Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

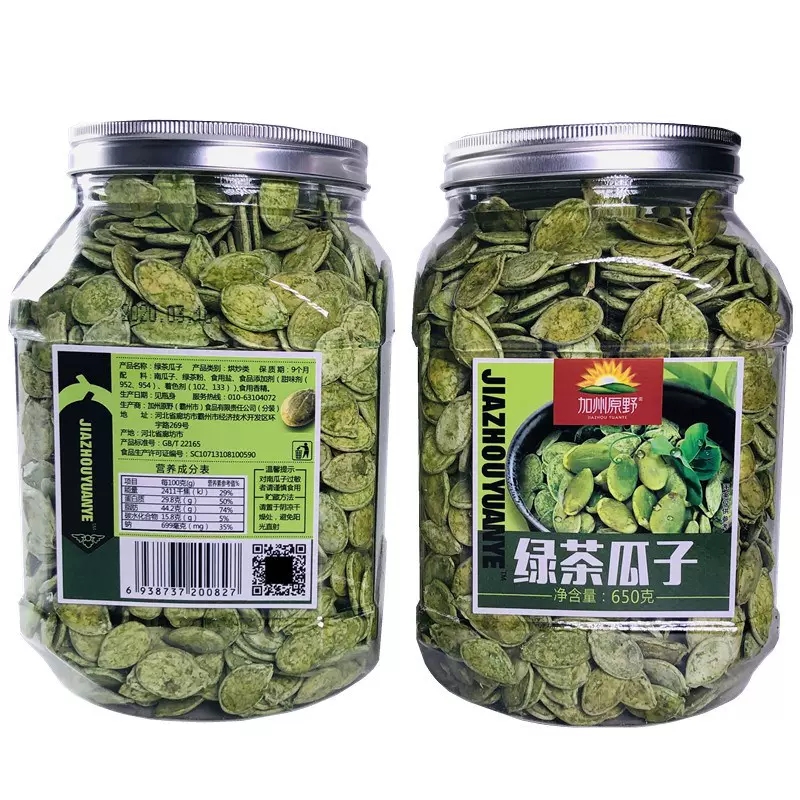

Thanks to bottle packaging lines, snacks can be better stored in great looking glass plastic bottles, jars and good sealing also helps to increase the shelf life of the food. As the food industry grows, more and more manufacturers are looking for high quality bottle filling and sealing machines for ambient or frozen storage of food products.

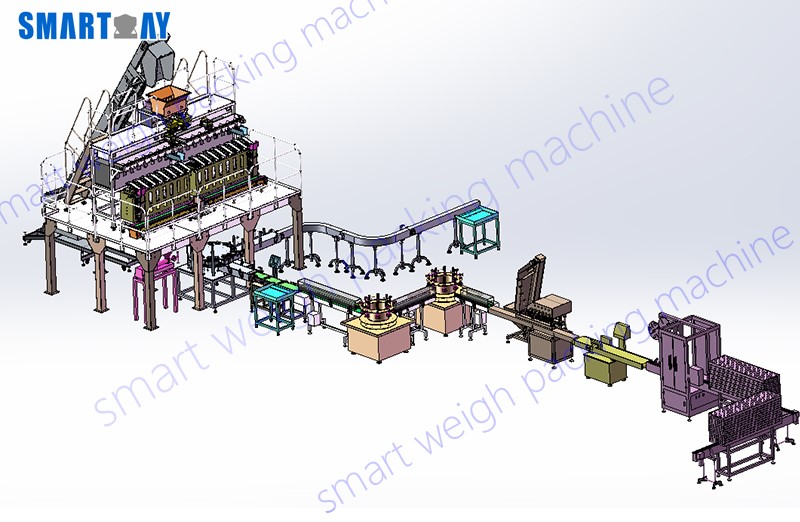

For different material characteristics, Smart Weigh has designed several bottle packaging systems for customers to choose freely.

Automatic pickle bottle packaging system, can finish 30 bottles per minute, (30x60 minutes x 8 hours = 14,400 bottles/day). Equipped with double layer filling machine, washing machine for rinsing jars, drying machine, bottle feeding machine, shrinking machine, capping machine, labeling machine, etc., it can guarantee the food hygiene in the packaging process.

Product | Korean Kimchi pickle |

Target weight | 300/600g/1200G |

Accuracy | +-15g |

Package Way | Bottle/jar |

Speed | 20-30 bottles per minute |

Suitable for bottling sticky materials such as kimchi, pickles and preserves.

The tin can packaging machine can pack 60 cans per minute (60x60 minutes x 8 hours = 28,800 bottles/day) with an accuracy of 0.1g and consists of a pellet filling head, a chain plate conveyor and a positioning device.

Weighing range | 10-1500g 10-3000g |

Weighing accuracy | 0.1-1.5g 0.2-2g |

Max filling speed | 60cans/min |

Hopper capacity | 1.6L/2.5L |

Power supply | AC220V 50/60Hz |

Machine size | L1960*W4060*H3320mm |

Weight | 1000kg |

Machine power | 3 kw(about) |

Control System | MCU |

Touch screen | 7 inches |

1. Seaming rollers are made of stainless steel with high hardness and never rusty with excellent sealing performance.

2. Electric appliance parts all use brand high end elements with reliable and steady performance.

3. Latest generation design of can steamer is non rotation of can body in the process of sealing, which avoids shift and scatter of product put well in the can.

4. The machining precision is high. Whole stainless steel materials are adopted for main part to design and manufacture which conforms to design requirements of manufacturing workshop.

The machine is suitable for high precision packaging of powder and irregular small granular materials, glucose, spices, toner, pesticides, rice, dried fruits, cookies, wolfberries, etc.

Servo-driven powder auminum tin sealing machine achieves 25-50 cans per minute (25-50x60 minutes x 8 hours =12000-24000 bottles/day), mainly applied to sealing paper cans, aluminum cans, iron cans and other round cans.

NAME | Technical Parameters |

Model | 130G |

Sealing Head | 1 |

Sealing Speed | 25-50cans/min(adjustable) |

Sealing Height | 50-230mm (shall be customized in case of exceeding 200mm)[adjustable] |

Can Diameter | 35-130mm |

Working Voltage | 220V 50/60HZ |

Electricity Power | 1300W |

Weight | 600KG |

Control module | PLC and touch screen |

Source gas | 0.6MPa |

Power | 1.1KW |

Dimension | 3000(L)*900(W)*1800(H)mm(including 2m conveyer belt) |

There are four seaming rollers around the chuck, which are made of chrome steel material with high hardness that will not rust, firm and durable.

Reasonable can design is used for the seam, which is firmly sealed and processed with high precision.

Automatic bottle packing machine with feeding, capping and labeling functions, suitable for packing granular materials, such as melon seeds, nuts and other puffed snacks.

How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own.

How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

What after-sales service will we provide?

15 months warranty.

Old machine parts can be replaced no matter how long you have bought our machine.

Oversea service is provided.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved