Many packaging equipment suppliers provide minimal ongoing support. Their business model focuses on equipment sales rather than long-term partnerships. When problems arise, customers face language barriers, limited technical knowledge, or finger-pointing between multiple suppliers.

Smart Weigh Solution: An 11-person expert service team provides comprehensive technical support throughout the equipment lifecycle. These specialists understand complete packaging systems, not just individual components. Their turnkey solution experience enables them to diagnose and resolve integration issues quickly.

Importantly, Smart Weigh's service team communicates effectively in English, eliminating language barriers that complicate technical discussions. They offer remote programming support through TeamViewer, allowing real-time problem solving and software updates without site visits.

The company also maintains comprehensive spare parts inventory with a lifetime availability guarantee. Whether your machine was purchased recently or years ago, Smart Weigh stocks necessary components for repairs and upgrades.

Problem: Difficult Programming and Modifications

Production requirements change. New products require different parameters. Seasonal variations demand operational adjustments. Yet many VFFS systems require expensive service calls or hardware changes for simple modifications.

Smart Weigh Solution: User-friendly programming interfaces enable customer-controlled adjustments. The system includes built-in know-how pages that explain every parameter and acceptable value ranges. First-time operators can reference these guides to understand system operation without extensive training.

For routine modifications, Smart Weigh provides DIY program pages where customers make adjustments independently. More complex changes receive remote support through TeamViewer, where Smart Weigh technicians can install new programs or add customer-specific functions.

What Are Smart Weigh VFFS Key Features?

Advanced Electrical System

Smart Weigh's electrical design philosophy prioritizes reliability and flexibility. The Panasonic PLC foundation provides stable, programmable control with easily accessible software support. Unlike systems using generic or modified PLCs, Panasonic components offer straightforward programming modifications and reliable long-term operation.

The stagger dump feature demonstrates Smart Weigh's practical engineering approach. When the multihead weigher runs low on material, traditional systems continue operating, creating partially filled or empty bags that waste materials and disrupt packaging quality. Smart Weigh's intelligent system automatically pauses the VFFS machine when the weigher lacks sufficient material. Once the weigher refills and dumps product, the VFFS machine automatically resumes operation. This coordination saves bag material while preventing damage to sealing mechanisms.

Automatic bag detection prevents another common waste source. If a bag doesn't open correctly, the system won't dispense product. Instead, the defective bag drops onto the collection table without wasting product or contaminating the sealing area.

The interchangeable board design provides exceptional maintenance flexibility. Main boards and drive boards interchange between 10, 14, 16, 20, and 24-head weighers. This compatibility reduces spare parts inventory requirements and simplifies maintenance procedures across different production lines.

Superior Mechanical Design

Smart Weigh's mechanical engineering reflects international manufacturing standards. The complete system uses 304 stainless steel construction, meeting EU and US food safety requirements. This material choice ensures durability, hygiene, and corrosion resistance in demanding production environments.

Laser-cut component manufacturing provides superior precision compared to traditional wire cutting methods. The 3mm frame thickness offers structural stability while maintaining clean, professional appearance. This manufacturing approach reduces assembly errors and improves overall system quality.

The sealing system optimization represents 25+ years of continuous refinement. Smart Weigh has systematically modified sealing rod angles, pitch, shape, and spacing to achieve optimal performance across various film types and thicknesses. This engineering attention prevents air leaks, extends food storage life, and maintains seal integrity even when packaging film quality varies.

Larger hopper capacity (880×880×1120mm) reduces refilling frequency and maintains consistent product flow. The vibration-independent control system allows precise adjustment for different product characteristics without affecting other operational parameters.

What Do Smart Weigh Customers Say?

Long-term performance provides the ultimate validation of equipment quality. Smart Weigh's first customer installation from 2011—a 14-head system packaging bird seed—continues operating reliably after 13 years. This track record demonstrates the durability and reliability that customers experience with Smart Weigh systems.

Customer testimonials consistently highlight several key benefits:

Reduced Material Waste: Intelligent system controls minimize product giveaway and prevent bag waste, directly impacting profitability on high-volume production lines.

Decreased Downtime: Quality components and comprehensive testing reduce unexpected failures and maintenance requirements.

Easier Maintenance: Interchangeable components and comprehensive technical support simplify ongoing maintenance procedures.

Better Seal Quality: Optimized sealing systems provide consistent, reliable packaging that preserves product quality and extends shelf life.

These benefits compound over time, creating substantial value beyond the initial equipment investment.

How Much Does Smart Weigh VFFS Cost vs Value?

Total Cost of Ownership Analysis

Initial purchase price represents only a fraction of packaging equipment costs over its operational lifetime. Smart Weigh's integrated approach addresses the hidden costs that often multiply with traditional multi-supplier systems.

Hidden Competitor Costs:

Integration delays extending project timelines

Multiple supplier coordination consuming management time

Compatibility problems requiring custom modifications

Limited technical support creating extended downtime

Inferior component quality increasing replacement costs

Smart Weigh Value Proposition:

Single-source accountability eliminating coordination overhead

Pre-tested integration preventing startup delays

Premium component reliability reducing maintenance costs

Comprehensive support minimizing operational disruptions

Is Smart Weigh VFFS Right for Your Application?

Ideal Applications

Smart Weigh systems excel in demanding production environments where reliability, flexibility, and food safety compliance are paramount. Typical applications include:

Food Packaging: Snacks, frozen foods, powders, granular products requiring precise portioning and reliable sealing

Pet Food and Bird Seed: High-volume applications where dust control and accurate weighing are critical

Agricultural Products: Seeds, fertilizers, and other granular materials requiring weather-resistant packaging

Specialty Products: Items requiring custom programming or unique packaging configurations

Key Decision Criteria

Production Volume: Smart Weigh systems are optimized for medium to high-volume operations where equipment reliability directly impacts profitability.

Product Characteristics: The flexible programming and vibration control make these systems excellent for challenging products including sticky, dusty, or fragile materials.

Quality Requirements: Food safety compliance, consistent portioning, and reliable sealing make Smart Weigh ideal for regulated industries.

Support Expectations: Companies wanting comprehensive technical support and long-term partnerships find exceptional value in Smart Weigh's service model.

How to Get Started with Smart Weigh VFFS

Evaluation Process

Application Assessment: Smart Weigh's technical team evaluates your specific product characteristics, production requirements, and facility constraints to design optimal system configurations.

System Design: Custom engineering ensures that every component—from multihead weighers through VFFS machines to conveyors and platforms—integrates seamlessly for your application.

Factory Testing: Before shipment, your complete system runs with your actual materials under production conditions. This testing validates performance and identifies any necessary adjustments.

Installation Support: Smart Weigh provides complete commissioning assistance, operator training, and ongoing technical support to ensure smooth startup and reliable operation.

Next Steps

Choosing packaging equipment represents a significant investment in your company's future. Smart Weigh's comprehensive approach eliminates the risks and hidden costs associated with traditional suppliers while providing superior long-term value.

Contact Smart Weigh's technical team to discuss your specific packaging requirements. Their turnkey solution experience and commitment to customer success will help you avoid the common pitfalls that plague packaging line installations while ensuring reliable, profitable operation for years to come.

The difference between Smart Weigh and traditional suppliers becomes clear when production demands peak performance: one provides complete solutions backed by comprehensive support, while the other leaves you managing multiple relationships and solving integration problems independently. Choose the partner that eliminates surprises and delivers results.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine