Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

As leading manufacturer of pouch packing machine from China, we often encounter questions about the types, functionalities, and materials used in these machines from customers. What makes pouch packing machines so essential in today's packaging industry? How can businesses leverage them for efficiency and sustainability?

Pouch packing machines are transforming the way products are packaged, offering flexibility, precision, and customization. They cater to various industries, including food, pharmaceuticals, and cosmetics, providing tailored solutions for different packaging needs.

Understanding these machines is crucial for businesses looking to invest in modern packaging solutions. Let's delve into the comprehensive guide to pouch packing machines.

Pouch packaging machines offer numerous advantages, such as enhanced efficiency, less waste, and product protection. How do these benefits translate into real-world applications?

Enhanced Efficiency: Auto-bagging machines automate tedious tasks, saving time and labor costs. According to customers feedback, automation can improve efficiency by up to 40%.

Less Waste: Automated control reduces product waste and packaging material costs. Our customers feedback Research shows that automation can reduce waste by 30%.

Less labor cost: Semi-automatic filling lines help customers save at least 30% labor, fully automatic packing machine system saves 80% labor compared with traditional manual weighing and packing.

Product Protection: Customizable machines ensure product safety and reduce contamination risks.

Pouch packing machines are categorized into Premade Pouch Packing Machines, Vertical Form Fill Seal (VFFS) Machines and Horizontal Form Fill Seal (HFFS) Machines. What distinguishes these types?

Premade Pouch Packing Machine: Custom-designed to fill ready-made pouches with various products, like premade flat pouche, stand up pouches, zippered doypack, side gusseted pouches, 8 side seal pouches and sprout pouches.

Vertical Form Fill Seal Machines: Ideal both for small and high production speed, these machines create pouches from a roll of film. High Speed vertical form fill seal machines are preferred for snack foods large-scale operations. Besides the standard bag shape lke pillow bags and gusseted pouches, vertical packing machine also can form quad-sealed bags, flat-bottom bags, 3 side and 4 side seal bags.

HFFS Machines: This type of machinery are common used in Europe, similar with vffs, hffs is suitable for solid, single-item products,liquids, these machines package products in a flat, stand up pouches or customize inregular shape pouches.

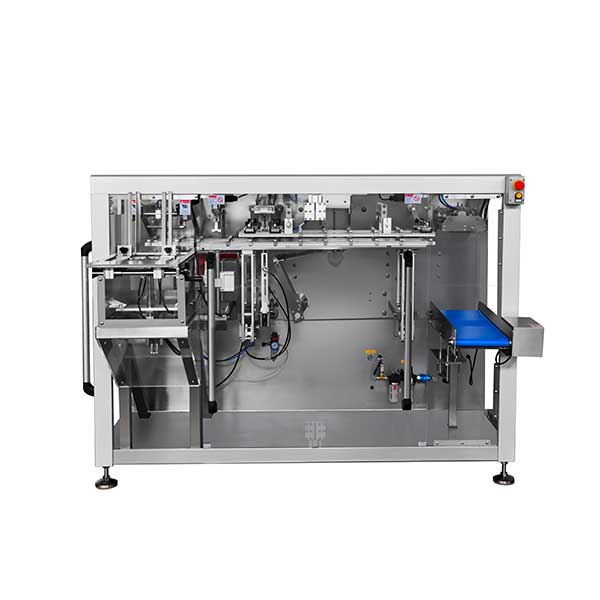

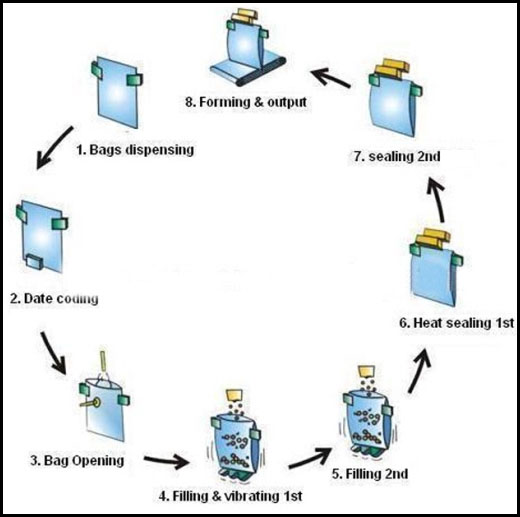

A premade pouch packing machine is a specialized packaging equipment designed to fill and seal already formed pouches. Unlike Vertical Form Fill Seal (VFFS) machines, which create pouches from a roll of film, premade pouch packing machine handle pouches that are already shaped and ready for filling. Here's how a premade pouch packing machine works:

1. Pouch Loading

Manual Loading: Operators can manually place premade pouches into the machine's holders.

Automatic Picking-up: Some machines have automatic feeding systems that pick and place pouches into position.

2. Pouch Detection and Opening

Sensors: The machine detects the pouch's presence and ensures it's in the correct position.

Opening Mechanism: Specialized grippers or vacuum systems open the pouch, preparing it for filling.

3. Optional Date Printing

Printing: If required, the machine can print information like expiration dates, batch numbers, or other details on the pouch. In this station, pouch packaging machines can equip with ribbon printer, Thermal transfer printers(TTO) and even laser coding machine.

4. Filling

Product Dispensing: The product is dispensed into the open pouch. This can be done using various filling systems, depending on the product type (e.g., liquid, powder, solid).

5. Deflation

A deflation device to remove excess air from the pouch before sealing, ensuring that the contents are tightly packed and preserved. This process minimizes the volume within the packaging, which can lead to a more efficient use of storage space and potentially enhance the shelf life of the product by reducing exposure to oxygen, a factor that might contribute to spoilage or degradation of certain materials. Additionally, by removing the excess air, the deflation device prepares the pouch for the next step of sealing, creating an optimal environment for a secure and consistent seal. This preparation is vital in maintaining the integrity of the package, preventing potential leaks, and ensuring that the product remains fresh and uncontaminated during transportation and storage.

6. Sealing

Heated sealing jaws or other sealing methods are used to securely close the pouch. It's important to note that the design of the sealing jaws for laminated pouches and PE (Polyethylene) pouches is different, and their sealing styles vary as well. Laminated pouches may require a specific sealing temperature and pressure, while PE pouches might need a different setting. Therefore, understanding the differences in sealing mechanisms is essential, and it is crucial to know your package material in advance.

7. Cooling

The sealed pouch may pass through a cooling station to set the seal, the pouch seal is cooled to prevent deformation due to high temperature at the seal during subsequent packaging processes.

8. Discharge

The finished pouch is then discharged from the machine, either manually by an operator or automatically onto a conveyor system.

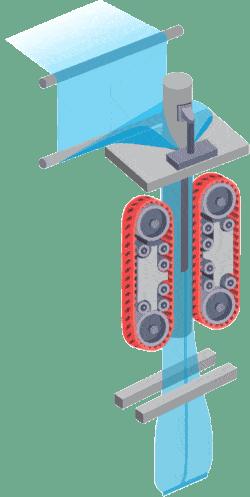

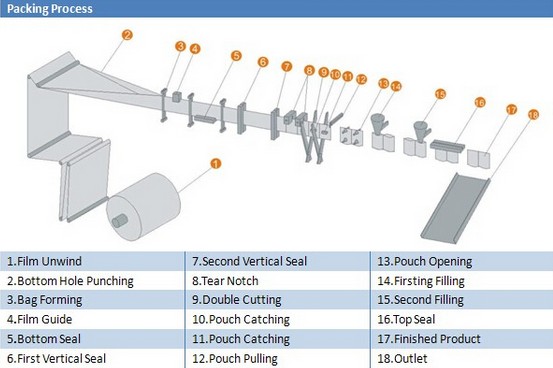

Vertical Form Fill Seal (VFFS) machines are a popular choice in the packaging industry for their efficiency and versatility. Here's how a VFFS machine works, broken down into key stages:

Film Unwinding: A roll of film is loaded onto the machine, and it's unwound as it moves through the process.

Film Pulling System: The film is pulled through the machine using belts or rollers, ensuring a smooth and consistent flow.

Printing (Optional): If required, the film can be printed with information such as dates, codes, logos, or other designs using thermal or ink-jet printers.

Film Positioning: Sensors detect the position of the film, ensuring it's aligned correctly. If any misalignment is detected, adjustments are made to reposition the film.

Pouch Formation: The film is fed over a cone-shaped forming tube, shaping it into a pouch. The two outer edges of the film overlap or meet, and a vertical seal is made to create the back seam of the pouch.

Filling: The product to be packaged is dropped into the formed pouch. The filling apparatus, such as a multi-head scale or auger filler, ensures the correct measurement of the product.

Horizontal Sealing: Heated horizontal sealing jaws join to seal the top of one bag and the bottom of the next. This creates the top seal of one pouch and the bottom seal of the next one in line.

Pouch Cut: The filled and sealed pouch is then cut from the continuous film. Cutting can be done using a blade or heat, depending on the machine and material.

Finished Bag Conveying: The finished pouches are then conveyed to the next stage, such as inspection, labeling, or packing into cartons.

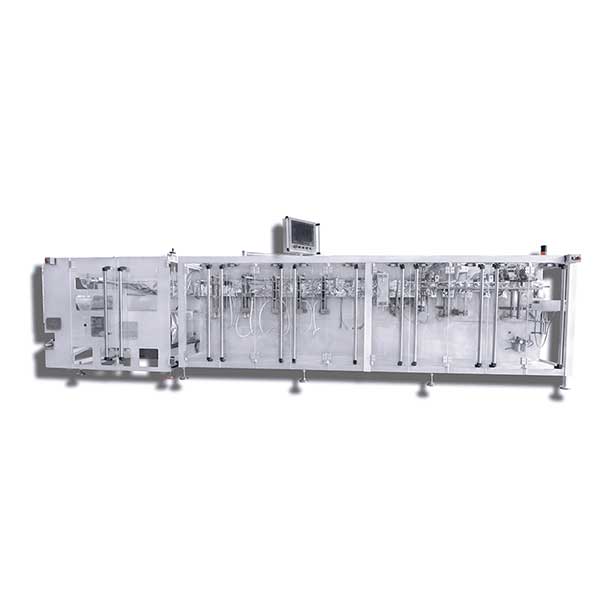

A Horizontal Form Fill Seal (HFFS) machine is a type of packaging equipment that forms, fills, and seals products in a horizontal fashion. It's particularly suitable for products that are solid or individually portioned, such as biscuits, candies, or medical devices. Here's a detailed breakdown of how an HFFS machine operates:

Film Transport

Unwinding: A roll of film is loaded onto the machine, and it's unwound horizontally as the process begins.

Tension Control: The film is kept at a consistent tension to ensure smooth movement and accurate pouch formation.

Pouch Formation

Forming: The film is shaped into a pouch using specialized molds or shaping tools. The shape can vary based on the product and packaging requirements.

Sealing: The sides of the pouch are sealed, typically using heat or ultrasonic sealing methods.

Film Positioning and Guiding

Sensors: These detect the position of the film, ensuring it's aligned correctly for accurate pouch formation and sealing.

Vertical Sealing

The vertical edges of the pouch are sealed, creating the side seams of the pouch. This is where the term "vertical sealing" comes from, even though the machine operates horizontally.

Pouch Cutting

Cutting from Continuous Film and separating individual pouches from a continuous roll of film.

Pouch Opening

Opening the Pouch: The pouch opening function ensures that the pouch is properly opened and ready to receive the product.

Alignment: The pouch must be correctly aligned to ensure that the opening mechanism can effectively access and open the pouch.

Filling

Product Dispensing: The product is placed or dispensed into the formed pouch. The type of filling system used depends on the product (e.g., gravity filling for liquids, volumetric filling for solids).

Multi-Stage Filling (Optional): Some products may require multiple filling stages or components.

Top Sealing

Sealing: The top of the pouch is sealed, ensuring the product is securely contained.

Cutting: The sealed pouch is then separated from the continuous film, either through a cutting blade or heat.

Finished Pouch Conveying

The finished pouches are conveyed to the next stage, such as inspection, labeling, or packing into cartons.

The choice of material is crucial for the quality and sustainability of the product. What are the common materials used in pouch packaging?

Plastic Films: Including multi layer films and single layer films like Polyethylene (PE), Polypropylene (PP), and Polyester (PET).

Aluminum Foil: Used for complete barrier protection. Research highlights its applications.

Paper: A biodegradable option for dry goods. This study discusses its benefits.

Recycle package: mono-pe recyclable packaging

The integration of weighing machines with pouch packing systems is a critical aspect of many packaging lines, especially in industries where precise measurements are essential. Various types of weighing machines can be paired with pouch packing machine, each offering unique advantages depending on the product and packaging requirements:

Usage: Ideal for granular and irregularly shaped products like snacks, candies, and frozen foods.

Functionality: Multiple weighing heads work simultaneously to achieve accurate and rapid weighing.

Usage: Suitable for free-flowing granular products like sugar, salt, and seeds.

Functionality: Utilizes vibrating channels to feed the product into weigh buckets, allowing for continuous weighing.

Usage: Designed for powdery and fine-grained products like flour, milk powder, and spices.

Functionality: Uses an auger screw to dispense the product into the pouch, providing controlled and dust-free filling.

Usage: Works well with products that can be accurately measured by volume, such as rice, beans, and small hardware.

Functionality: Employs adjustable cups to measure the product by volume, offering a simple and cost-effective solution.

Usage: Versatile and can handle a wide variety of products, including mixed products.

Functionality: Combines the features of different weighers, allowing for flexibility and precision in weighing various components.

Usage: Specifically designed for liquids and semi-liquids like sauces, oils, and creams.

Functionality: Utilizes pumps or gravity to control the flow of liquid into the pouch, ensuring accurate and spill-free filling.

Pouch packing machine are versatile and essential tools for modern packaging needs. Understanding their types, workings, and materials is key to leveraging their benefits for business growth. Investing in the right machine can significantly enhance efficiency, reduce waste, and ensure product quality.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved