Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

In the bustling world of the dried fruit industry, the packing process is a critical aspect that ensures quality, freshness, and marketability. Smart Weigh, a leading manufacturer of dried fruit packing machines in China, is proud to present this comprehensive guide. Dive into the world of dried fruit packing and discover the technology, innovation, and expertise that Smart Weigh brings to the table.

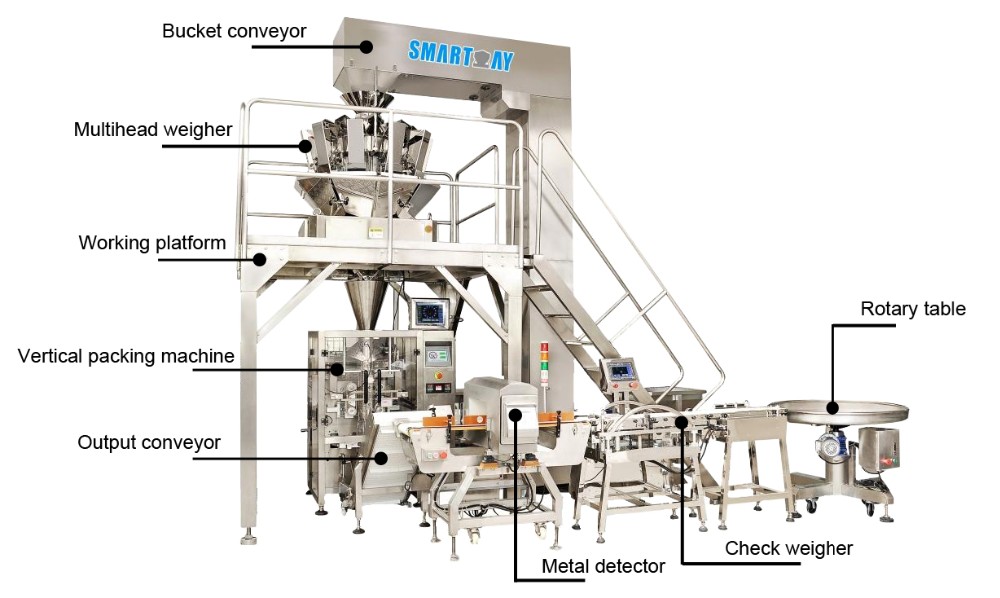

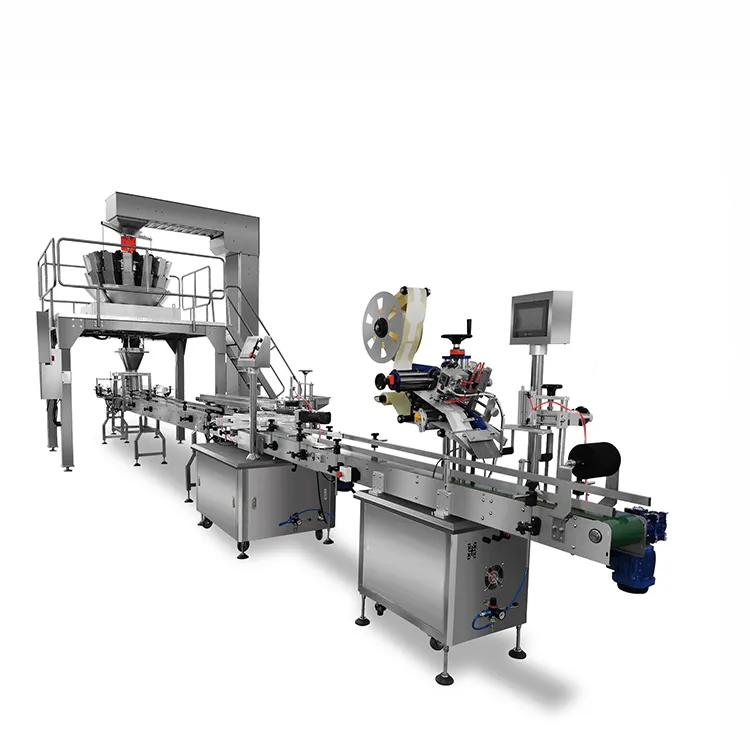

The Complete Packaging Solution is consisted of feed conveyor, multihead weigher(weigh filler), support platform, premade pouch packaging machine, finished pouches collect table and other inspection machine.

Pouch Loading: Premade pouches are loaded into the machine, either manually or automatically.

Pouch Opening: The machine opens the pouches and prepares them for filling.

Filling: Dried fruits are weighed and filled into the pouches. The filling system ensures that the correct amount of product is placed into each pouch.

Sealing: The machine seals the pouches to preserve freshness and prevent contamination.

Output: The filled and sealed pouches are discharged from the machine, ready for further processing or shipping.

Features:

Flexibility: The multihead weigher is suitable for weighing and filling most kinds of dried fruits, such as raisins, dates, prunes, figs, dried cranberries, dried mangoes and etc. Pouch packing machine can handle the premade pouches include zippered doypack and stand up pouches.

High-Speed Performance: Designed for mass production, these machines can handle large volumes with ease, speed is around 20-50 packs per minute.

User-Friendly Operation with Interface: Smart Weigh's automatic machines come with intuitive controls for ease of operation. Different dimension' pouches and weight parameters can be changed on touch screen directly.

The Pillow Bag Packing Machine is a versatile and efficient solution for creating pillow-shaped bags and gusset bags for a wide range of snacks, dry fruits and nuts. Its automation and precision make it a valuable asset for businesses looking to enhance their packaging processes.

The typical process includes:

Forming: The machine takes a roll of flat film and folds it into the shape of a tube, creating the main body of the pillow bag.

Date-printing: A ribbon printer is with standard vffs machine, which can print the simple date and letters.

Weighing and Filling: The product is weighed and dropped into the formed tube. The machine's filling system ensures that the correct amount of product is placed into each bag.

Sealing: The machine seals the top and bottom of the bag, creating the characteristic pillow shape. The sides are also sealed to prevent leakage.

Cutting: The individual bags are cut from the continuous tube of film.

Key features:

Flexibility: Ideal for businesses that require adaptability in packing various products.

Speed: These machines can produce a large number of(30-180) pillow bags per minute, making them suitable for high-volume production.

Cost-Effective: A budget-friendly option without compromising on quality.

Dried Fruit Jar Packing Machine are specialized packaging equipment designed to fill jars with dried fruits. These machines automate the process of filling jars with dried fruits, ensuring accuracy, efficiency, and hygiene.

The process typically involves the following steps:

Weighing and filling: The dried fruits are weighed to ensure that each jar contains the correct amount.

Sealing: The jars are sealed to preserve freshness and prevent contamination.

Labeling: Labels containing product information, branding, and other details are applied to the jars.

Precision

* Accuracy: Our dried fruit packing machines ensure that each package is filled with the exact amount, reducing wastage.

* Consistency: Uniform packaging enhances brand image and customer trust.

Speed

* Efficiency: Capable of packing hundreds of units per minute, our machines save valuable time.

* Adaptability: Easily adjustable settings to cater to different packing needs.

Hygiene

* Food-Grade Materials: Compliance with international hygiene standards is our priority.

* Easy Cleaning: Designed for effortless cleaning to maintain hygiene.

Customization

* Tailored Solutions: From bag styles to packaging materials, we offer customized solutions.

* Integration: Our machines can be integrated with existing production lines.

Smart Weigh's dried fruit packing machines are designed with the environment in mind. Energy-efficient operations and waste reduction strategies align with global sustainability goals.

Regular Maintenance

* Scheduled Check-ups: Regular inspections ensure optimal performance.

* Replacement Parts: Genuine parts available for maintenance needs.

Training and Customer Service

* On-Site Training: Our experts provide hands-on training for your staff.

* 24/7 Support: A dedicated team is available around the clock to assist you.

Explore real-life examples of businesses that have thrived using Smart Weigh's packing solutions. From small startups to industry giants, our dried fruit packing machines have proven their worth.

Choosing the right dried fruit packing machine is a decision that shapes the success of your business. Smart Weigh's commitment to quality, innovation, and customer satisfaction makes us a preferred choice in the industry.

Contact us today to explore our wide range of solutions and take a step towards achieving your business goals. With Smart Weigh, you're not just buying a machine; you're investing in a partnership that lasts.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved