Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

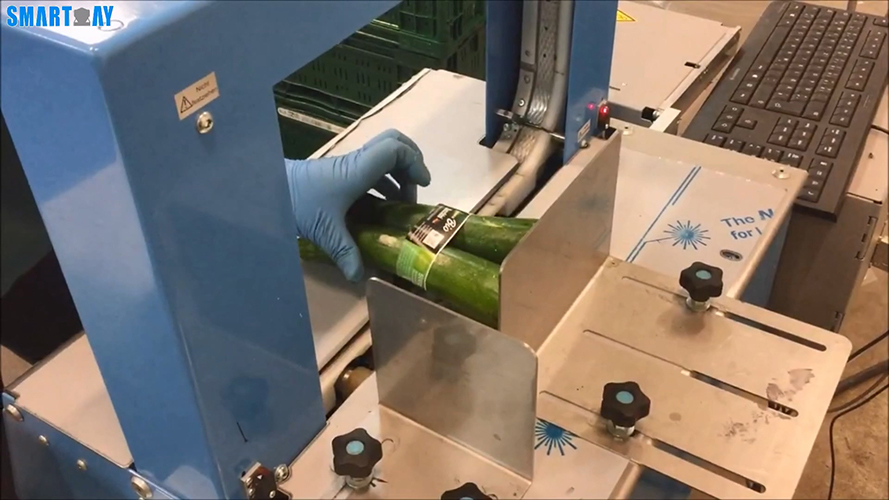

Vegetable packing machines have revolutionized farming technology. They alter the treatment of fresh food from the farm to the retailer. The sophisticated technology guarantees fast and accurate packing of vegetables to maintain their freshness and quality.

When the packing process is automated, these machines are more efficient, waste is lessened, and all packages are packed consistently. Packaging equipment is crucial for maintaining the nutritional worth and attraction of fresh food.

Farmers and producers cannot operate today without vegetable packing equipment since better cleanliness and efficiency standards are in demand. So, let's explore these packaging machines in more detail here!

Vegetables should be packed in many stages to maintain their freshness and safety. First, they are selected and cleaned to eliminate trash or dirt. Then, they are grouped according to size and quality.

Following their sorting, the veggies are precisely weighed and split into quantities fit for storage. By closing the packages, they will survive longer and avoid being subject to environmental elements that might compromise their quality.

The kind of vegetable and its requirements decide the packaging material used. Polypropylene (PP) films are excellent at keeping water out; polyethylene (PE) bags are light and flexible. For delicate or precious vegetables, clamshell containers and vacuum-sealed bags work wonderfully.

They last longer since they keep the vegetables fresh and shield them from injury. Keeping the freshness and quality of vegetables along the supply chain depends on these factors, which also help to ensure that they reach consumers in the best possible condition.

Automated vegetable packaging tools have many benefits, making farming more efficient, safer, and more effective at producing quality food. Here are some main reasons why these tools are so important in modern farming.

Perfect control over the packing process made possible by vegetable packaging machines guarantees that every product satisfies high requirements. Automated methods reduce human error by utilizing consistent, dependable results that maintain the high quality of the goods.

These machines provide consistency in packaging, thus lowering the possibility of under or over-filling, influencing the integrity of the product. A regulated climate also helps them keep the freshness and nutritional worth of the vegetables, guaranteeing that buyers always get premium products.

These machines make production go much faster by automating the packing process. They can quickly and easily handle a lot of veggies, which helps meet high demand and shortens the time it takes to get vegetables from the field to the market.

These equipments greatly boost throughput by simplifying the packing process, enabling producers and farmers to match market needs. Furthermore, the higher efficiency guarantees fresh food gets to consumers when it is still at its best, minimizing delays and congestion.

Automated packing greatly reduces the possibility of product rejection by guaranteeing that every box is uniform and properly packed. This consistency preserves the vegetables' look and quality, lowering waste and raising consumer satisfaction.

Automated systems guarantee that every shipment meets high-quality criteria by reducing mistakes, including wrong weights or inadequate sealing. This increases the supply chain's general effectiveness, consumer confidence, and dependability since consumers know they will always get premium goods.

Vegetable packing instruments Maintaining a clean packing area helps to stop food contamination. By sealing the packaging, dirt, bacteria, and other dangerous elements are kept out of the vegetables to remain safe for consumption.

These machines produce a regulated atmosphere that reduces the possibility of outside pollutants, maintaining produce hygiene and safety. This degree of protection depends on maintaining fresh veggies' integrity and health advantages, giving consumers safe, premium products.

Vegetables kept properly wrapped against air, light, and moisture last longer. This longer shelf life guarantees more produce reaches consumers in ideal condition, helping lower waste and spoilage.

The packaging serves as a barrier against elements in the surroundings that could hasten nutritional loss and degradation. These devices enable stores and farmers to reduce losses and optimize the value given to consumers by keeping the freshness and quality of the veggies for a longer period, thus supporting sustainability in the supply chain.

By controlling the surroundings, vegetable packing equipment helps maintain the food's freshness and nutritional value. These machines guarantee that the vegetables keep their great taste, suitable texture, and health advantages by maintaining ideal conditions.

It is essential to provide excellent cuisine that satisfies customer expectations. Exact control over temperature, humidity, and other variables avoids nutrient degradation and spoiling, enabling consumers to enjoy fresh, wholesome vegetables that support a good diet.

Automation greatly lessens the requirement for human labor in the packing process, thereby saving a lot of expenses. By relying less on hand labor, farms, and producers can better allocate their resources and invest in other spheres of their companies.

It raises general efficiency and allows labor to be reallocated to other important chores, improving output. Furthermore, the lower operating expenses resulting from decreased personnel costs offer a competitive advantage and help the agricultural company be sustainable and expandable.

Vegetable packaging equipments need little operator involvement and are made to be easy to operate. This simplicity of use guarantees flawless running of the packing process free from interruptions and lowers the possibility of mistakes.

Often, with self-monitoring capabilities that notify operators of any problems, automated systems are user-friendly and help minimize the necessity of continuous control. These machines improve production and dependability by streamlining the procedure, freeing staff members to concentrate on other crucial chores while preserving a constant and effective packing technique.

Automated machines guarantee that every package satisfies the requirements by producing consistent and reliable results. Customers and stores, who can rely on the quality of the produce, will develop trust in this dependability.

The homogeneity attained results in every package looking and feeling the same using automation, minimizing variances that can cause customer discontent. These machines guarantee that clients get the greatest possible production every time by regularly producing excellent products, strengthening brand reputation and loyalty.

Correctly packaged vegetables are safer during storage and transportation. Packaging equipment helps lower the danger of damage and spoilage on the route by guaranteeing the fruit is cushioned and properly covered.

These machines help preserve the veggies' integrity and freshness throughout the supply chain by acting as a barrier. This safe packing guarantees that buyers get premium goods that have been securely transported and kept, reducing losses resulting from handling and environmental conditions.

Smart Weigh offers various tools for packing vegetables. Each one has different features to meet different packing needs. Here are some of the best things about their creative ideas.

Smart Weigh's Veggies Pillow Bag Packing Machine is an efficient and flexible way to package different veggies. This machine works with different types and sizes of bags, making the packing process flexible and adaptable.

It allows flawless integration into many manufacturing environments and precisely and dependably meets different packaging needs. The capacity to effectively manage several bag forms improves output and guarantees that vegetables are packed securely and quickly, satisfying contemporary agricultural activities' needs.

Smart Weigh's Salad Container Filling Machine is perfect for precisely packaging fresh salads. This machine guarantees the exact filling and sealing of containers, preserving the freshness and excellent quality of the salads and reducing the possibility of waste and contamination.

Its sophisticated filling technologies and sealing systems provide consistent portioning and strong sealing, improving food safety and shelf life. Designed to satisfy strict hygienic standards, the Salad Container Filling Machine is a dependable tool for ensuring salads arrive at consumers in the best shape.

The Cherry Tomato Clamshell Packing Machine was particularly developed to handle delicate foods like cherry tomatoes with great care. This machine painstakingly compresses the tomatoes into clamshell boxes, keeping them secure from harm during handling and shipping.

The machine increases cherry tomato shelf life through a protected container, maintaining freshness and quality. This specialist packaging solution improves product safety and appearance, reduces waste, and is essential for preserving the integrity of fragile products.

Smart Weigh's veggies Weighing and Bunching machines accurately weigh and bundle veggies so that portions are always the same. Maintaining great quality and regularly meeting market criteria depend on this accuracy. These machines simplify operations and lower variation in product presentation by automating the weighing and packing processes.

They help growers and manufacturers maximize efficiency and reduce waste while delivering consistent vegetable quantities that satisfy consumer expectations. Constantly providing homogeneous vegetable bundles improves dependability and customer happiness, promoting general agriculture company performance.

Modern farming can't be done without vegetable packaging tools, which offer many benefits. Automating the packing process makes these tools more efficient, reduces waste, and ensures that all packages are identical. They keep vegetables clean and safe during storage and travel by keeping them from getting dirty or damaged.

Smart Weigh's range of packaging tools, such as those that fill salad containers, pack cherry tomatoes in clamshells and weigh and bunch vegetables, show how advanced fresh produce packaging solutions can be. As standards for cleanliness and efficiency rise, farmers and producers can't do their jobs without these machines.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved