Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

To replace the manual weighing and packaging techniques of the past, many manufacturers of spices, flour, starch, laundry, coffee, coconut, and wheat flour turn to Smart Weigh for automation powder weighing and packaging machines. Our weighing and packaging equipment is very effective, cuts down on manufacturing time, and is highly accurate to lower weighing errors.

We often advise the closed screw feeder and auger filler for the weighing of easily volatile powders because they can effectively stop material leakage and ensure workplace hygiene. For high precision metering, auger fillers operate by continuously spinning and churning the powder. Different screw sizes can be matched with the packaging machine and are suitable for different weights.

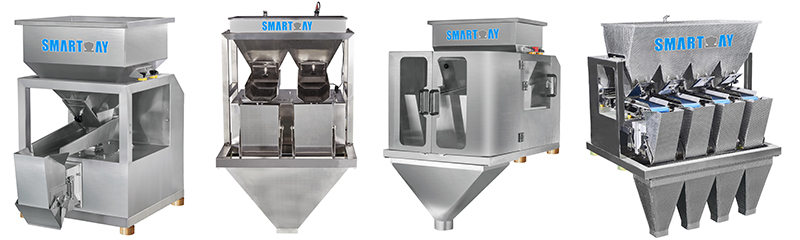

In order to weigh non-volatile particles, linear weigher is advised, cheaper, simpler, safe and hygienic structure composed of SUS304 stainless steel. Linear weigher is easy to use and achieves automatic weighing using the vibration of the linear pan. Customers can select 1/2/3/4 heads linear weighing machines, depending on their demands.

Model | SW-LW1 | SW-LW2 | SW-LW3 | SW-LW4 |

Single Dump Max. (g) | 20-1500 G | 100-2500 G | 20-1800 G | 20-1800 G |

Weighing Accuracy(g) | 0.2-2g | 0.5-3g | 0.2-2g | 0.2-2g |

Max Weighing Speed | + 10wpm | 10-24wpm | 10-35wpm | 10-45wpm |

Weigh Hopper Volume | 2500ml | 5000ml | 3000ml | 3000ml |

Control Penal | 7" Touch Screen | 7" Touch Screen | 7" Touch Screen | 7" Touch Screen |

Max. mix-products | 1 | 2 | 3 | 4 |

Power Requirement | 220V/50/60HZ 8A/800W | 220V/50/60HZ 8A/1000W | 220V/50/60HZ 8A/800W | 220V/50/60HZ 8A/800W |

Packing Dimension(mm) | 1000(L)*1000(W)1000(H) | 1000(L)*1000(W)1000(H) | 1000(L)*1000(W)1000(H) | 1000(L)*1000(W)1000(H) |

Gross/Net Weight(kg) | 180/150kg | 200/180kg | 200/180kg | 200/180 kg |

Cheap, compact, and able to produce simple and effective packaging, vertical packaging machines can be used to create 8 or 10 chain bags, quad bags, pillow bags, and bags with pillow gussets, among other types of bags. With a packing speed of roughly 40 bags per minute, vertical form-fill-seal machine is ideal for small workplaces. It integrates feeding, weighing, date coding, and bag sealing in one device. For packing stick powder, you can alternatively select a multi-column vertical packaging machine.

Rotary packaging machines are ideal for pre-made bag packaging with exquisite look, such as doypack bags, stand-up bags, zipper bags, flat bags, etc. The machine can alter the width of the clips according to the size of the bag. According to their needs, customers can select a single station/double station/eight station premade bag packing machine.

Fine particles with irregular forms can be packed using a powder packing line, including milk powder, monosodium glutamate, salt, detergent, medicinal powder, chili powder, etc.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved