Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

With the evolving world, industries are expanding, and with their expansion, there is a need for tools that aid in faster and reliable packing processes.

Whether we talk about food items, medicines, or any other product, they require good packaging, and the zipper pouch packing machine is the ultimate option to achieve it.

They offer great convenience to the industries by helping to pack products securely in less time. Thus, enhancing time efficiency. Following, we will walk you through the zipper pouch machine's key features, benefits, and their kinds. Let's begin.

There is an extensive list of zipper pouch packaging machines available in the market. Some of the significant options include:

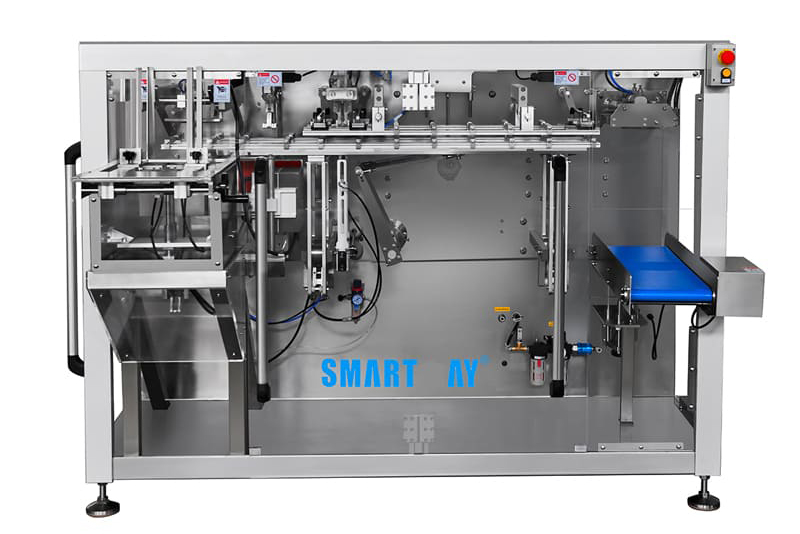

The horizontal pouch packing machines fill and seal pouches laid flat on the conveyor. They are an excellent solution for small-quantity pouch sizes and small-space factories.

The horizontal design facilitates high efficiency and ensures consistent results during the process. Businesses manufacturing items on a large scale usually utilize a horizontal pouch packing machine.

The rotary pouch packing machine loads the bag, opens it, and fits the material into the bag, followed by heat sealing. The rotary type is a cornerstone in modern packaging operations, renowned for its efficiency and reliability.

It has a compact design, which facilitates business with limited space. At the same time, this machine can handle multiple types of pouches at the same time, which results in a significant reduction in packaging time and resource wastage.

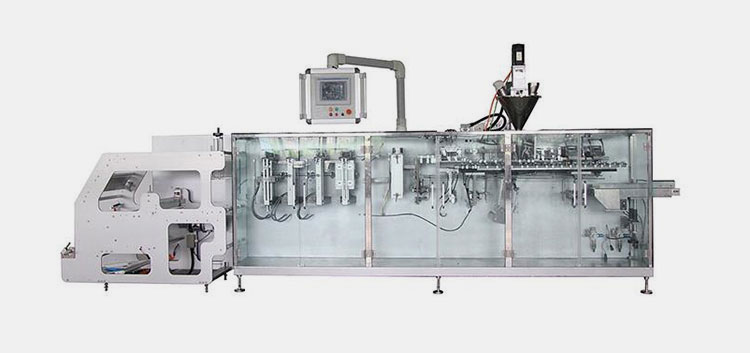

Horizontal form-fill-seal machines use flat rolls of film to create pouches that are then filled with the material. These machines are well-suited for larger volumes of production and specifically designed to perform tasks requiring high precision. Featuring a horizontal layout, these form-fill machines offer enhanced stability, which is the prime need of multiple industries, including food and beverages.

A Single station pouch packing machine is specially designed to pack products for small scale production. It seals and fills pouches at once to ensure maximum time-saving. Usually, the single station pouch packing machine is used to pack powdered granules and liquids in pre-formed packages.

In addition, the user-friendly interface and low maintenance are needed to establish it as an ideal option for beginners in packaging.

The zipper pouch filling Machine is designed to reduce labor work. There are some machines available that are completely automatic and come in extremely handy to save a lot of time. In addition, during the pouch formation, some machines only ask for a flat roll of material.

It makes the pouch itself from that into whatever size and shape you ask for. Thus, increasing efficiency of operations.

Sealing is what the machine does next after filling the pouches. The zipper pouch packaging machine usually has a heating mechanism that puts pressure on the opening and seals it securely. A tight packing helps keep the inside product fresh and secure.

The zipper packing machines can be adjusted according to the size of the packing. For instance, it can pack small products like medicines and food and larger ones like decoration pieces and much more.

With some particular packing machines, you can also customize the pouch in specific colors and designs.

A zipper pouch packing machine substitutes for immense labor work. Therefore, it reduces the cost that could have been spent on labor. In addition, the machines also help save a generous amount on several other things that could have required a huge amount for the packing process. Therefore, these machines are super cost-effective and minimize expenses.

The zipper pouch packing machine also helps increase customer satisfaction, which is important for any industry. It basically helps with easy-to-use packing that keeps the product inside safe and sound. Hence, customers are attracted to good packaging, which ultimately leads to brand loyalty.

Zipper pouch filling machines have diverse uses in the food industry. They are utilized in packing almost everything from frozen food items to grain and from liquid to ready-to-eat meals.

As these machines are airtight, the food inside gets maximum insulation and protection from moisture and contamination. At the same time, zipper closure allows for easy resealing.

In the pharmaceutical industry, protection from the contaminated environment is critical for medicines. Hence, the industry heavily relies upon packaging machines to prevent contamination and preserve product accuracy.

Furthermore, the machines also comply with strict packaging standards, which are integral in delivering safe and effective medical products.

Airtight seals prevent contamination and preserve product quality. These machines also securely package wipes and wet tissues. They are ideal for travel-sized items that require easy access. Zipper pouches are preferred for their reusability and convenience.

These machines offer quick and consistent packaging for a wide range of products. Personal care brands rely on them to ensure high-quality packaging.

Zipper packing machines are also used for household products. They package detergents, cleaning powders, and liquids. The resealable feature is ideal for product storage and use.

Furthermore, the zipper pouch packaging machine accommodates various sizes and materials to fit specific product needs. Household products benefit from the cost-effectiveness and efficiency these machines provide.

Zipper pouch machines are valuable in the industrial sector. They package items like screws, nuts, and bolts. The durable pouches protect small hardware from damage and dust.

Furthermore, the zip pouch packing machines are designed to handle high-volume production needs. They ensure packaging efficiency in fast-paced industrial environments. Industrial companies rely on these machines for reliable and consistent packaging.

Zipper pouch packing machines are essential for industries prioritizing efficiency, safety, and product presentation. The various types, like horizontal, rotary, and form fill seal machines, cater to specific needs. Each type is designed to optimize production processes in different operational scales.

The machine performs multiple roles in different industries, including improving product quality, enhancing usability, and reducing packaging time. Its ability to produce resealable pouches ensures convenience and an extended product lifespan.

In addition, the zipper pouch machines have applications in varied industries, including food, pharmaceuticals, personal care, and industrial packaging. Their versatility and functionality make them indispensable across sectors.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved