Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

In the 1970s, the Japanese Agriculture Association put forward the weighing topics of the weighing instrument companies. In Japan, green peppers are usually sold in supermarkets in the form of bags. If the quantitative value per bag is 120g, it is a very difficult thing to print 120G. Due to the weight of a single green pepper, it is relatively related to consumer interests, and has a lot of costs related to enterprises. The traditional way is the amount of labor, that is, in a static electronic, it is called, a green pepper is accumulated to 115g, and then I want to find a 5G heavy green pepper and almost impossible, then you must be from 115g Take a smaller green pepper, add another bigger green pepper. If the weight is larger than 120g or less than 120g, it is also necessary to repeat the above working, which is extremely low, and it is difficult to achieve the result of approaching the target weight (quantitative value). After a large number of investigating studies on this, the technicians successfully solved the above-mentioned green pepper weighing problem using the combined weighing principles.

As the name suggests, multihead weigher machine has many "heads", in fact, "weigh the fight", divided into 8 buckets, 10 buckets, 12 buckets, 16 buckets, 20 fights, 16 buckets , 24 buckets, etc. According to the use environment type, the multihead weigher machine is also divided into waterproof type, rust-resistant, anti-collision type, general purpose, etc., is adopted by food packaging, daily chemical, tobacco, hardware (granules) industry. Divided into double open door, large column, double-crockery, low noise single-door type.

Multihead weigher machines come in various types, each designed to suit different production needs and product characteristics. Understanding the different types can help you choose the most appropriate machine for your specific requirements. Here are the main types of multihead weigher machines:

This is the most common shape of multihead weigher, it is consisted of feed hoppers, weigh hoppers and discharge chute, controlled by modular board with touch screen. Multihead weighing machines are widely used in snack food, chips, candy, cereals, meat, vegetables, and more products even the screws and nails. At the same time, they are quite flexible to equip with many kinds of packaging machines, such as vertical form fill seal machine, pouch packing machine, vacuum packing machine, thermoforming packaging machines, tray packing machine and more.

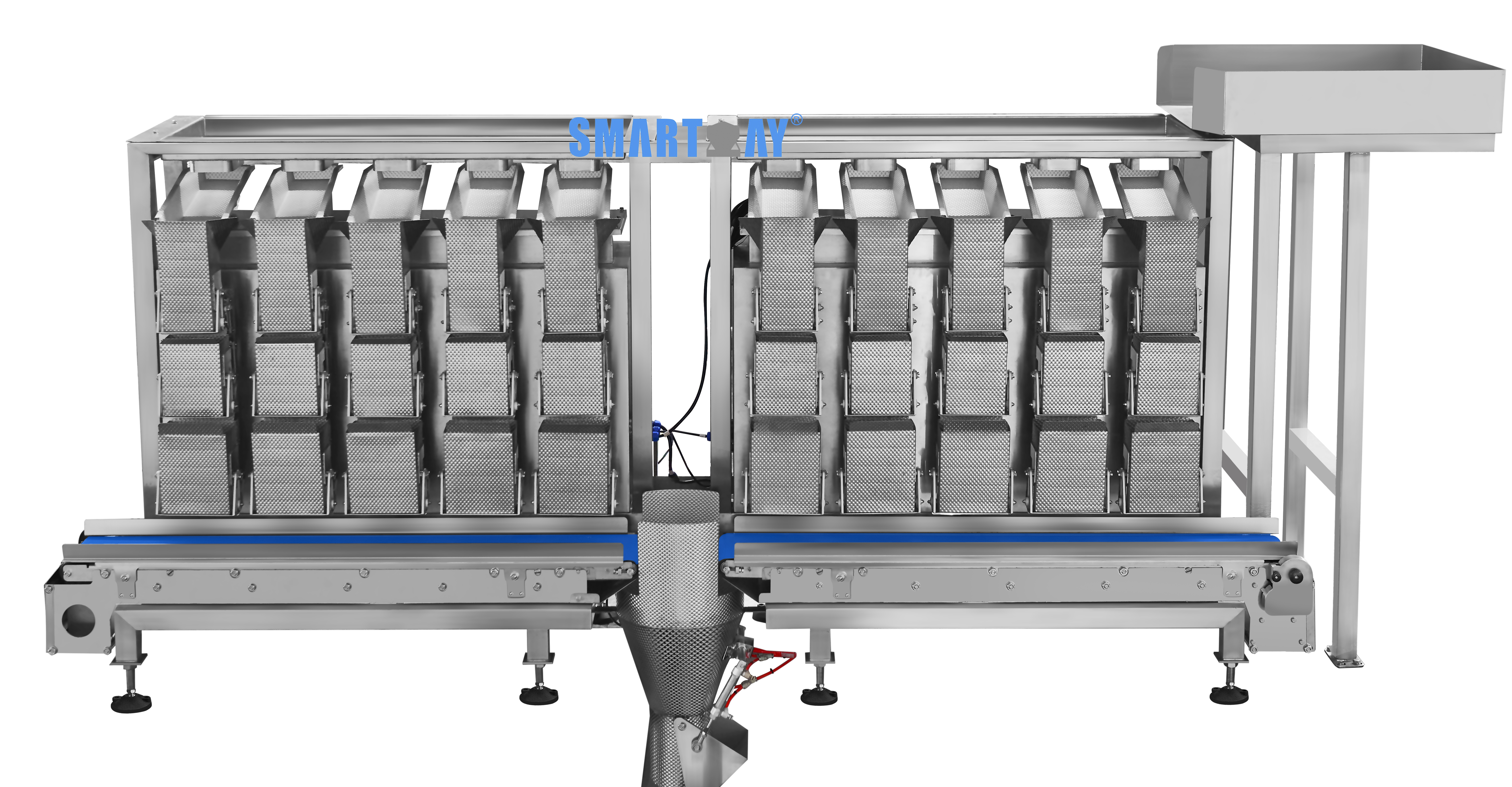

In Smart Weigh, the straight type of multihead weigher is called by linear multihead weigher. This shape of weigher is designed for sticky products, such as meat. It is consisted of scraper type feed and weigh hoppers, food grade PU collection belt, to minimize the stickiness of the product while weighing and filling.

Our standard linear combination weigher type, the typical model SW-LC12, is made for sticky items. It operates on the same principles as multihead weighers, and one benefit is that it covers a smaller area than other multihead weighers. Even though it requires manual feeding, it did not prevent him from becoming a best-selling machine in Europe.

While these three types of multihead weigher machines cover the majority of options available in the market, it's worth noting that manufacturers may offer variations or hybrid designs that combine features from different types. When selecting a multihead weigher machine, it's essential to consider the specific requirements of your product and production processes to choose the most suitable type for your needs.

As a multihead weigher manufacturer with 12 years experience, Smart Weigh has a deep understanding of the market and rich experience in providing the best multi head weigher pacakging machine solutions covering a wide range of industries, including snacks, ready to eat meals, fruits and vegetables, meat, bag-in-bag products, and even non-food products such as screws and hardwares.

Let's share your details with requests at export@smartweighpack.com, our professional sales team will assistant you find the best automatic packaging solution!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved