Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

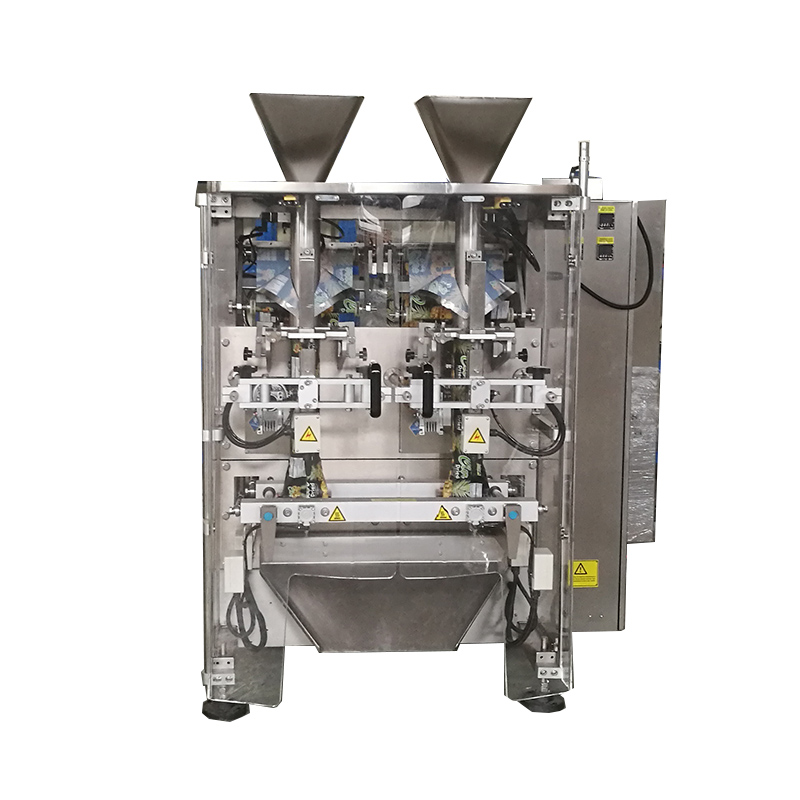

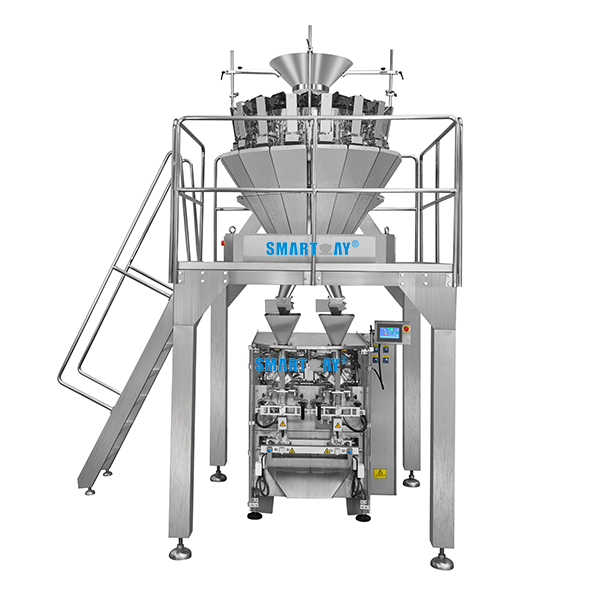

A dual VFFS machine consists of two vertical packaging units working simultaneously, effectively doubling the output compared to traditional single-lane systems. Food products ideal for dual VFFS include snacks, nuts, coffee beans, dried fruits, confectionery, and pet foods, where high volumes and rapid production cycles are crucial.

Many food manufacturers today, like a snack food producer, face challenges with outdated equipment that limits production speed, causes inconsistent sealing, and hampers their ability to meet rising market demand. To stay competitive, such manufacturers need advanced solutions that significantly increase throughput, enhance packaging consistency, and reduce operational costs.

Recognizing these industry challenges, Smart Weigh introduced a twin vertical packaging system to meet the demand for higher-speed production without expanding existing facility footprints. Smart Weigh's dual VFFS machine operates two independent packaging processes side-by-side, each capable of up to 80 bags per minute, delivering a total capacity of 160 bags per minute. This innovative system is focused on maximizing automation, precision, and overall operational efficiency.

Output Capacity: Up to 160 bags per minute (two lanes, each lane capable of 80 bags per minute)

Bag Size Range:

Width: 50 mm – 250 mm

Length: 80 mm – 350 mm

Packaging Formats: Pillow bags, gusseted bags

Film Material: Laminates films

Film Thickness: 0.04 mm – 0.09 mm

Control System: Advanced PLC with user-friendly for dual vffs, modular control system for multihead weigher, multilingual touchscreen interface

Power Requirements: 220V, 50/60 Hz, single-phase

Air Consumption: 0.6 m³/min at 0.6 MPa

Weighing Accuracy: ±0.5–1.5 grams

Servo Motors: High-performance servo motor-driven film pulling system

Compact Footprint: Designed for seamless integration within existing factory layouts

Enhanced Production Speeds

Capable of producing up to 160 bags per minute with dual lanes, significantly increasing throughput and meeting high-volume demands.

Improved Packaging Accuracy

Integrated multihead weighers ensure accurate weight control, minimizing product giveaway and maintaining consistent package quality.

Servo motor-driven film pulling systems facilitate precise bag formation, drastically reducing film waste.

Operational Efficiency

Significant reduction in manual labor requirements through increased automation.

Rapid changeover times and reduced downtime, optimizing overall equipment effectiveness (OEE).

Versatile Packaging Solutions

Adaptable to various bag sizes, styles, and packaging materials, ensuring broad applicability across different product lines.

As technology advances, dual VFFS machines are integrating IoT and smart sensors for predictive maintenance and operational insights. Innovations in sustainable packaging materials and highly customizable configurations will further drive the efficiency and adaptability of VFFS solutions.

The implementation of dual VFFS machines represents more than an incremental improvement—it's a substantial leap forward for food manufacturers aiming for higher productivity, accuracy, and profitability. As demonstrated by Smart Weigh's successful implementation, dual VFFS systems can redefine operational standards, ensuring businesses remain competitive in a demanding marketplace.

Connect with Smart Weigh today to explore how our dual VFFS solutions can elevate your production capabilities. Visit our website for more details, request a product demonstration, or speak directly with our experts.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved