Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

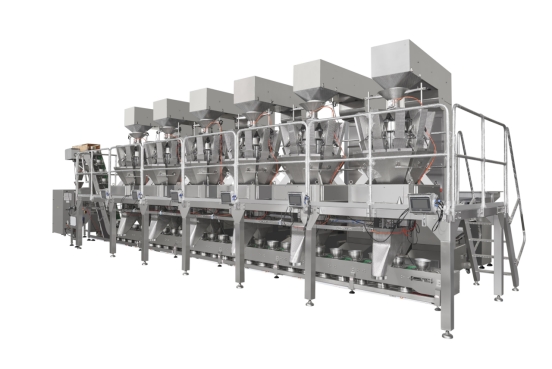

A Mexican customer who primarily manufactures mixed-flavor bottled fudge was previously packing by manual, which was very inefficient and the weight of each snack bottle was not well controlled. So Smart Weigh suggested to him a 32-head weigher, which substantially enhanced the packaging efficiency and accuracy.

The weighing of mixed flavor fondant faces two major challenges: the weighing accuracy of mixed materials is not well controlled, and sticky materials tend to adhere to the machine.

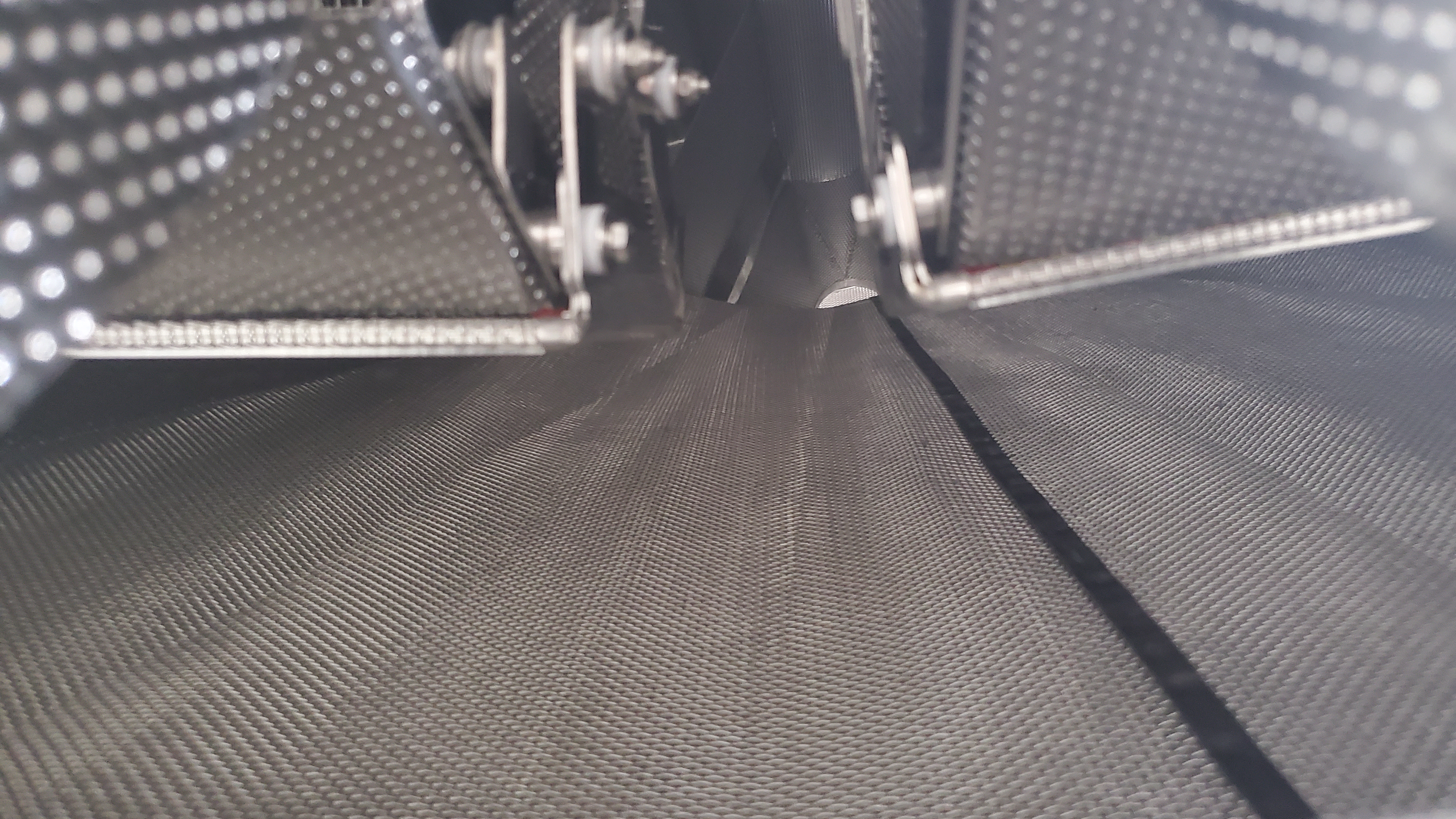

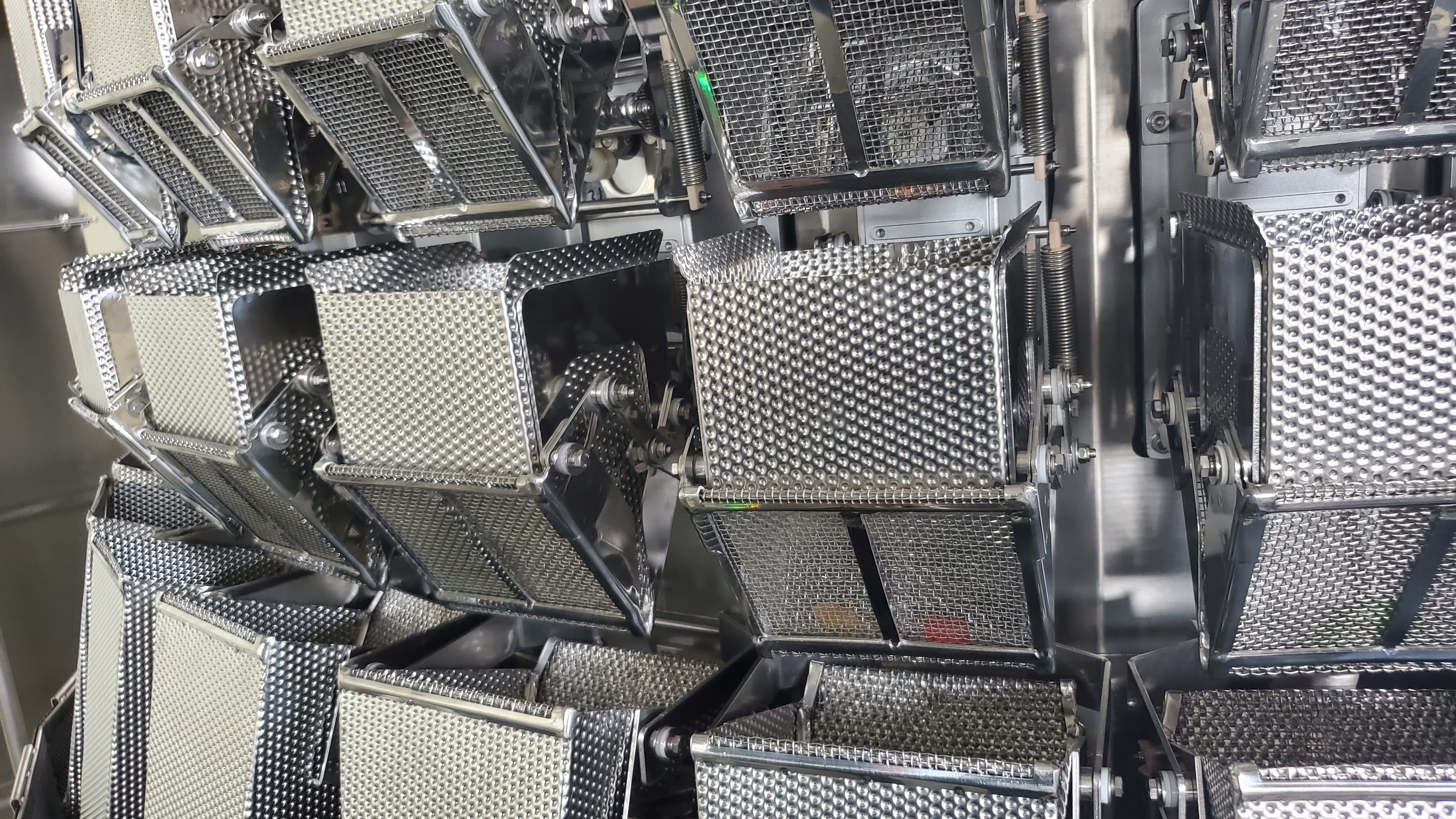

As a result, Smart Weigh designed a special mixed materials multi-head weigher with a mesh structure for all parts in contact with food, which effectively prevents material sticking.

With the compensation function, the total weight is precisely controlled by adjusting the percentage of each material.

Waste can be reduced by using rejection systems that discharge and recycle waste.

1. Mixing 4 or 6 kinds of product into one bag with high speed (Up to 50bpm) and precision

2. 3 weighing mode for selection: Mixture, twin & high speed weighing with one bagger;

3. Discharge angle design into vertically to connect with twin bagger, less collision & higher speed;

4. Select and check different program on running menu without password, user-friendly;

5. One touch screen on twin weigher, easy operation;

6. Central load cell for ancillary feed system, suitable for different product;

7. All food contact parts can be took out for cleaning without tool;

8. Check weigher signal feedback to auto adjust weighing in better accuracy;

9. PC monitor for all weigher working condition by lane, easy for production management;

10. Optional CAN bus protocol for higher speed and stable performance.

32 head weighing machine, mostly used for bulk mixed flavor snacks, irregular small granular materials, such as mixed candy, nuts, grains, etc.

For weighing mixed flavored snacks, you can also choose this high-speed and high-precision automatic weighing and packaging machine for 6 kinds of mixed confectionery with a speed of up to 35 bags/minute (35 x 60 minutes x 8 hours = 16,800 bags/day), and the weight of the final mixture can be controlled within 1.5-2g.

1. What is a modular control system?

Modular control system means board control system. The main board calculates as the brain and the drive board controls the machine work. Smart weighing multihead scales use a 3rd modular control system. The driver board controls 1 feed hopper and 1 secondary hopper. If 1 hopper is damaged, disable this hopper from working on the touch screen. The other hoppers can work as usual. And the drive board is common in the Smart Weighing series multihead weighers.

2. Does this scale only weigh 1 target weight?

It can weigh different weights by simply changing the weight parameter on the touch screen. It is easy to operate.

3. Is this machine made of stainless steel?

Yes, the machine structure, frame and food contact parts are made of food grade stainless steel 304, as our certificate proves.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved