Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Long shelf life and quality preservation for dry fruits depend on effective packaging. The leading producer in the packaging sector, Smart Weigh provides innovative vertical packing machines catered to the greatest degrees of accuracy and efficiency.

Their creative ideas, including the Twin Tube Double Lines Vertical Packing Machine and the Smart Weigh Pouch Packing Machine, are meant to increase output and guarantee the best packing results.

Investing in Smart Weigh's modern dried fruit packaging machine will help companies achieve exceptional packaging performance, ensuring their dried fruits stay appealing to customers.

Dry fruit packing machines come in various styles, such as vertical and bag packing machines. Let's learn about them both in detail here:

Due to their adaptability and efficiency, vertical packing machines are indispensable in the packaging business. These upright-oriented, shape, fill, and seal machines are ideal for various dry fruits, including almonds, cashews, raisins, and more.

These machines are meant to be used straightforwardly. Vertical packing systems are particularly preferred for their capacity to handle big numbers and offer exact packaging.

High-speed operation, adaptability, accuracy, user-friendly interface, and strong construction define Dry Fruits Vertical Packaging Machines.

✔ High-Speed Operation: High-demand workplaces would find vertical packing machines perfect since they can pack many products per minute.

✔ Versatility: These devices provide manufacturers versatility by allowing the handling of many packaging materials and sizes.

✔ Accuracy: With sophisticated weighing systems and vertical packing devices, which guarantee exact filling and reduce product waste.

✔ User-Friendly Interface: Modern vertical packaging machines optimize operation and maintenance by including simple-to-navigate controls and touch screens.

✔Durability: These machines are built with premium components to resist the stresses of constant running.

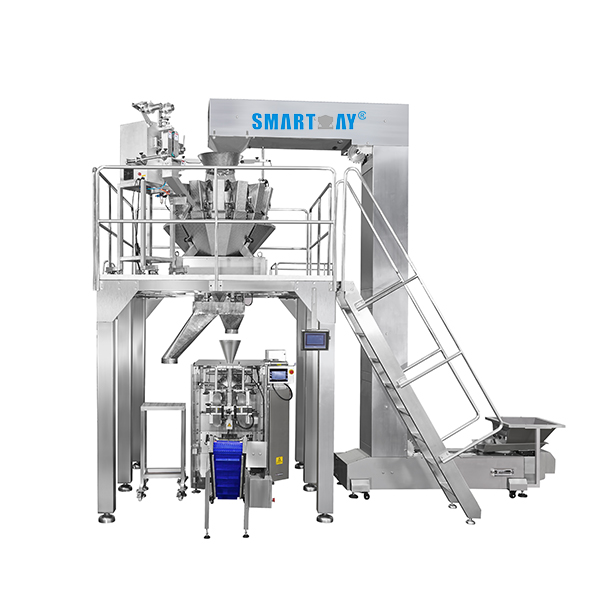

One well-known producer with excellent packaging solutions is Smart Weigh. Their vertical packaging equipment is made to satisfy the best criteria of accuracy and efficiency. These two are among their best models:

Large-scale packing operations would find the high-precision, high-speed SW-P420 machine with 10 head or 14 head weigher, perfect for them. Advanced weighing technology guarantees accurate and effective packing. Important elements consist of the following:

▶High-Speed Operation: capable of packing up to sixty bags every minute.

▶ Advanced Weighing Technology: guarantees exact filling, therefore minimizing product waste.

▶ User-Friendly Interface: it has a simple touch screen for operation.

▶Durable Construction: Made of stainless steel, it guarantees lifetime and corrosion resistance.

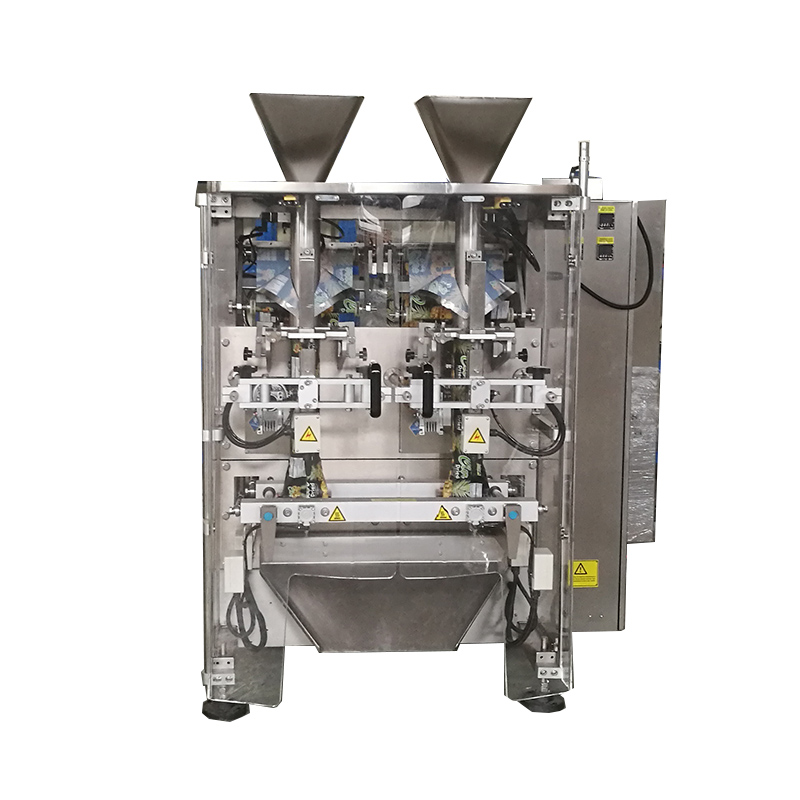

It is designed for larger production, and this machine has twin tubes, enabling double-line packaging. Works with twin discharge 20 head or 24 head weigher, It's ideal for companies trying to maximize output effectiveness. Important qualities include:

●Double-Line Packaging: Simultaneous two-line packaging increases production capacity.

●High Precision: Modern systems of weighing and filling guarantee accuracy.

●Robust Design: Designed to run nonstop in tough environments

●Ease of Use: equipped with a simple control panel for maintenance and operation.

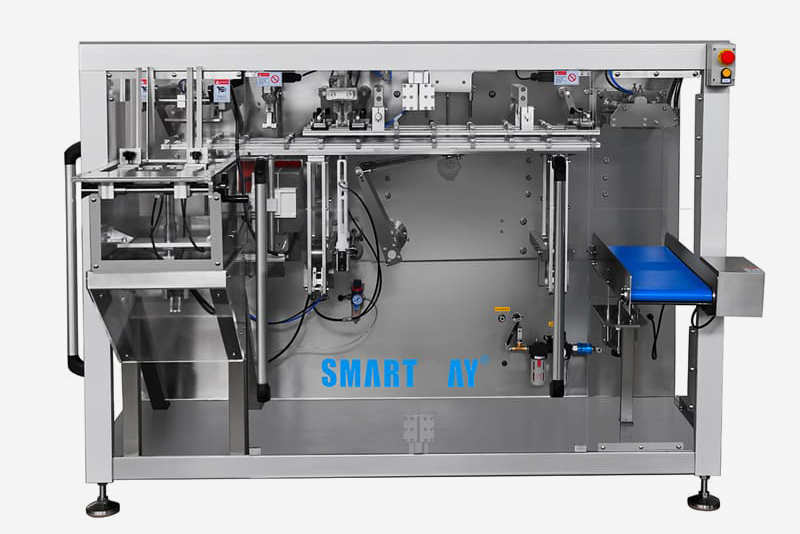

Packaging dried fruits into several pouches, such as stand-up and zipper pouches, requires "dry fruit pouch packing machines." These flexible machines are perfect for small—and large-scale enterprises because they handle several pouch forms and sizes.

The strong and consistent seals they provide help maintain product freshness and prevent contamination. Many pouch packaging machines improve their output through automated filling, sealing, and labeling. These small-footprint machines are ideal for companies with limited space.

They also offer adaptability, managing various goods, including snacks and other foods. Several pouch-packing machines are available, including rotary, horizontal, vacuum, and small pouch-packing machines; each has special qualities to meet various packing requirements.

Dry Fruits Pouch Packing Machines have many useful features, such as being flexible, sealing well, being automated, being small, and handling different goods and pouch types.

▲Flexibility: These machines fit different packaging requirements since they can handle several sizes of bags.

▲Sealing Efficiency: The strong and dependable sealing made possible by pouch packaging machines helps maintain product freshness and prevent contamination.

▲ Automation: Many pouch packaging machines have sophisticated capabilities, such as automatic filling, sealing, and labeling, improving output.

▲ Small Design: Ideal for companies with limited space, these machines are made to occupy as little floor area as possible while nevertheless providing great efficiency.

▲Versatility: managing various food products, including dry fruits, snacks, and other foods.

There are different types of Dry fruit pouch packing machines. Each machine's features are described below:

High-speed packaging is best suited for rotary pouch packing machines, allowing the handling of several pouch designs. Their effective filling and sealing of pouches comes from a revolving mechanism. Important characteristics are:

△High-Speed Operation: capable of packing about 40-80 pouches every minute.

△ Versatility: It can manage several types and sizes pouch, including zipper and stand-up pouches.

△ Precise Filling: Modern systems of weighing and filling ensure accuracy.

△User-Friendly Design: It is compact in size and easy to run and maintain.

Larger pouches and items must be laid flat to fit horizontal pouch-packing machines. They are renowned for their exact filling and sealing powers. Key characteristics include the following:

■ Versatility: Can manage a variety of pouch kinds and sizes.

■ High Precision: guarantees correct filling and sealing, reducing product waste.

■ Robust Construction: Designed for constant running.

■ Ease of Use: has an understandable control panel for maintenance and operation.

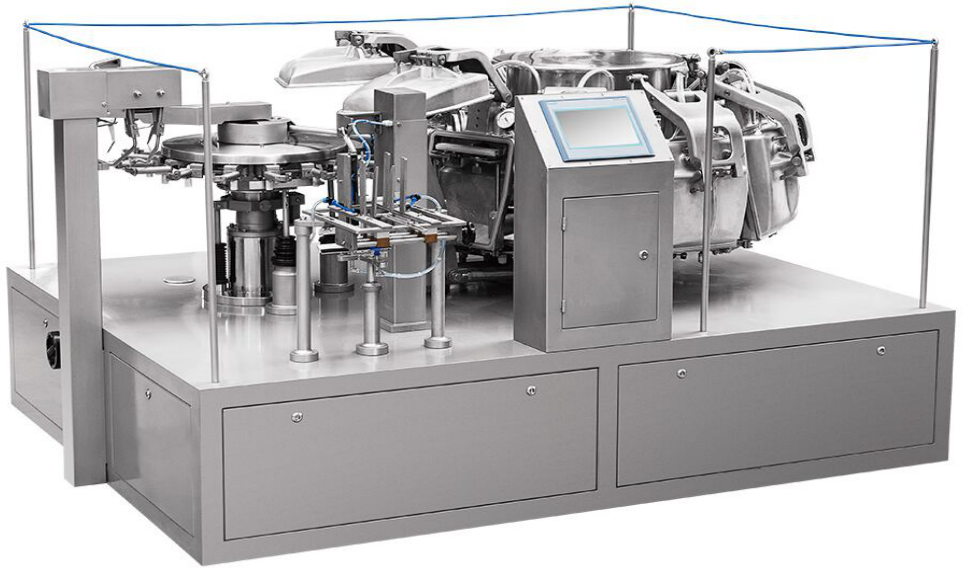

The extended shelf life of dry fruits depends on vacuum pouch packing machinery removing air from the package. These devices are ideal for maintaining the freshness and quality of the goods. The key components consist of the following:

★Extended Shelf Life: Vacuum packing removes air, preserving product freshness and quality.

★Versatility: can manage several pouch sizes and kinds.

★ High Precision: guarantees perfect sealing and vacuuming.

★ Durability: these machines are meant to last and are designed from premium materials.

Mini pouch packaging machines are meant for limited space companies or small-scale activities. They provide innovative packaging ideas without affecting quality. Important elements consist of the following:

◆ High Efficiency: able to package a respectable amount of goods.

◆ User-Friendly Interface: Simple for use and maintenance.

◆ Compact Design: Perfect for companies with limited areas.

◆ Cost-Effective: offers a cheap solution for small-scale packaging requirements.

The proper dry fruit packing machine is essential for effective, hygienic, and visually pleasing packaging. Large-scale operations with high-speed and precise needs call for vertical packing machines like Smart Weigh's SW-P420 and Twin Tube Double Lines.

Flexible solutions for several pouch kinds and sizes provided by pouch packaging machines guarantee long shelf life and product freshness. Invest in quality to improve the lifetime and appeal of your goods.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved