Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Why choose for a bag-in-bag automated secondary packaging system?

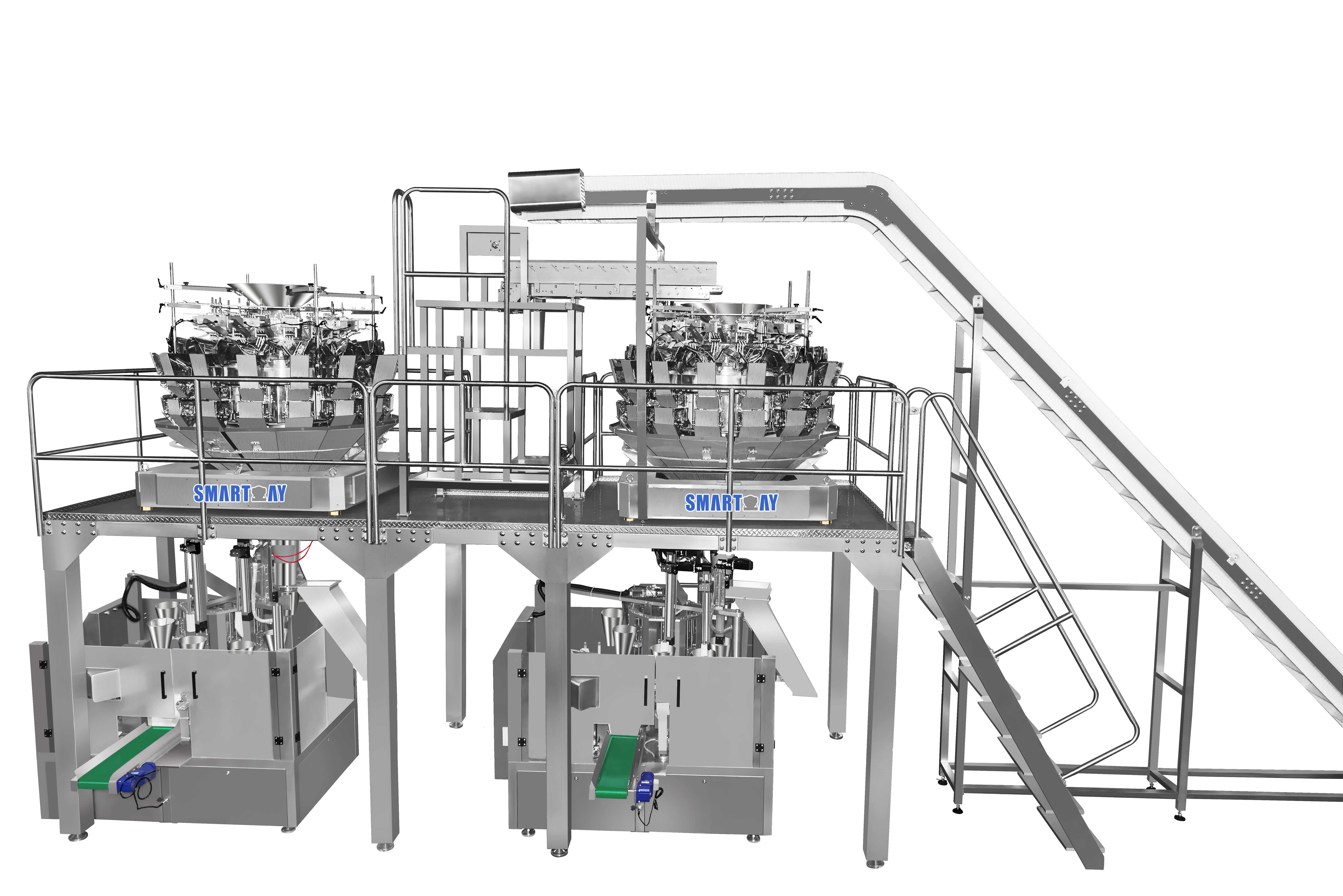

Smart Weigh was contacted by a customer from Australia who needed a solution for automatic bag-in-bag weighing and packaging. Most of the cooked meat products produced by this client are beef tendons and duck necks, which are packaged in tiny bags into large bags. An automatic multi-functional bag-in-bag secondary packing line, provided by Smart Weigh, is capable of automating the entire process of automatic weighing and counting, secondary packaging and sealing. With a 0.1 g precision, it can complete 120 bags every minute (120 x 60 minutes x 8 hours = 57,600 bags/day).

This customer later provided us with positive feedback, stating that only 1-2 workers are required to operate a bag in bag packaging machine, significantly reducing labor costs. The production efficiency has doubled compared to the initial hand packaging.

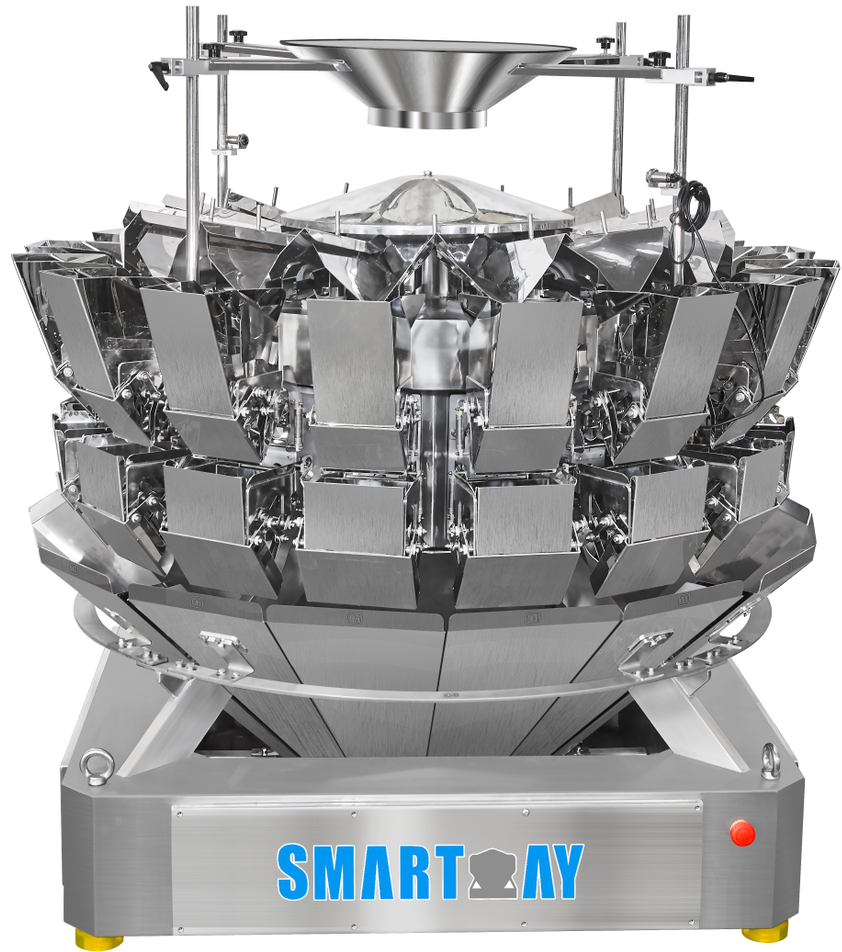

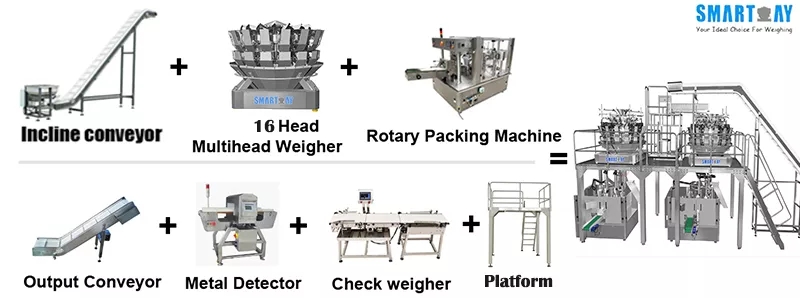

The automatic bag-in-bag snack filling system is integrated with a 16-head weigher, a pre-made bag packing machine, an inclination conveyor, an output conveyor, a support platform, and other components.

It can optionally be fitted with a check weigher to confirm the weight and a metal detector to prevent bags containing metal from being accepted.

Weighing machine for a variety of sectors, for weighing granular materials, including cereals, nuts, puffed snacks, frozen raw meat and seafood, vegetables, fruits, and small bags of products like beef tendons, baked gluten, duck necks, chicken claws, and frozen raw meat and shellfish. Also capable of weighing tablets, screws, and nails.

Model | SW-M16 |

Weighing Range | 10-2500 grams |

Max. Speed | 120 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket Volume | 3.0L |

Control Penal | 7" or 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 12A; 1500W |

Driving System | Stepper Motor |

Packing Dimension | 1780L*1230W*1435H mm |

Gross Weight | 600 kg |

* Improved filling and dividing methods for secondary packaging of small bags, making each hopper more evenly filled and improving speed and precision.

* Special optimized program for dual use of points and weighing modes.

* V-shaped line vibrating plate design for better effect on small quantities of packaging.

* Weighing detection auxiliary feeding system to meet the needs of different materials.

* All food contact parts can be disassembled without tools, which facilitates daily cleaning work.

* Automatic adjustment of weighing according to the overweight/light signal of the selection scale to meet the requirements of high precision.

* Stepper motor opening angle can be adjusted to meet different material requirements;

* Increase the forced passage to avoid overweight/overlight materials from entering the bag, reducing consumables and waste.

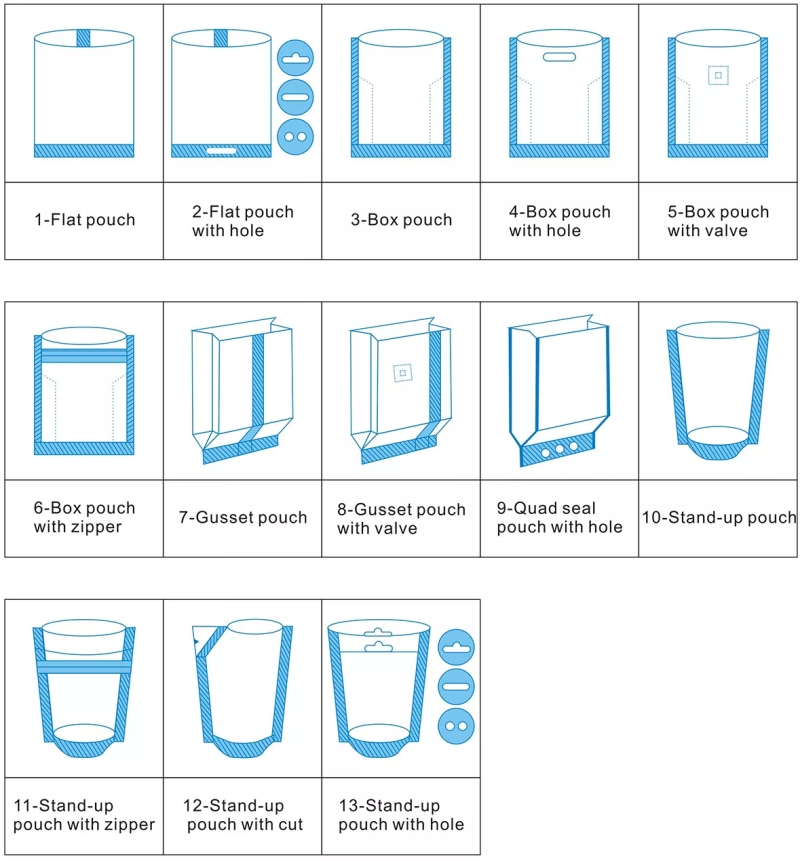

All types of bags, including stand-up pouches, zipper-lock bags, organ bags, heated four-sided bags, etc. can be packed using a machine designed for pre-made bags. For packing, materials composed of plastic or paper, single-layer PE, PP, and multi-layer laminated film are acceptable.

1. The speed of machine operation can be adjusted by frequency conversion speed control device according to the characteristics of the material and the needs of production.

2. The size of bags and the width of clips can be flexibly adjusted according to the customers' requirements.

3. Pre-made pouch bag shape is more beautiful.

4. CE quality certification, the machine runs smoothly and has a long service life.

5. Easy to operate, equipped with touch screen and electric control system, friendly human-machine interface.

6. Automatic checking, no filling and no sealing when there is no bag or wrong bag opening.

7. Machine stop when air pressure is abnormal, heater disconnection alarm.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425