Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

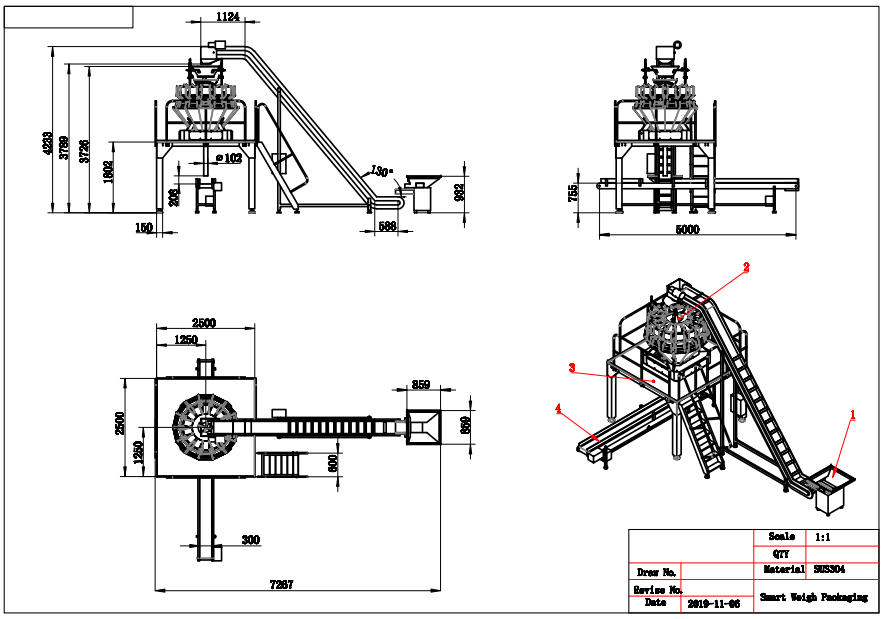

Long screw into carton weighing and packing machine

Widely applying in the hardware industry, this weigher is appropriate for weighing products such as screws, nails, metal parts and etc.

Highly effective screw weighing and packing line from Smart Weigh helped a Colombian manufacturer of machinery cut production time and expenses and boost profit margins.

1. Wear resistant

For weighing nail/screw ,normal thickness weigher machine hard to stand the big impact thus Smartweigh design a strengthen weigher for a longer service life to weighing big nail/bolt/screw/hardware.

Top cone pan: 3.0mm

Feed hopper: 2mm thickness + 3mm strengthen on the door

2. Save labor

Initially, the firm had to hire 50 workers to physically weigh and pack screws, but by using the multi-head weighers that Smart Weigh offered, they were able to complete the task with just 10 personnel.

Only two personnel are needed to operate a single packing line thanks to the weighing and packaging system, which automatically weighs, feeds, and delivers the entire process. This greatly lowers labor expenses.

3. Flexible choice

Depending on the cost and labor force, you can alternatively select a fully or a semi-automatic box packing method. According to varied nail lengths and box sizes, you can select several models of weighing and packing machine.

1.The thickened hopper is not easy to be worn by iron nails and has a long service life.

2. Multihead weigher automatic weighing and combining ,selecting the most premium target weigh to reduce giveaway.

3.High precision, low packaging failure rate, less screw waste and low production cost.

4.Different size and mechanism of the machine to meet different materials .

5. Capable to weighing chemical product in small weight such as cannabis and tablet.

6. Counting and weighing mode are available for weighing different characteristic material.

8.Different hoppers have different sizes and types according to the characteristics of different materials.

9.Multi-head weighing machine made of SUS304 stainless steel that has strong impact resistance, a large hopper thickness, and good stability performance.

Nail size

Length | Diameter |

12 mm | 0.88 mm |

16 mm | 1 mm |

9 mm | 1.2 mm |

25 mm | 1.65 mm |

32 mm | 1.8 mm |

38 mm | 2.1 mm |

45 mm | 2.4 mm |

Box size

Length | width | height | Weigh |

8 cm | 5 cm | 12 cm | 1 kg |

12cm | 12cm | 17 cm | 5 kg |

Model | SW-M14 |

Weighing Range | 10-2000 grams |

Max. Speed | 120 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 12A; 1500W |

Driving System | Stepper Motor |

Packing Dimension | 1720L*1100W*1100H mm |

Gross Weight | 550 kg |

bbg

Smart Weight provides you with an ideal weighing and packaging solution. Our weighing machine can weigh particles, powders, flowing liquids and viscous liquids. The specially designed weighing machine can solve the weighing challenges. For example, the multi head weigher with dimple plate or Teflon coating is suitable for viscous and oily materials, the 24 head multi head weigher is suitable for mixture flavor snacks, and the 16 head stick shape multi head weigher can solve the weighing of stick shape materials and bags in bags products. Our packaging machine adopts different sealing methods and is suitable for different bag types. For example, vertical packaging machine is applicable to pillow bags, gusset bags, four side seal bags, etc., and the premade bag packaging machine is applicable to zipper bags, stand up pouches, doypack bags, flat bags, etc. Smart Weigh can also plan the weighing and packaging system solution for you according to the actual production situation of customers, so as to achieve the effect of high precision weighing, high efficiency packing and space saving.

How does the customer check the quality of the machine?

Before delivery, Smart Weight will send you photos and videos of the machine. More importantly, we welcome customers to check the operation of the machine on site.

How does Smart Weight meet customer requirements and demands?

We provide customized services for you, and answer customers' questions online 24 hours at the same time.

What is the payment method?

Direct telegraphic transfer through bank account

L/C at sight.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved