Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The multihead packing machine has brought significant improvement in the packaging industries. Businesses want accurate weighing and portioning of the products, which is offered by the multi head packing machine. As a result of this, the demand for multihead packing machine has been on a constant rise. Many businesses are benefiting significantly with the use of weigher packing machine. Among these includes – food, pharmaceutical, and consumer good companies.

In this article, we will discuss about multihead weigher packing machine. Additionally, we will also talk about its operations, advantages, and the products suitable for packaging.

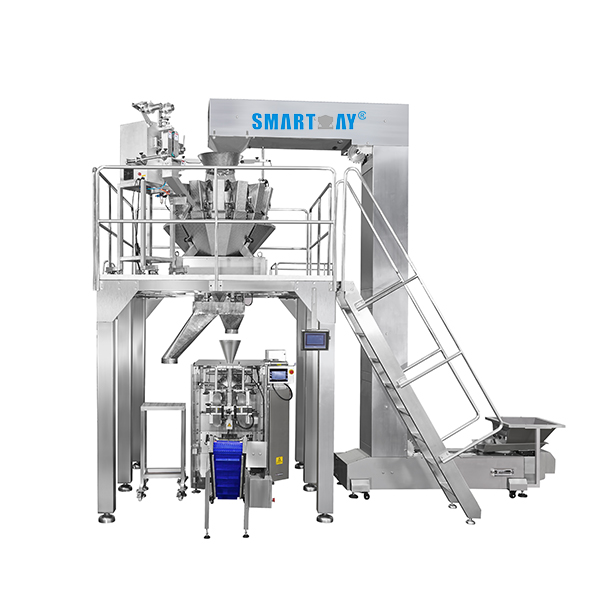

A multihead packaging machine is also known as multihead weigher packaging machine. The industrial machinery helps businesses to correctly weigh and dispense a range of products. Like discussed previously, the machine is widely used across sectors – including food, pharmaceutical, and consumer goods. Being said that, these are the businesses where efficient and precise packaging is needed.

Being said that, the machine consists of multiple weighing heads - ranging from 8 to 32. These heads are mounted on a central frame. There is a central vibrating top cone that distributes the products into individual hoppers. The weighing heads measure the weight of each smaller portion and then determines the best combination to achieve the targeted weight.

The product is transferred into the chosen packaging format and is either heat sealed or vacuum sealed to ensure product freshness. Being said that, different packaging format such as bags, jars, and pouches can be used for packing the products.

There are several key steps that are involved in the operations of the multihead of packing machine. Here is a detailed explanation step-by-step.

◆1. The initial step begins with the feeding of the product into the central dispersion system of the machine. The product is then evenly distributed across different weighing heads. The vibrating top cone ensures that the flow of the material is even.

◆2. After even distribution, each of the weighing heads calculates the product weight in their compartment. The continuous measures and records enable real-time calculation for accurate combination selection. This ensures minimal wastage.

◆3. After the determination of the right weight, the product is dispensed into the packaging system such as pouches, containers, or bags. To prevent any delays, the dispensing process is fast and synchronized.

◆4. The packing is sealed using one of the different methods including heat or vacuum sealing. Some systems also offer integrating labeling and printing of information such as expiry dates and batch numbers.

This machine pack products in bags using vertical form-fill-seal (VFFS) technology. Being said that, the process involves forming a bag from a film roll, filling it with the product, and then sealing it.

This machine is designed for filling and sealing pre-formed pouches. Being said that, the pre-made pouches are fed into the machine, opened, filled with the accurately weighed product, and then sealed using different techniques.

This machine is best suited for dispensing weighed portions into jars or rigid containers. It ensures precise weight distribution before sealing. Being said that, the machine is frequently used for food products such as nuts, candies, and powders.

The benefits of a weigher packing machine extends beyond speed and accuracy. Among the top advantages of multihead weigher packing machines includes the following:

The multi head packing machines have the capabilities to process large quantities of products at a higher rate. This, when compared to traditional weighing and packing machines, reduces time significantly for the business.

The modern weighing techniques ensures that there is minimal wastage, while also offering precise weights. As the machine selects the right combination of weights, it leads to better use of materials, offering cost savings to businesses in the long run.

The automation offered by the multi head filling machine ensures accuracy and consistency in the product packaging. This becomes all the more important for the businesses that are seeking uniform branding and customer satisfaction. It also allows them to meet the regulatory compliance.

The automation and reduction in wastage of materials leads to cost savings for businesses. Furthermore, the multihead packing machines also results into reduced labor cost. All of these savings’ offsets for the initial investment required for the purchase of the machinery.

Another benefit offered by the multihead packing machine is a food safe environment. Being said that, hygiene is the one of the most important things for businesses - especially in the food and pharmaceutical sector. The food grade components used in the machine ensures cleanliness and prevents contamination.

This packing machine offers your business with a versatile solution. It can be used for packaging of products across many industries. To name a few - food, pharmaceuticals, and consumer goods.

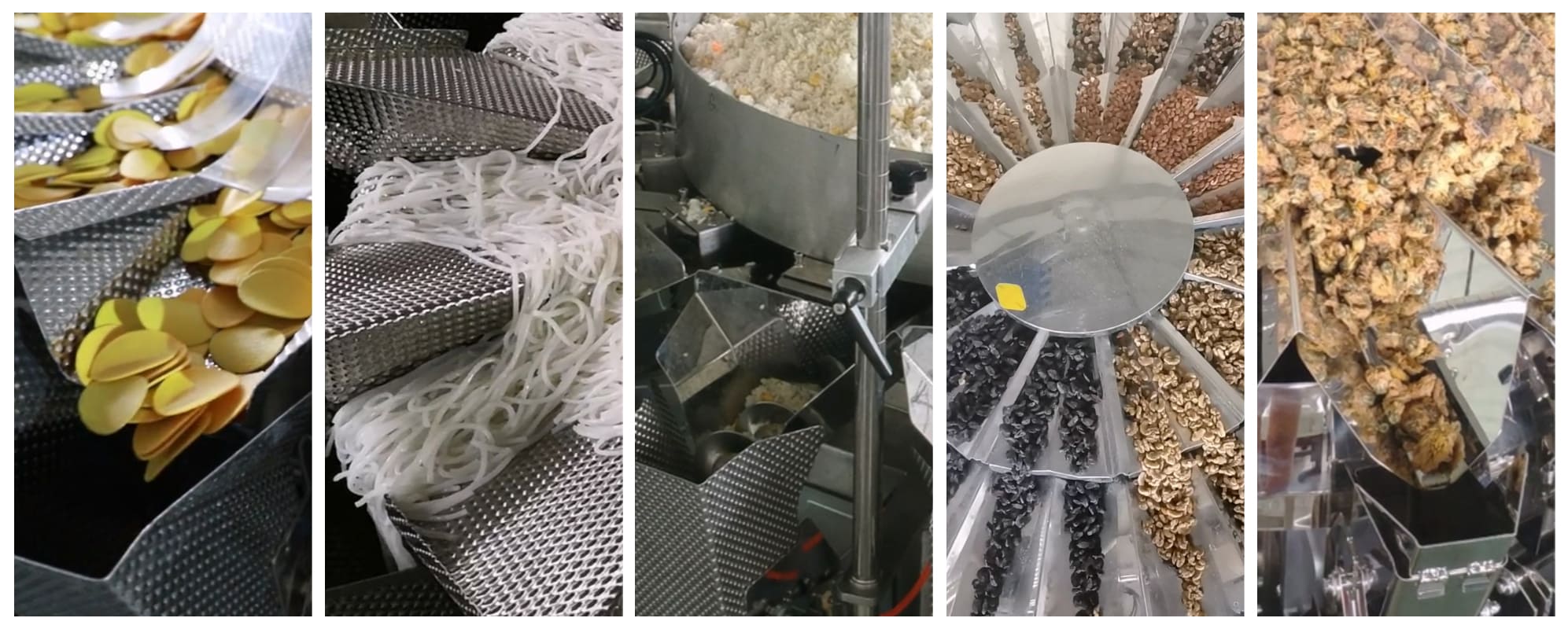

✔ Food businesses can use the multihead weigher packing machine for products like - popcorn, chips, and other snacking items. The machine can also be used for packaging of dried fruits, frozen foods, pet food, and chocolates.

✔Pharma companies can use the Multihead machine for packaging items like medicines, including powders and tablets. The machine is capable to properly weigh and pack even powdered medicines.

✔ In the consumer goods sector, the machine is suitable for packaging hardware items such as bolts, nuts, and screws among other things. Additionally, the machine is suited for the distribution of agricultural products like seeds.

Apart from these categories, the machine can also be used for other products, including detergent powders. The vast range of weigher packing machine has resulted in increased demand for the equipment over the last few years. In the section below, we have discussed where you can find the best multi head packing machine for your business needs.

With all that has been discussed in the above segments, it is no surprise that the multihead packing machine has been a game-changer in the packaging industry. With its ability offer unmatched precision and efficiency, and the capabilities to handle large volume it is becoming the go-to packing solution for businesses across different industries.

Although it has an initial investment involved, the machine does offer cost saving abilities over long periods of time. Its ability to streamline operations has caught the eye of many businesses around the world. Whether in food, pharmaceuticals, or consumer goods, the multihead machine is a good investment for businesses across sectors. If you are looking for a multihead weigher packing machine, then experienced packaging machines manufacturer -Smart Weigh has one available for your exact requirements. Get in touch today and bring home the Smart Weigh multihead packaging machine for packaging your products.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved