How Can Automatic Coffee Packaging Machines Boost Your Business?

Struggling with inconsistent bag weights, slow manual packing, and the constant threat of your roasted beans losing freshness? You need a solution that protects your coffee's quality and scales with your brand.

Automatic coffee packaging machines solve these problems by providing speed, precision, and superior protection. They ensure accurate weights, create perfect seals, and offer features like nitrogen flushing to preserve aroma, helping you grow your roastery efficiently while delighting your customers with fresh coffee every time.

I've walked through countless roasteries, and I see the same passion everywhere: a deep commitment to the quality of the bean. But often, that passion is bottlenecked in the final step—packaging. I've seen teams of people hand-scooping precious single-origin beans, struggling to keep up with orders from cafes and online customers. They know there's a better way. Let's explore how automation can solve these specific challenges and become the engine for your coffee brand's growth.

Does Automation Really Improve Your Roastery's Efficiency and Speed?

Is the post-roasting packaging process a constant bottleneck, limiting how much coffee you can ship out each day? Manual scooping and sealing are slow, labor-intensive, and can't keep up with large orders from retailers or wholesale clients.

Absolutely. Automated coffee packaging systems are built for speed and consistency. They can accurately weigh and pack dozens of bags per minute, a pace that's impossible to maintain manually. This allows you to fulfill large orders faster and get your freshly roasted coffee to customers without delay.

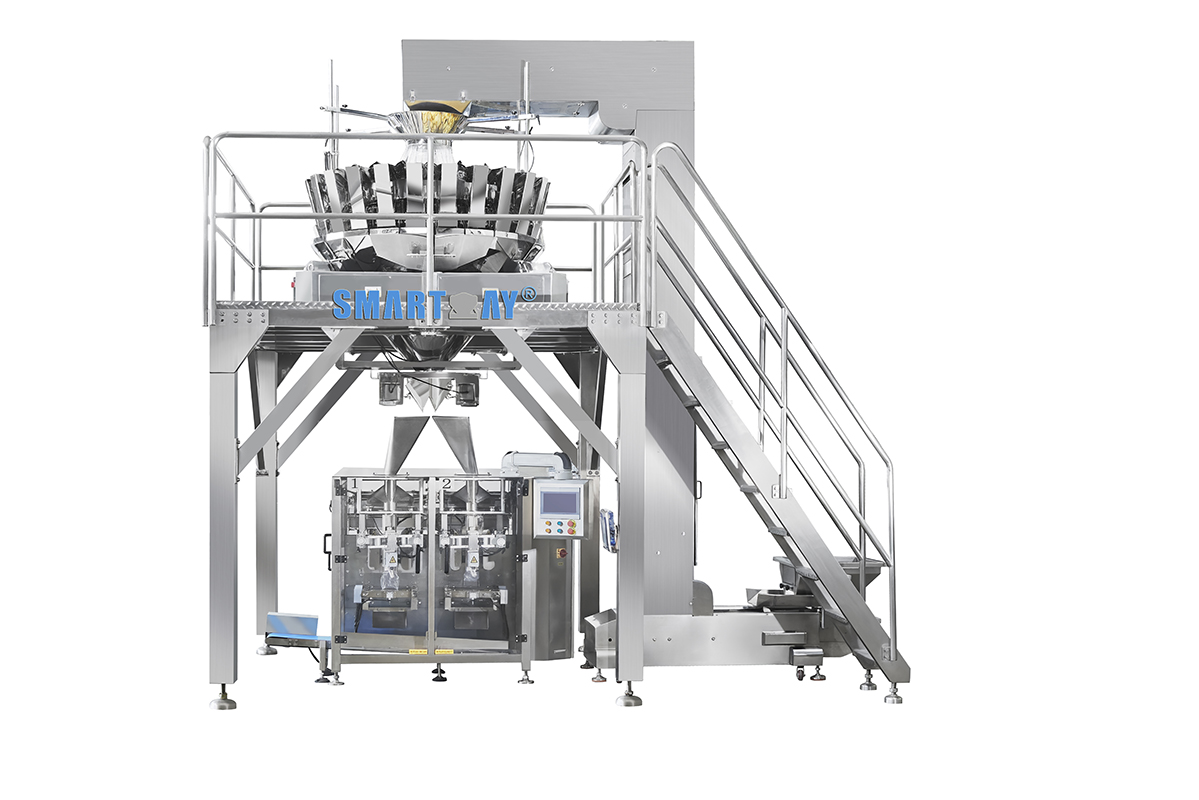

The leap from manual to automated packaging is a game-changer for a roastery. I remember visiting a growing coffee brand that was hand-packing their signature espresso blend. A dedicated team could manage about 6-8 bags a minute if they pushed hard. After we installed a Smart Weigh multihead weigher with a premade pouch machine, their output jumped to 45 bags per minute. That’s over a 400% increase in productivity, allowing them to take on a new contract with a major grocery chain they previously couldn't handle.

Beyond Speed: Achieving True Efficiency

The benefits go beyond just bags-per-minute. Machines deliver consistent performance, hour after hour.

| Metric | Manual Coffee Packaging | Automated Coffee Packaging |

|---|---|---|

| Bags per Minute | 5-10 | 30-60+ |

| Uptime | Limited by labor shifts | Up to 24/7 Operation |

| Consistency | Varies by worker & fatigue | Extremely High, with <1% error |

Slashing Downtime for Different Blends and Sizes

Coffee brands thrive on variety. One minute you're packing 12oz retail bags of whole beans, the next you're running 5lb bags of ground coffee for a wholesale client. Manually, this changeover is slow and messy. With our automated systems, you can save the settings for each coffee blend and bag size as a "recipe." An operator simply selects the next job on the touchscreen, and the machine adjusts itself in minutes. This turns hours of downtime into profitable production time.

How Does Automation Cut Your Coffee Business's Costs?

Are the rising costs of green beans, labor, and giving away a little extra coffee in every bag eating into your margins? Every gram of your carefully sourced and roasted coffee is valuable.

Automation tackles costs directly. It reduces your reliance on manual packing labor, cutting wage expenses. More importantly, our high-precision multihead weighers minimize coffee giveaway, ensuring you aren't giving away profits with every bag.

Let's be specific about where the savings come from for a coffee business. Labor is the obvious one. A manual packing line of four or five people can be managed by a single operator overseeing an automated system. This frees up your valuable team members to focus on other critical areas like roasting, quality control, or customer service.

Can Automated Packaging Preserve Your Coffee's Freshness and Quality?

Is your biggest fear that your perfectly roasted coffee will go stale on the shelf due to poor packaging? Oxygen is the enemy of fresh coffee, and an inconsistent seal can ruin the customer experience and damage your brand's reputation.

Yes, automation is essential for preserving the quality of your coffee. Our machines create strong, consistent, hermetic seals on every bag. They can also integrate nitrogen flushing to displace oxygen, protecting the delicate aroma and flavor profile of your beans.

The quality of your coffee is your most important asset. The package's job is to protect it. A machine applies the exact same heat, pressure, and time to seal every single bag, something impossible to replicate by hand. This consistent, airtight seal is the first line of defense against staleness.

The Science of Freshness: Valves and Nitrogen Flushing

But for coffee, we go a step further.

One-Way Degassing Valves: Freshly roasted coffee releases CO2. Our packaging machines can automatically apply one-way valves to your bags. This lets the CO2 escape without letting damaging oxygen in. Manually applying these valves is slow and prone to error; automation makes it a seamless, reliable part of the process.

Nitrogen Flushing: To provide the ultimate protection, many of our systems use nitrogen flushing. Just before the final seal, the machine flushes the inside of the bag with nitrogen, an inert gas. This displaces the oxygen, effectively stopping the oxidation process in its tracks and dramatically extending the coffee’s shelf life and peak flavor. This is a level of quality control that sets premium brands apart.

What Are the Main Types of Coffee Packaging Machines?

Trying to figure out the right machine for your coffee beans or ground coffee? The options can seem confusing, and choosing the wrong one can limit your brand's potential and efficiency.

The primary coffee packaging machines are VFFS machines for speed and economy, premade pouch machines for a premium look with features like zippers, and capsule/pod lines for the single-serve market. Each is designed for a specific type of packaging and production scale.

Choosing the right machine is critical in the competitive coffee market. Your packaging is the first thing a customer sees, and it needs to communicate the quality of the product inside. It also has to preserve freshness, which is paramount for coffee. The machine you choose will define your production speed, your material costs, and the look and feel of your final product. Let's break down the main families of machines we offer for coffee producers.

Comparing Your Options

Each machine type has distinct advantages depending on your specific goals, from high-volume wholesale to premium retail brands.

| Machine Type | Best For | Description |

|---|---|---|

| VFFS Machine | High-speed, simple bags like pillow and gusseted bags. Ideal for wholesale and food service. | Forms bags from a roll of film, then fills and seals them vertically. Very fast and cost-effective. |

| Premade Pouch Machine | Stand-up pouches (doypacks), flat-bottom bags with zippers and valves. Great for premium retail looks. | Picks up pre-made bags, opens, fills, and seals them. Offers superior branding and consumer convenience. |

| Capsule/Pod Line | K-Cups, Nespresso-compatible capsules. | A fully integrated system that sorts empty capsules, fills them with coffee, tamps, seals, and flushes with nitrogen. |

For many roasters, the choice comes down to VFFS versus premade pouch. VFFS is the workhorse for speed and low cost per bag, perfect for getting large quantities out the door to cafes and restaurants. However, the premade pouch machine offers the flexibility to use high-quality, pre-printed bags with degassing valves and resealable zippers—features that retail customers love. These premium bags command a higher price point and build a stronger brand identity on the shelf.

Is an Automated System Flexible Enough for Your Growing Coffee Brand?

Your coffee brand is dynamic. You have multiple SKUs—different origins, blends, grinds, and bag sizes. You worry that a large machine will lock you into one format, stifling your creativity and ability to adapt.

Modern automated packaging systems are engineered for flexibility. Our machines are designed for quick and easy changeovers. With programmable controls, you can switch between different coffee products, bag sizes, and pouch types in minutes, giving you the agility to grow your brand.

This is a common concern I hear from roasters. Their strength lies in their diverse offerings. The great news is that modern automation supports this, not hinders it. I worked with a specialty coffee roaster who needed to be incredibly agile. On a Monday morning, they might be running 12oz stand-up pouches with zippers for their premium single-origin Geisha. In the afternoon, they need to switch to 5lb gusseted bags of their house blend for local cafes. They thought they'd need two separate lines. We set them up with a single, flexible solution: one multihead weigher that could handle whole beans and ground coffee, paired with a premade pouch machine that could adjust for both pouch types in under 15 minutes.

A Modular Path to Growth

The key is a modular approach. You can build your packaging line as your brand grows.

Start: Begin with a high-precision multihead weigher and a bagger (VFFS or premade pouch).

Expand: As volume increases, add a check weigher to verify every bag's weight and a metal detector for ultimate safety.

Automate Fully: For high-volume operations, add a robotic case packer to automatically place finished bags into shipping cases.

This ensures your investment today is a foundation for your success tomorrow.

Conclusion

Automating your coffee packaging is about more than just speed. It's about protecting the quality of your roast, cutting hidden costs, and building a brand that can scale without compromise.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine