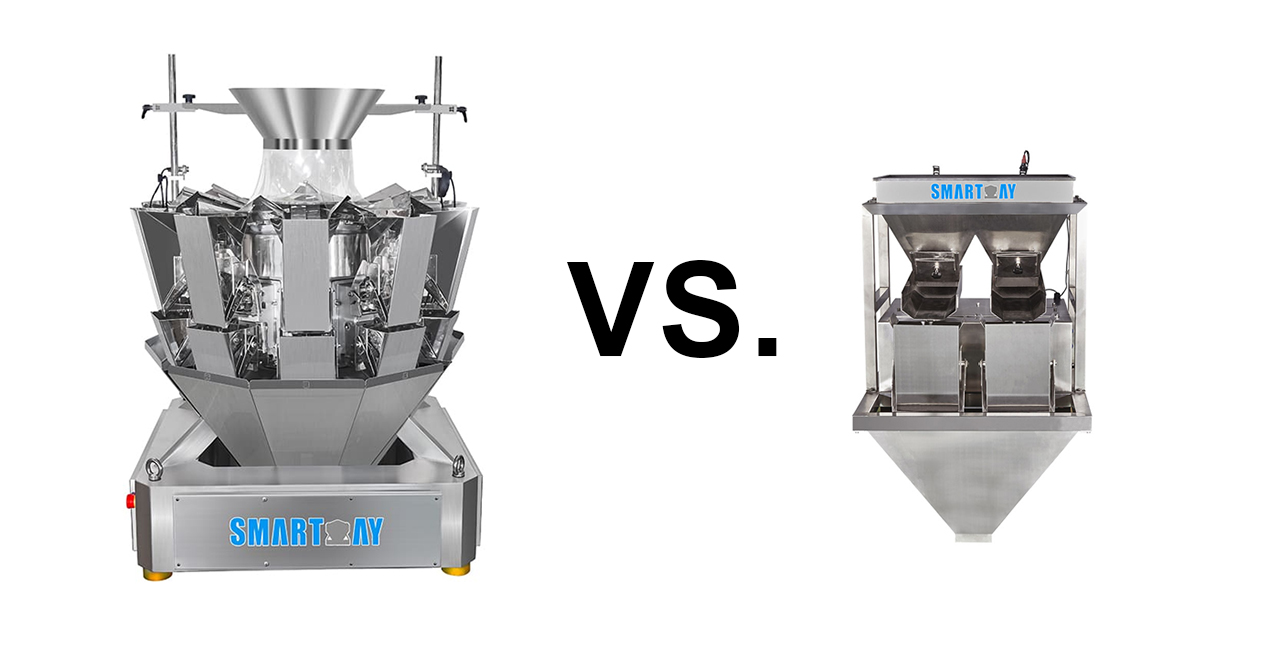

Multihead Weigher vs. Linear Weigher: Which Saves More Money?

Efficiency in the competitive manufacturing sector of today is about financial survival, not only about speed. Automated weighing systems represent one of the most critical investments for production facilities, directly impacting operational costs, product consistency, and ultimately, profitability. Choosing between multihead weighers and linear weighers isn't merely a technical decision; it's a strategic financial choice that can significantly affect your bottom line for years to come.

Consider this: According to recent industry studies, optimized weighing systems can reduce product giveaway by up to 80% compared to manual operations, potentially saving manufacturers hundreds of thousands of dollars annually. For a medium-sized food production facility, even a 1% reduction in overfilling can translate to substantial five-figure savings each year.

This comprehensive comparison explores the financial implications of both multihead and linear weighing technologies, examining not just the upfront investment but the total cost of ownership and long-term return on investment. Whether you're producing snack foods, confectionery, frozen vegetables, or non-food items, understanding these financial considerations will help you make an informed decision that aligns with your production needs and budget constraints.

Understanding Weighing Technologies

Multihead Weighers: How They Work

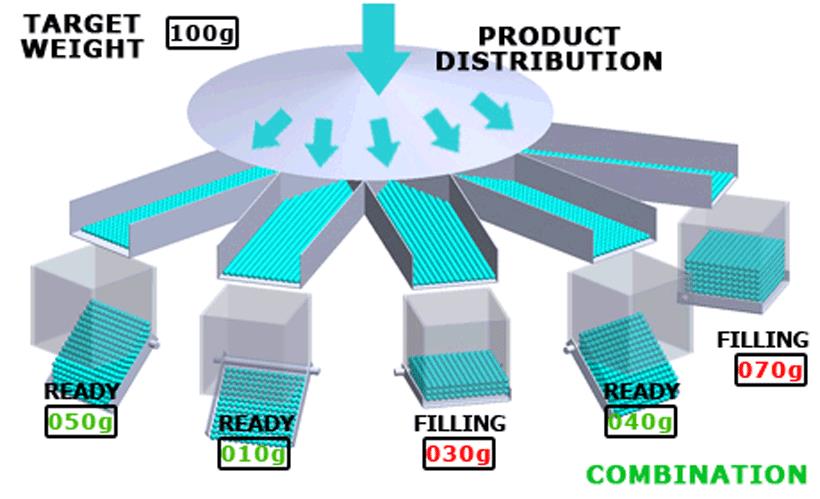

Multihead weighers (also called combination weighers) operate on a sophisticated principle of combinatorial mathematics. The system features multiple weighing heads arranged in a circular configuration, each containing a load cell that precisely measures product weight. Products are fed into a dispersion table at the top of the machine, which distributes the product evenly to vibrating radial feeders leading to each weighing hopper.

The system's computer simultaneously evaluates all possible combinations of hoppers to find the combination that comes closest to the target weight. Once identified, those specific hoppers open, dropping their contents into a collection chute that feeds the packaging machine below. This process happens in milliseconds, allowing for extremely high-speed operation.

Multihead weighers excel in handling a wide range of products including snacks, frozen foods, confectionery, grains, pet food, and even non-food items like hardware components. Recent technological advancements include improved user interfaces, remote monitoring capabilities, IP65-rated waterproof designs for thorough washdown, and intelligent self-adjusting systems that optimize performance based on product characteristics.

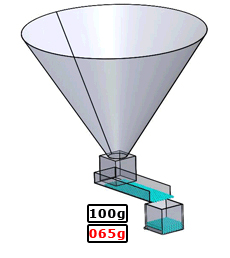

Linear Weighers: How They Work

Linear weighers utilize a more straightforward approach with product flowing along a single path. Products are typically fed via a vibratory conveyor or feeding system that meters product onto a lane or belt then into a weighing bucket. The system measures each individual portion before releasing it to the packaging stage.

The weighing process is sequential rather than combinatorial, with feedback mechanisms controlling the feed rate to achieve target weights. Modern linear weighers use sophisticated algorithms to predict final weights and adjust feeder speeds in real-time, improving accuracy.

These systems are particularly effective for applications requiring gentle handling, products with consistent piece sizes, or where simplicity of operation is prioritized. Industries commonly using linear weighers include produce, bulk materials, and single-piece items where individual weighing provides adequate throughput.

Initial Investment Comparison

Upfront Costs

Multihead weighers represent a significantly higher initial investment than linear systems. With multiple weighing heads, sophisticated control systems, and robust construction, these machines typically cost several times more than their linear counterparts. Installation and integration add approximately 10–15% to this cost, with potential facility modifications for height requirements and support structures.

Linear weighers are considerably more economical upfront, generally costing a fraction of multihead systems. Their simpler design and fewer components contribute to this lower entry price. Installation costs are generally lower as well, adding approximately 5–10% to the base price, with fewer facility modifications typically required due to their more compact footprint.

ROI timeline expectations differ significantly: multihead weighers typically require 18–36 months to recover costs through efficiency gains, while linear weighers may achieve ROI within 12–24 months due to lower initial investment, though with potentially fewer long-term savings.

Training and Operational Readiness

Multihead weighers require more extensive operator training due to their complex user interfaces and multiple configuration options. Staff typically need 3–5 days of formal training plus several weeks of supervised operation to become proficient. The learning curve is steeper, but modern interfaces have simplified operation considerably.

Linear weighers feature simpler operation with fewer variables to manage, generally requiring only 1–2 days of formal training. Operators typically achieve proficiency within a week. Implementation timeframes reflect this difference, with linear systems typically operational within days while multihead systems may require 1–2 weeks for full optimization.

Operational Cost Analysis

Production Speed and Output

The speed differential between these technologies is substantial. Multihead weighers deliver impressive throughput of 30–200 weighments per minute depending on the model and product, with some high-speed systems achieving even higher rates. This makes them ideal for high-volume production environments where maximizing output is critical.

Linear weighers typically operate at 10–60 weighments per minute, creating a significant capacity gap for high-volume operations. For facilities producing over 1,000 packages per hour consistently, this throughput difference can mean multihead technology is the only viable option despite higher upfront costs.

The efficiency advantage of multihead weighers becomes particularly evident in handling variable product sizes or mixed products, where their combinatorial approach significantly outperforms the sequential weighing of linear systems.

Energy Consumption

Multihead weighers consume more energy due to their multiple motors, drives, and computational requirements. A standard multihead system draws significantly more power during operation compared to linear systems, translating to higher annual power costs based on continuous operation.

Linear weighers typically require substantially less power, resulting in lower annual energy costs under similar operating conditions. This creates a modest but notable operational cost advantage for linear systems, though it's typically overshadowed by other financial factors in the total cost comparison.

Modern versions of both technologies have introduced energy-efficient features, including sleep modes during production pauses and more efficient motors, somewhat narrowing this gap.

Labor Requirements

Both systems reduce labor compared to manual operations, but with different staffing profiles. Multihead weighers generally require one skilled operator per line for monitoring and adjustment, with minimal intervention during stable production. Their automation level reduces the need for constant attention.

Linear weighers typically require similar base staffing but may need more frequent interventions for adjustments during production, potentially increasing labor costs by 10–15% compared to multihead systems in high-volume environments. For smaller operations running at lower speeds, this difference becomes negligible.

Product-Specific Considerations

Product Giveaway Analysis

Product giveaway—the excess product provided above the stated package weight—represents one of the most significant hidden costs in packaging operations. Multihead weighers excel in minimizing this cost through their combinatorial approach, typically achieving accuracy within 0.5-1.5 grams of target weight even at high speeds.

For context, a snack food manufacturer producing 100 tons of product monthly with a 3-gram average overfill would give away 3% of their product value. By reducing overfill to 1 gram using a multihead weigher, they could save approximately 2% of product value monthly—a substantial sum when calculated annually.

Linear weighers typically achieve accuracy within 2-4 grams of target weight, with performance varying based on product consistency. This difference might seem small, but for high-volume producers, the additional 1-3 grams per package represents significant annual product giveaway costs.

Product Versatility

Multihead weighers offer exceptional versatility, handling a wide range of products from small granular items to larger pieces, sticky products (with proper modifications), and mixed products. This adaptability makes them ideal for facilities producing multiple product lines or anticipating future diversification.

Changeover between products typically takes 15-30 minutes, including cleaning and parameter adjustments. Modern systems with recipe storage functionality can reduce this time further by saving optimal settings for each product.

Linear weighers excel with consistent, free-flowing products but face challenges with sticky or irregular items. They generally offer faster changeovers (10-15 minutes) due to simpler designs and fewer components requiring cleaning or adjustment. This advantage makes them attractive for facilities with limited product variety but frequent batch changes.

Long-Term Financial Impact

Maintenance Costs

Maintenance requirements represent a significant difference between these technologies. Multihead weighers have more components—including multiple load cells, motors, and hoppers—increasing maintenance complexity. Annual maintenance costs typically range from 3-5% of the initial system price, with preventative maintenance schedules including quarterly inspections and annual calibration.

Linear weighers, with fewer moving parts, generally incur annual maintenance costs of 2-3% of the initial price. Their simpler design means fewer potential failure points, though their vibratory feeding systems require regular attention to maintain accuracy.

Both systems benefit from service contracts, though the complexity of multihead systems makes professional maintenance support particularly valuable despite the higher service contract costs.

System Longevity

Quality automated weighing systems represent long-term investments with considerable longevity. Multihead weighers typically remain operational for 10-15 years or more with proper maintenance, with many manufacturers offering upgrade paths for control systems and software to extend functional lifespan. Their robust construction is designed for continuous operation in demanding environments.

Linear weighers generally offer similar longevity of 10-15 years, with their simpler mechanical systems sometimes providing an advantage in harsh environments. However, their technological capabilities may become limited compared to newer systems over time.

Depreciation schedules should reflect this long-term value, with most companies applying 7-10 year schedules for tax purposes.

ROI Case Studies

Small Production Facility Example

A small specialty nuts producer facing inconsistent package weights and excessive product giveaway evaluated both weighing technologies. With production volumes of approximately 30 packages per minute and multiple product variants, they needed flexibility without excessive capital investment.

After analysis, they implemented a small multihead weigher despite the higher initial investment. The results included:

● Reduction of overfilling from 4g to 1.2g per package

● Annual product savings equivalent to 2.8% of production volume

● Complete ROI achieved within 24 months

● Unexpected benefit of 15% overall line efficiency improvement due to consistent feeding to the packaging machine

Large-Scale Production Example

A large snack processor operating three high-volume lines needed to replace aging weighing equipment while improving efficiency. The company conducted a five-year cost analysis comparing both technologies across multiple factors.

Their analysis revealed that multihead technology provided superior long-term value based on:

● 2.5x higher production speed capability

● 65% reduction in product giveaway

● 30% reduction in labor costs for monitoring and adjustments

● Greater flexibility for handling their diverse product range

The five-year projection showed that despite the higher initial investment, the multihead solution would deliver approximately 40% better overall return on investment through operational savings.

Decision Framework

When to Choose a Multihead Weigher

Multihead weighers generally provide better financial returns under these conditions:

● Medium to high production volumes (>30 packages per minute)

● Irregular or difficult-to-handle products

● Mixed product requirements

● High-value products where giveaway costs are significant

● Multiple product lines requiring versatility

● Available capital for longer-term investment

● Facility expansion plans requiring future scalability

When to Choose a Linear Weigher

Linear weighers often represent the more economical choice when:

● Production volumes are lower (<30 packages per minute)

● Products are consistent in size and flow easily

● Budget constraints limit initial investment capability

● Space limitations exist within the facility

● Single-product focus with limited variation

● Gentle handling is required for delicate products

● Simplicity of operation is prioritized over maximum precision

Implementation Best Practices

Maximizing ROI with Proper Setup

Regardless of the technology selected, optimizing setup dramatically impacts financial returns:

Proper system sizing: Avoid over-specification by carefully matching capacity to actual production needs with reasonable headroom for growth.

Integration optimization: Ensure seamless communication between the weigher and packaging machine to prevent start-stop inefficiencies that reduce overall line efficiency.

Performance monitoring systems: Implement real-time monitoring to track key metrics including:

● Actual vs. target weights

● Production speed

● Downtime causes

● Efficiency metrics

Validation protocols: Establish regular validation procedures to maintain accuracy and prevent drift in weighing performance over time.

Avoiding Common Costly Mistakes

Several critical errors can undermine the financial benefits of weighing system investments:

Over-specification: Purchasing excessive capacity or unnecessary features adds cost without proportional return.

Maintenance neglect: Skipping recommended maintenance schedules leads to decreased accuracy, higher giveaway costs, and premature component failure.

Insufficient training: Inadequate operator training results in suboptimal settings, increased downtime, and higher product giveaway.

Poor product flow management: Failure to optimize product delivery to the weighing system creates inconsistent weighments and reduced accuracy.

Improper installation: Vibration, electrical interference, or environmental factors can compromise weighing accuracy if not properly addressed during installation.

Conclusion

The choice between multihead and linear weighers represents a significant financial decision with implications extending far beyond the initial purchase price. For high-volume operations, products with challenging characteristics, or facilities requiring versatility, multihead weighers generally deliver superior long-term financial returns despite higher upfront costs. Their precision, speed, and adaptability create ongoing operational savings that compound over time.

Conversely, linear weighers provide a cost-effective solution for operations with lower volumes, consistent products, or budget constraints. Their simpler design and lower entry cost make them appropriate for many small to medium-sized manufacturers or specialized applications.

The optimal decision requires a comprehensive analysis of your specific production requirements, product characteristics, and financial parameters. By carefully evaluating these factors and considering the total cost of ownership rather than just initial price, you can select the weighing technology that will deliver the greatest financial benefit to your operation over time.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine