Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Vertical packaging machine system, equipped with multihead weigher, metal detection & check weigher and labeling machine, can automatically complete weighing, bag forming, filling, sealing, cutting, labeling, and remove products containing metal, underweigh or overweight products.

Vertical packaging machine, suitable for making pillow bags and gusset bags, using roll film forming, automatic cutting and sealing.

Multi head weighing machine, suitable for granular materials, such as nuts, snacks, cereals, etc.

Model | SW-PL1 |

System | Multihead weigher vertical packing system |

Application | Granular product |

Weigh range | 10-1000g (10 head); 10-2000g (14 head) |

Accuracy | ±0.1-1.5 g |

Speed | 30-50 bags/min (normal) 50-70 bags/min (twin servo) 70-120 bags/min (continuous sealing) |

Bag size | Width=50-500mm, length=80-800mm (Depends on packing machine model) |

Bag style | Pillow bag, gusset bag, quad-sealed bag |

Bag material | Laminated or PE film |

Weighing method | Load cell |

Control penal | 7” or 10”touch screen |

Power supply | 5.95 KW |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ, single phase |

Packing size | 20”or 40”container |

14 heads multihead weigher

Features

l IP65 waterproof, use water cleaning directly, save time while cleaning;

l Modular control system, more stability and lower maintenance fees;

l Production records can be checked at any time or download to PC;

l Load cell or photo sensor checking to satisfy different requirements;

l Preset stagger dump function to stop blockage;

l Design linear feeder pan deeply to stop small granule products leaking out;

l Refer to product features, select automatic or manual adjust feeding amplitude;

l Food contact parts disassembling without tools, which is easier to clean;

l Multi-languages touch screen for various clients, English, French, Spanish, etc.

Vertical packing machine

Application

Suitable for many kinds of measuring equipments, and film in roll forming and sealing, mainly for food and non-food industry, such puffy food, , peanut, popcorn, cornmeal seed, sugar, nails and salt etc.

Features

l Mitsubishi PLC control system, more stable and accuracy output signal, bag-making, measuring, filling, printing, cutting, finished in one operation;

l Separate circuit boxes for pneumatic and power control. Low noise, and more stable;

l Film-pulling with servo motor for precision, pulling belt with cover to protect moisture;

l Open door alarm and stop machine running in any condition for safety regulation;

l Film centering automatically is available (Optional) ;

l Only control touch screen to adjust bag deviation. Simple operation;

l Film in roller can be locked and unlocked by air, convenient while change film;

Function

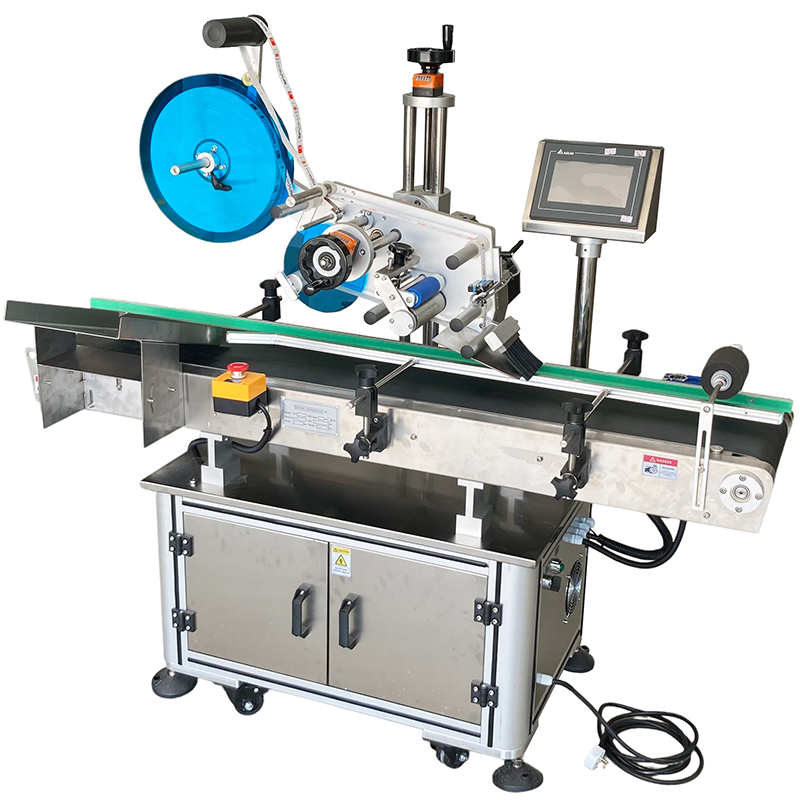

1. It can label for any products with flat surface. More flexible arrangement for manufacturing schedule.

2. The labeling head convenient to adjust, the labeling speed is automatically synchronous with the conveyor belt speed to ensure precise labeling.

3. The speed of conveyor line, the speed of pressure belt and the speed of label output can be set and changed by the PLC human interface.

4. Use famous brand PLC, stepping or servo motor, driver, sensor, etc, good quality components' configuration.

5. Different labeling solutions for flat surface, round labeling, taper wraping labeling can be supplied. One product can accomplish one sticker, two stickers or more stickers labeling, also can one sticker to finish one side, two sides, three sides or more sides labeling.

6. We can supply you the optional rotary table bottle unscrambler machine, which can be connected directly before the labeling machine, the operators can put the bottles on the rotary table, then the rotary table will send the bottles to the labeling machine to the labeling machine automatically.

7. It also can match with weight checker, metal detector, bottle filling machine, capping machine, can seaming machine, cover impressing machine, inkjet /laser / TTO printer etc.

Application

Flat surface plane labeling machine can work for all kinds of objects with plane, flat surface, side surface or large curvature surface such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc.Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries. It has optional date coding device, realize date coding on stickers.

Feature

1.Share same frame and rejector to save space and cost;

2.User friendly to control both machine on the same screen;

3.Various speed can be controlled for different projects;

4.High sensitive metal detection and high weight precision;

5.Reject arm, pusher, air blow etc reject system as option;

6.Production records can be downloaded to PC for analysis;

7.Reject bin with full alarm function easy for daily operation;

8.All belts are food grade & easy disassemble for cleaning.

It is suitable to detect various package include metal or not, and its weight qualify or not.

Guangdong Smart weigh pack integrates food processing and packaging solutions with more than 1000 systems installed in more than 50 countries. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, salad weighers, nut blending weighers, legal cannabis weighers, meat weighers, stick shape multihead weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle filling machines, etc.

In an era of the credibility crisis, trust needs to be earned. That is why I would like to take this chance and walk you through the journey of our past 6 years, That is why I would like to take this chance and walk you through the journey of our past 6 years, hoping to draw a clear picture of who this Smart Weigh, also your would-be business partner is.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved