Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

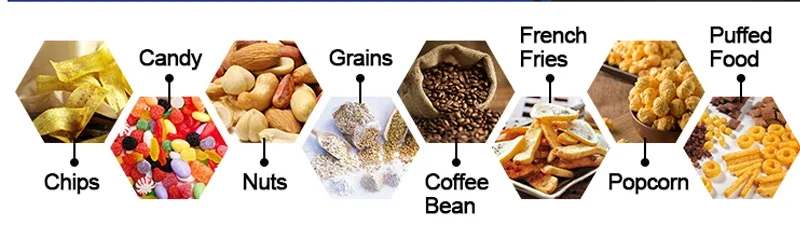

Have you ever thought that how can you pack granular products like nuts, rice, grains, and others into pouches when you buy them?

A granule packing machine can do this for you. It is an automatic machine that helps manufacturers pack nuts, salt, seeds, rice, desiccants, and different powders like coffee, milk-tea, and washing powder with auto filling, measuring, bag forming, code printing, sealing, and cutting.

Manufacturers can quickly choose a reliable brand by determining product size, type, packaging methods they require, and its sensitivity.

To learn more about a granule packaging machine, be there till the end.

A granule packing machine is a machine used to pack granular products like seeds, nuts, grains, rice, washing powders, desiccants, and other laundry beads. The machine does bag forming, weighing, filling, sealing and cutting of bags and pouches automatically.

Some machines used for granule packaging can also print logos and other things on the bags or pouches.

In addition, due to its high modern degree, many industries such as food, pharmaceuticals, agriculture, Pet, commodity, hardware, and chemical industries use it to pack their different granule products.

There are three types of granules packaging machine based on their level of automation. Manual, semi-automatic and fully automatic. This division is based on the automation degree.

Let's discuss them one by one.

As the name suggests, a manual packaging machine works through manual instructions where you will have to complete the bag making, filling, sealing, and cutting by yourself. Due to human involvement, it takes time to complete different processes.

Manual granule packaging machines are an excellent option for small-scale production, such as family usage. They are also easier to use than automatic ones.

Semi-automatic granule packing machine has a certain degree of automation that also needs human intervention during some processes. It has a PLC touch screen that you can use to turn on and off the machine. The screen is also used to set parameters, making it miore convenient than the manual one.

This semi-automatic packaging machine can pack 40-50 packs or pouches per minute, making it faster than the manual packaging machine and a great option for medium scale production.

A fully automatic granule packaging machine is an advanced, smart, and large-size packing machine with multihead weighing machine.

The machine’s large size helps it pack most kinds of granular products requiring different pouches with different size and thickness. In addition, it has large production capacities, making it the best option for large scale production demands, such as industrial level production.

It is essential to conduct a comprehensive and rigorous assessment when selecting a granular filling machine. Assess the adaptability, efficiency, and unwavering operational reliability of the machine that offers automatic measuring bag making, filling, sealing, and cuttings.

In addition, there are the following key factors to consider when choosing a packaging machine for granule packing.

● Product Size: The size and shape of your granular product greatly influence the selection of a granules packaging machine brand. Before you choose a packaging machine, analyze the product's size and form because specific forms and sizes require specific packaging. For example, a vertical packaging machine is the best for small-size granular products.

● Product Type: The next factor to consider is the type of product you want to pack. Is the product is in the solid, powdered, or granular? Similarly, whether the product is sticky or not. If sticky, the required machine needs to be treated with anti-stick materials.

● Packaging Methods: The next factor to consider is to check the packaging methods your granular products require. For example, either you need to pack granules in pouches, trays, boxes, cans, or bottles. Therefore, choosing a packaging method helps you choose the right brand of granule filling machine.

● Product Sensitivity: Some products are delicate, perishable and need refrigeration. Therefore, they require special handling during packaging. For example, you will need anti-breakage weighing machines to pack walnuts.

Understanding these factors helps you choose the best granule packaging granule machine brand.

A machine used for granule packaging has different applications in the following industries.

A granule packing machine is commonly used in the food industry for packing snacks, salt, sugar, and tea.

Agriculture uses granule packaging machines to pack grains, seeds, rice and soybeans.

The pharmaceutical industry uses granule packaging machines to pack capsules in specific amounts.

Some granular products of the commodity industry such as laundry detergents pods, washing pods, and descaling tablets, are packed in bags using granule packaging machines.

Granule packaging machines also have many applications in the chemical industry. They use them to pack fertilizer pellets and mothballs.

The granule packing machines also have great applications for the pet industry. These machines are used to pack pet foods and snacks into bags as some pet foods are also granular in nature.

A granule packing machine offers the following advantages:

The packing completes all the packing functions, including bag formation, measuring, filling, sealing, and cutting automatically in a single turn.

When you set sealing and cutting positions, the granule filling machine performs these functions neatly.

A granule packaging machine utilizes custom packaging materials such as BOPP/polyethylene, Aluminum/polyethylene, and Polyester/Aluminizer/Polyethylene to pack granules strongly.

The granule packing machines have a PLC touch screen that ensures smooth operations.

A granule packing machine involves the following packing phases:

● Product Filling System: In this phase, the products are loaded into the stainless steel hopper before the activation of the packaging process.

● Packing Film Transport: This is the second phase of a granules packaging machine where film transport belts are placed near the bag-forming section by peeling off a single sheet of the film.

● Bag Forming: In this phase, the film is precisely wrapped around the forming tubes by overlapping the two outside edges. This initiates the process of bag-forming.

● Sealing and Cutting: This is final step that a packaging machine performs to pack granules into the pouches or bags. A cutter equipped with the heater advances and cuts the bags of uniform size when the product has been loaded and placed inside.

Are you a person or company searching for a packing machine to speed up the granule packing process?

A granule filling machine can help you pack nuts, seeds, grains, and all kinds of granule products. Smart Weigh is one of the best and most reliable packaging machine manufacturers that offers fully automatic, weighing and packaging machines for all industries.

Our company has many systems installed across more than different countries and provides a range of packaging machines, including multi-head weigher, salad weigher, nut mixing weigher, vegetable weigher, meet weigher, and many other multi-dead packaging machines.

So, boost your production capacities with Smart Weigh’s automatic granule packing machines.

Get a granule packing machine by considering the product type, size, your packaging method, and sensitivity of the product to pack seeds, grains, nuts, rice, salt, and other granular products.

Businesses of all industries and sizes can leverage granule packaging machines as they use custom material to ensure smooth packing through neat sealing and cutting.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved