The Ultimate Coffee Packing Machine FAQ: What Do You Need To Know?

Choosing a coffee packing machine feels overwhelming. You know automation is key, but the options are endless and a wrong choice could hurt your bottom line. We're here to break it down.

The right coffee packing machine depends on your product (beans or ground), bag style, and production speed. For beans, a multihead weigher with a VFFS or premade pouch machine is best. For ground coffee, an auger filler is essential to handle the fine powder accurately.

I've walked through countless coffee roasting facilities and I see the same questions come up again and again. You need a trusted partner, not just a machine supplier. My goal with this guide is to give you the clear, simple answers I share with our partners every day. We'll go through everything from coffee formats to the total cost, so you can make the right decision for your brand. Let's get started.

What do you need to know before buying a coffee packing machine?

You're ready to grow your coffee business. But navigating the world of machinery is complex, and you aren't sure where to start. This guide gives you a clear roadmap.

This guide is for coffee roasters, co-packers, and private-label brands. We cover everything you need to know, from matching the right machine to your coffee type (beans vs. ground) to choosing the best bag styles, and designing a complete, efficient packaging line.

Whether you're a startup moving from manual bagging or a large-scale roaster looking to increase your output, the core challenges are similar. You need to protect your coffee's freshness, create a great-looking product on the shelf, and do it all efficiently and reliably. I've seen startups struggle with choosing a machine that can grow with them, while industrial operations need to maximize uptime and reduce waste. This guide addresses the key decision points for everyone. We will look at the specific technologies for different coffee formats, the films and features that keep your coffee fresh, and the factors that determine your total cost of ownership. By the end, you'll have a solid framework to choose the perfect system.

Which machine matches your coffee format?

Your coffee is unique. Whether it's whole beans or fine ground, the wrong machine will cause product giveaway, dust problems, and inaccurate weights. You need a solution built for your specific product.

The primary choice is between a multihead weigher for whole beans and an auger filler for ground coffee. Whole beans flow freely, making them perfect for precise weighing. Ground coffee is dusty and doesn't flow easily, so it requires an auger to dispense it accurately.

Let's dive deeper into this because it's the most critical decision you'll make.

Whole Beans vs. Ground Coffee?

Whole beans are relatively easy to handle. They flow well, which is why we almost always recommend a multihead weigher. It uses multiple small buckets to combine portions to hit a perfect target weight. This is incredibly accurate and minimizes expensive giveaway. Ground coffee is a different story. It creates dust, can hold a static charge, and doesn't flow predictably. For grounds, an auger filler is the industry standard. It uses a rotating screw to dispense a specific volume of coffee into the bag. While volumetric, it's highly repeatable and designed to control dust. Using the wrong filler leads to big problems. A weigher would get clogged with coffee dust, and an auger can't accurately portion whole beans.

What are the main machine types?

Once you've chosen your filler, it feeds into the bagger. There are four main families of machines:

| Machine Type | Best For | Description |

|---|---|---|

| VFFS Machine | High-speed, simple bags like pillows and gusseted bags. | Forms bags from a roll of film, then fills and seals them vertically. Very fast. |

| Premade Pouch Machine | Stand-up pouches (doypacks), flat-bottom bags with zippers. | Picks up pre-made bags, opens, fills, and seals them. Great for premium looks. |

| Capsule/Pod Line | K-Cups, Nespresso compatible capsules. | A fully integrated system that sorts, fills, tamps, seals, and flushes pods with nitrogen. |

| Drip Coffee Bag Line | Single-serve "pour-over" style drip coffee bags. | Fills and seals the coffee filter bag and often places it into an outer envelope. |

How can you keep your coffee fresh with the right bag and features?

Your carefully roasted coffee can go stale on the shelf. The wrong packaging material or a missing valve means customers get a disappointing brew. You need to lock in that freshness.

Your packaging is your best defense. Use a high-barrier film with a one-way degassing valve. This combination lets CO2 out without letting oxygen in, which is the key to preserving the flavor and aroma of your coffee from roaster to cup.

The bag itself is more than just a container; it's a complete freshness system. Let's break down the components you need to consider. From the shape of the bag to the layers of film, every choice impacts how your customer experiences your coffee.

What are the common bag types?

The bag style you choose affects your branding, shelf presence, and cost. A premium, flat-bottom bag looks great but costs more than a simple pillow bag.

| Bag Type | When to Use It |

|---|---|

| Doypack / Stand-Up Pouch | Excellent shelf presence, ideal for retail. Often includes a zipper for resealability. |

| Flat-Bottom / Box Pouch | Premium, modern look. Sits very stable on shelves, providing five panels for branding. |

| Quad-Seal Bag | Strong, clean look with seals on all four corners. Often used for mid to large-volume bags. |

| Pillow Bag | The most economical choice. Perfect for fractional packs or bulk "bag-in-box" applications. |

What film materials and features are important?

The film protects your coffee from oxygen, moisture, and light. A typical high-barrier structure is PET / AL / PE (Polyethylene Terephthalate / Aluminum Foil / Polyethylene). The aluminum layer provides the best barrier. For features, the one-way degassing valve is non-negotiable for whole bean coffee. It allows CO2 released after roasting to escape without letting damaging oxygen in. For consumer convenience, zippers and tin-ties are fantastic for resealing the bag after opening. Newer, recyclable film options are also becoming more available if sustainability is a key part of your brand.

How does Nitrogen Flushing work?

Modified Atmosphere Packaging (MAP), or nitrogen flushing, is a simple but powerful technique. Before the final seal, the machine injects a puff of inert nitrogen gas into the bag. This gas displaces the oxygen. Why does this matter? Oxygen is the enemy of fresh coffee. Reducing the residual oxygen inside the bag from 21% (normal air) to less than 3% can dramatically extend shelf life, preserving the coffee's delicate aromas and preventing stale flavors. It's a standard feature on nearly all modern coffee packing machines and is essential for any serious roaster.

What's involved in a coffee capsule filling and sealing line?

The single-serve market is booming, but manual production is impossible. You worry about inconsistent fills and poor seals, which can ruin your brand's reputation before it even starts.

A complete coffee capsule line automates the entire process. It precisely drops empty cups, fills them with coffee using an auger, tamps the grounds, flushes with nitrogen for freshness, applies and seals the lid, and then outputs the finished pod for packaging.

I've seen many partners hesitate before entering the capsule market because it seems so technical. But a modern, integrated system like our Smart Weigh SW-KC series simplifies the entire workflow. It’s not just one machine; it’s a complete production solution designed for precision and speed. Let's look at the key stages.

How do you get a consistent dose in every cup?

For capsules, accuracy is everything. Customers expect the same great taste every time. Our SW-KC machines use a high-resolution servo-driven auger filler with real-time weight feedback. This system constantly checks and adjusts the fill amount to maintain an accuracy of ±0.2 grams. This precision means you don't give away product, and you deliver a consistent flavor profile, even with fine-ground specialty coffees. The machine stores "recipes" for different blends, so you can switch between them with zero manual adjustments, cutting changeover time to less than five minutes.

How do you ensure freshness and a perfect seal?

A bad seal on a K-Cup is a disaster. It lets oxygen in and ruins the coffee. Our system uses a proprietary heat-sealing head that adapts to small variations in the lid material. This creates a firm, wrinkle-free seal that looks great on the shelf and protects the coffee inside. Just before sealing, the machine flushes the cup with nitrogen, pushing out the oxygen. This process is critical for extending shelf life and preserving the delicate aromas of your coffee, ensuring the last pod tastes as fresh as the first. Here is a quick look at the specifications for one of our popular models:

| Model | SW-KC03 |

|---|---|

| Capacity | 180 cups/minute |

| Container | K cup/capsule |

| Filling Weight | 12 grams |

| Accuracy | ±0.2g |

| Power consumption | 8.6KW |

| Air consumption | 0.4m³/min |

| Pressure | 0.6Mpa |

| Voltage | 220V, 50/60HZ, 3 phase |

| Machine Size | L1700×2000×2200mm |

How fast can these machines actually run?

Speed and efficiency are key to profitability in the single-serve market. Our SW-KC series features a rotary turret design that handles three capsules at every cycle. Running at 60 cycles per minute, the machine delivers a sustained, real-world output of 180 capsules per minute. This high throughput lets you produce over 10,000 pods in a single shift. This level of efficiency means you can consolidate multiple older, slower lines into one compact footprint, freeing up valuable floor space for your next growth phase.

How do you choose the right coffee packing machine?

You're worried about making a huge investment. A machine that is too slow will limit your growth, but one that is too complex will cause downtime and waste. You need a clear way to decide.

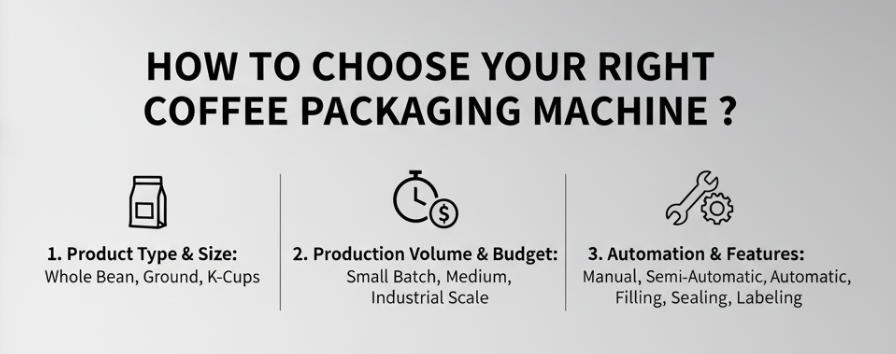

Focus on three key areas: speed (throughput), flexibility (changeovers), and accuracy (waste). Match these to your business goals. A high-speed VFFS is great for one main product, while a premade pouch machine offers flexibility for many different SKUs.

Choosing a machine is a balancing act. The fastest machine isn't always the best, and the cheapest machine is rarely the most cost-effective over its lifetime. I always advise my clients to think about not just where their business is today, but where they want it to be in five years. Let's look at the framework we use to help them make the right choice.

Throughput & Uptime?

Throughput is measured in bags per minute (bpm). A VFFS machine is generally faster, often reaching 60-80 bpm, while a premade pouch machine typically operates around 20-40 bpm. But speed is nothing without uptime. Look at Overall Equipment Effectiveness (OEE). A simpler, more reliable machine running consistently can outperform a faster but more complex one that stops frequently. If your goal is to produce huge volumes of a single bag style, VFFS is your winner. If you need to produce premium pouches, the slower speed of a premade machine is a necessary trade-off.

Changeover & SKU Complexity?

How many different bag sizes, coffee types, and designs do you run? If you have many SKUs, changeover time is critical. This is the time it takes to switch the machine from one product or bag to another. Some machines require extensive tool changes, while others feature tool-less adjustments. Premade pouch machines often excel here, as changing bag sizes can be as simple as adjusting the grippers. On a VFFS machine, changing bag width requires swapping out the entire forming tube, which takes more time. Easy changeovers mean less downtime and more production flexibility.

Accuracy & Waste?

This brings us back to the weigher. For whole beans, a quality multihead weigher can be accurate to within a gram. An auger for ground coffee is accurate by volume. Over a year, giving away just one or two extra beans per bag adds up to thousands of dollars in lost product. This is why investing in an accurate weighing system pays for itself. The machine's seal quality also impacts waste. Poor seals lead to leaky bags, wasted product, and unhappy customers. We build our Smart Weigh systems with precision weighers and reliable sealers to minimize this from day one.

Total Cost to Own?

The sticker price is just the beginning. The Total Cost of Ownership (TCO) includes the initial investment, tooling for different bag sizes, and the ongoing cost of materials. For example, rollstock film for a VFFS machine is significantly cheaper per bag than buying premade pouches. However, a premade machine might not require as much specialized tooling. You also need to factor in maintenance, spare parts, and labor. A low TCO comes from a machine that is reliable, efficient with materials, and easy to maintain.

What does a complete coffee packing line look like?

You bought a packing machine. But now you realize you need a way to get coffee into it and a way to handle the bags coming out. A single machine doesn't solve the whole problem.

A complete packaging system integrates multiple components seamlessly. It starts with an infeed conveyor to transport coffee to a weigher, which sits on a platform above the bagger. After bagging, downstream equipment like checkweighers and case packers finish the job.

I've seen many companies buy a bagger only to create a bottleneck in their production. The real efficiency comes from thinking about the entire line as one integrated system. A well-designed line ensures a smooth, continuous flow from your roaster to the final shipping case. As a full-system provider, this is where we shine. We don't just sell a machine; we design and build the entire automated solution for you.

Here is a breakdown of a typical line:

The Core Packaging System

Infeed Conveyor: A Z-bucket elevator or incline conveyor gently lifts your whole beans or ground coffee up to the weigher without causing damage or separation.

Weigher / Filler: This is the multihead weigher or auger filler we discussed. It's the brain of the accuracy operation.

Platform: A sturdy steel platform holds the weigher securely above the bagging machine, allowing gravity to do its work.

Bagger / Sealer: The VFFS, premade pouch, or capsule machine that forms/handles the package, fills it, and seals it shut.

Downstream and Quality Control

Take-away Conveyor: A small conveyor that moves the finished bags or pods away from the main machine.

Date Coder / Printer: A thermal transfer or laser printer applies the "best by" date and lot code.

Checkweigher: A high-speed scale that weighs every single package to ensure it is within your specified tolerance, rejecting any that are out of bounds.

Metal Detector: A final quality control step that checks for any metal contaminants before the product gets packed into a case, ensuring food safety.

Robotic Case Packer: An automated system that picks up the finished packages and places them neatly into shipping boxes.

Conclusion

Choosing the right coffee packing system is a journey. It requires matching your product, your bag, and your production goals to the right technology for long-term success and efficiency.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine