Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

In fast-paced realm of packaging of the produce, it is essential that the efficiency comes in place to preserve the quality of the product, for prolonged shelf life and to meet consumer expectations. The packaging machines are crucial in modern operations, along the way, they let you realize things with ease and enhance the general productiveness. This article is about several kinds of produce packaging equipment and the aspects they use, the benefits these have and of course the things to watch.

Effective packaging serves multiple functions beyond mere containment:

✔Protection: Packaging functions as a protection measure by preventing products from both physical and chemical damage, contamination, and moisture loss, hence, ensuring product integrity during transport and storage.

✔Preservation: With good packages that regulate the various factors like temperature, humidity, air exposure, and light, fresh vegetable can have their shelf-life extended.

✔Convenience: Well-designed placed product is lighter in weight, therefore it can be held, moved, and stored easily leading to less which makes logistics and operation so smooth.

✔Marketing: Consumers make impulsive food choices based on the look of the outer packaging on the shelf without reading the crucial nutritional information. Packaging plays the role of a powerful marketing instrument that gives a brand its identity and provides the product info to the customers.

Produce packing equipments are designed to process products like fruits, leafy vegetables, root vegetables and other agricultural. The option of the machine depends on the aspects, such as product category, volume in use, package materials, and the desired capacity. Common types of produce packaging machine include:

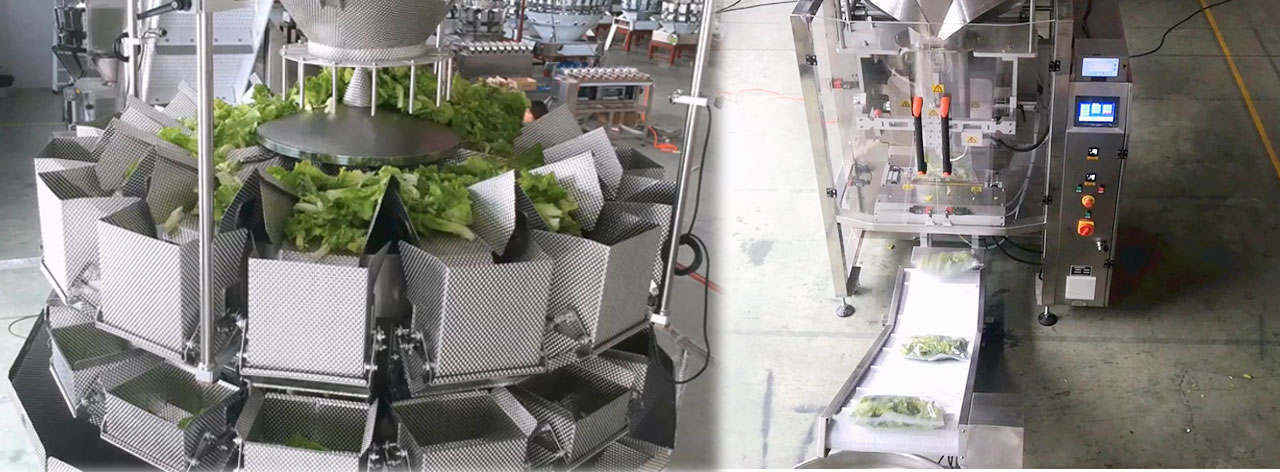

It this equipment comes in staggering they precisely weigh and measure a number of fresh vegetables into individual bags. The owners of the farm usually are equipped with the multi-head weighting system, which is gentle and delicate to the product, checking the product before dispensing it correctly to the bags. In this way, package weights are uniform and thus invariable.

VFFS machines are among the main actors in the manufacturing industry bringing speed to operations. The vertical form fill seal machine utilizes holding support to maintain the plastic film in an upright position. After positioning the film, the produce examples include spinach leaves or bean sprouts—is weighed and filled. Subsequent to filling, the machine seals the package with top and bottom sealing mechanisms. These devices are compact and reusable, being a perfect choice in terms of moving different bag sizes, and properly closing the loose produce items flowing through them.

The individual packs with 'name your own' fruits and vegetables are processed by this corrugated clamshell-type machines. As another instance, packaging clamshells which are clear containers that saves the savory berries or grape tomatoes fragility. Following the firm procedures, they prepare the food by putting them into containers where they keep them under specific temperature and can close them if necessary. Shell layout permits person to check out a product without been hindered and this is on the other hand can create a good arrangement in the shop.

Wrap up the produce in a pillow bag, the result is a slimy but protective grid across the product. Packaging of this class is suitable for delicate focus on good stuff like bell peppers or cucumbers hence product integrity as well as presentation is guaranteed.

Tray sealers are multifunctional equipment with cutting capability in addition to sealing trays of sliced fruits, salads, and other produce for packaging. In most cases the operators use a film cover tightly spread over the tray and also seal it. The atmospheric conditions are often modified to extend the freshness. P-seal packaging for fresh produce is the one giving it shelf appeal as well as trouble-free stacking and display.

The produce shrinks wrap machines work by applying heat to the film, thus tightly wrapping the produce in the layer of the film and creating a snug and protective covering. This packaging approach is widely adopted where items like packs of herbs or kale bundles are secured together in this way, yielding a neat and secure packaging.

In contrast to netting machines, protective nets are breathable and are used to bag products such as oranges, potatoes or onions. The net bags enable both checking of the quality of the veggie while at the same time keeping them safe and easy to move to somewhere else.

Packaging bundle machines tend to be employed for grouping of single produce products together into packages. These are perfect for handling the products that are usually better off as a fixed unit, like for instance bunches of asparaguses or herbs. In addition, machines that isolate the items together guarantee that they remain together during the production and when being displayed.

Smart Weigh provides a totally integrated packaging facility covering the functions ranging from automatic weighing, packaging, cartooning, printing, labeling, and palletizing. This creates default to smooth running activity and the process resulting in efficiency. With over 12 years’ experience, Smart Weigh has deep understanding for the market so you always get a well-thought-out packaging solution.

●Increased Efficiency: Automation is driving manual labor out of the picture, it is increasing speed of packaging, and finishing products faster.

●Improved Product Quality: The tightness of the weighing, processing, and sealing is what ensures the freshness and perception of the product.

●Enhanced Food Safety: Safety elements put in place prevent the resurgence of bacterial communities while the food safety regulations are fulfilled satisfactorily.

●Cost Savings: The biggest drawback of automation is its initial investment cost but efficiency, productivity and quality of the final products more than compensates that through reduced labor, minimizing wastage and increasing productivity in the long run.

Key factors to consider when selecting a produce packing machine include:

√Product Type and Characteristics: The machines should be chosen not also according a number of parameters, such as the size, shape or fragility of the produce.

√Packaging Material Compatibility: Let the device promote correct types of packaging material.

√Throughput and Capacity: Pick up a machine of the types that produce products in large volumes easily.

√Automation Level: Determines the best automation level considering the available workforce capacity and the budget prerequisites.

√Maintenance and Support: Go for machines on the market with renowned producers who offer proper maintenance agreements as well as technical assistance.

Although we have heard much about the future of produce packaging technologies, many are still unsure about just how they will impact the industry.

◆Smart Packaging: Tracking product quality during transportation, that is IoT application use.

◆Robotics and AI: Integration of bots sorting select and package the produce with much more precise and efficiency.

◆Sustainable Packaging: Seconding eco-friendly and recyclable materials to lower the environmental print.

Packaging machines, especially the one destined to process fruits and vegetables, are known for their perfectionism, that is portrayed through uniformity, accuracy, and quality all the time. It's essential to choose a machine that suits industry needs when precisely these three points - efficiency, lowering of labor costs and the race to gain and remain competitive. Buying New Smarter Packaging can demonstrate that you are an innovative and successful leader in the produce packaging industry when you select from Smart Weigh’s comprehensive packaging solutions, which are backed by research and customer satisfaction.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved