Wake wazibuza ukuthi imishini yokupakisha yamantongomane ikusiza kanjani ekupakisheni okulula, kanye nokugcinwa kwekhwalithi? Lokhu kungenxa yokuthi inqubo ukusuka ekushayweni kuya ekupakisheni okuphelele kungaba nzima kakhulu kwesinye isikhathi.

Lesi sihloko sixoxa ngemishini yokupakisha amantongomane kuyilapho sinikeza amathiphu athile awusizo ukusiza ukwenza lula inqubo yokukhiqiza lapho ucabangela ukusebenzisa imishini. Noma ngabe uyibhizinisi elincane elikhulayo noma umkhiqizi onolwazi ofuna ukusebenza kahle, kubalulekile ukuthi uyazi ngale mishini.

Masiqhubeke.

Ngaphambi kokuthi uqonde ukuthi zinjani umshini wokupakisha amantongomane yakhiwe futhi yasetshenziswa, kubalulekile ukuthi uqale uqonde ukuthi le mishini iyini.

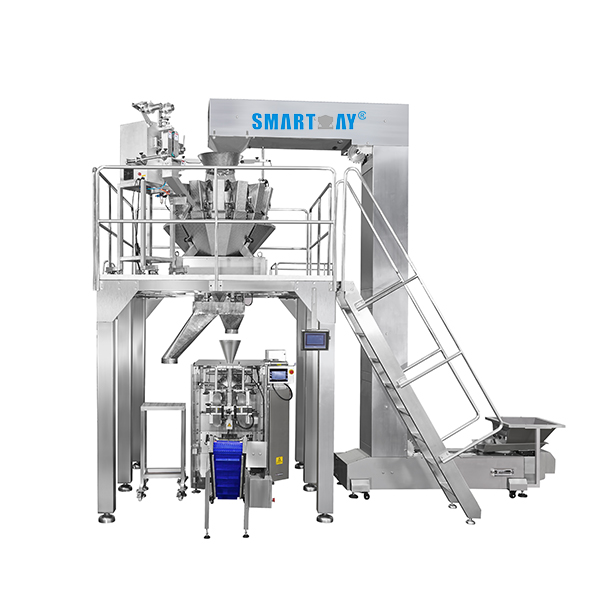

Imishini yokupakisha amantongomane iyimishini eklanyelwe ukugcwalisa ngokushesha nangempumelelo izinhlobo ezahlukene zamantongomane ezitsheni noma ezikhwameni. Afakwe izingxenye eziningana: ama-conveyors, amasistimu wokugcwalisa isisindo, nomshini wokupakisha wokuvala, ukubiza nje ezinye.

Le mishini ifaka izinto ezizenzakalelayo, ihlola njalo isisindo, ikhwalithi, kanye namazinga enhlanzeko. Kungaba ukupakisha ama-alimondi, amakinati, ama-cashews, nanoma yiziphi ezinye izinhlobo zamantongomane; le mishini enemvelo eguquguqukayo ingenza izithombe ezahlukahlukene kanye nenani lokupakisha.

Ezinye zezingxenye ezibalulekile ze umshini wokupakisha amantongomane we-cashew zihlanganisa:

✔1. Isiphakeli se-Conveyor: Ihambisa amantongomane endaweni yokugcina noma yokucubungula iwayise emshinini wokukala, iqinisekisa ukuthi kukhona njalo ukutholakala kwamantongomane ohlelweni lokupakisha.

✔2. Isistimu Yokugcwalisa Isisindo: Lolu hlobo lwesistimu yokukala lubalulekile ekuhlukaniseni; ikala ngokunembile amantongomane okufanele afakwe ephaketheni ngalinye, igcina ukuvumelana kwesisindo, futhi, ngokuvamile, ihambisana nezidingo zokulawula.

✔3. Umshini Wokupakisha: Lena inhliziyo yenqubo, egcwalisa futhi ipakishe amantongomane kungaba ezitsheni noma ezikhwameni. Umshini ungahlanganisa okhiye abafana ne-VFFS (Vertical Form-Fill-Seal), i-HFFS (I-Horizontal Form-Fill-Seal) noma umshini wokupakisha ojikelezayo wesikhwama osuselwe kuhlobo lwesethulo sephakheji futhi uvumelane nokusebenza okufunayo.

✔4. Umshini Webhokisi (Uma uthanda): Umshini we-cartoning usetshenziswa ekufakweni kwenqwaba. Ngokuzenzakalelayo idosa amantongomane emabhokisini ekhadibhodi futhi igoqe bese ivala amabhokisi, abese ethunyelwa ezinqubweni zokupakisha ezilandelayo.

✔5. Umshini Wokunamathisela (Ongakukhetha): Ihlanganisa ingxube yezakhi ezigcwele ngendlela ezinzile futhi ehlelekile kuma-pallets ukuze agcinwe noma athuthelwe.

Lokhu kusiza lezo zingxenye ukuthi zivumelane zodwa, ngaleyo ndlela kuvumelane isistimu ezishintshayo ngesikhathi sokupakishwa kwamantongomane ukuze kwandiswe ukusebenza kahle nokusebenza kahle, kuqhubeke nokuqinisekisa ikhwalithi yemikhiqizo.

Jabulela inala yemishini eklanyelwe ukupakisha izinhlobo ezahlukene zamantongomane, ucabangela ukukhiqiza kwawo kanye nezinga lokuphuma kwawo.

Nazi ezimbalwa zezinhlobo ezivame kakhulu:

· Imishini ezenzakalelayo: Le mishini yenza yonke into kusukela ekugcwaliseni kuya ekuvaleni ngokuphazamiseka okuncane komuntu. Kuyafaneleka noma yikuphi ukukhiqizwa kwevolumu ephezulu futhi kuqinisekisa ikhwalithi ehlala njalo emaphaketheni.

· Imishini ezenzakalelayo: Ngamagama alula, le mishini idinga ukungenelela okuncane okwenziwa ngesandla—ikakhulukazi ukulayisha izikhwama noma iziqukathi nokuqala inqubo yokupakisha. Zinhle kakhulu emisebenzini yokupakisha enesivinini esiphansi noma lapho imikhiqizo inokushintshashintsha njalo.

Yonke imishini ye-VFFS isetshenziselwa ukwakha nokwenza izikhwama ngefilimu yokupakisha futhi, ngemva kwalokho, igcwalise ngamantongomane bese udala uphawu oluqondile. Ngakho-ke, angasetshenziswa ukupakisha amantongomane ngokuphumelelayo ezikhwameni ezinobukhulu obuhlukahlukene; ngakho-ke, baphatha kalula ezinye izinto zokupakisha.

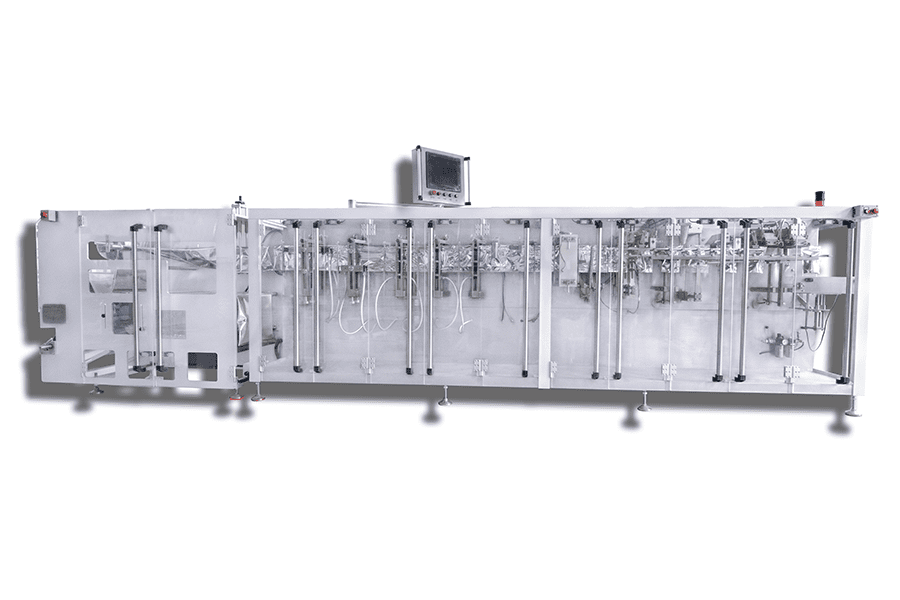

Imishini esetshenziselwa ukuma okuvundlile futhi yenza amantongomane apakishwe ngokuyinhloko esikhwameni esenziwe ngaphambilini noma esikhwameni. Lokhu okunikezwayo kufaka phakathi imishini ye-HFFS, elungele imisebenzi yokufaka izikhwama enesivinini esikhulu futhi ehlotshaniswa nokuthuthukiswa okuphinde kwasetshenziswa amathuluzi.

Basebenza ngokukhethekile ngezikhwama ezenziwe ngaphambilini. Kunezinhlobo ezimbili zemishini, ejikelezayo futhi evundlile, kodwa ukusebenza kuyafana: ukucosha izikhwama ezingenalutho, ukuvula, ukuphrinta, ukugcwalisa, nokuvala amantongomane nokudla okomile kuzikhwama ezikhiqiziwe ngendlela ephumelelayo, ngezinketho zokuvalwa kweziphu noma ama-spouts okunikezwayo. lula kumsebenzisi.Ukukhethwa kohlobo olufanele lomshini wokupakisha kwenziwa ngokusekelwe kumthamo wokukhiphayo, okuthandwa yifomethi yokupakisha, kanye ne-automation.

Nansi indlela umshini owakhiwa ngayo futhi usetshenziselwe ukupakisha amantongomane :

Ngaphambi kokuqala, imishini yokupakisha amantongomane kufanele isethwe kahle ukuze kuqinisekiswe ukuthi isebenza kahle kakhulu futhi kungathenjelwa kuyo.

▶Ukufaka nokusetha:

Ibekwe phezu kwesisekelo esiqinile njengoba kuchazwe emiyalweni yomkhiqizi kanye nemibandela yezinyathelo zokuphepha. Lokhu kuyibeka ngaphansi kokukhwezwa ngokomzimba, ukuvimbela imithwalo enhlanhlathayo phakathi nokugeleza kwezinto.

▶ Ukulinganisa nokulungiswa:

Ngakho-ke, okulinganiselwe yizingxenye ezibalulekile zesistimu yokukala ukuze kuqinisekiswe izilinganiso ezinembile zamantongomane. Lokhu kuqinisekisa ngokukhethekileyo ukuthi izingxenye ziyafana futhi zilandela izilawuli ezivunyelwe zokulawula.

▶ Ukulungiselela Material:

Imiqulu yefilimu esetshenziswa nemishini ye-VFFS noma izikhwama ezakhiwe ngaphambili ezisetshenziswa nemishini ye-HFFS ziyalungiswa futhi zilayishwe emshinini, yingakho zivumela futhi zinikeze ukupakishwa okungenamthungo.

Ekusebenzeni, ukulandelana kwezinyathelo ezifanele ngemishini yokupakisha amantongomane kwenza amantongomane ahlanganiswe ngempumelelo:

▶ Ukondla kanye Nokudlulisa:

Isiteshi se-lugs siphakela amantongomane emshinini. Basiza ukondla amantongomane ngokuqhubekayo, bagcine ukuhlinzwa kungashintshi ukusuka phezulu kuye phansi.

▶Isisindo kanye nokuhlukaniswa:

Ikala inani lamantongomane adingekayo ukuze libe kuwo wonke amaphakheji. Isizukulwane esilandelayo sinesofthiwe kuzo ukuze zivumelane nokuminyana kwesisindo samantongomane, ngaleyo ndlela siqinisekise ukuthi iphakethe ngalinye eliqediwe lizoba nesisindo esithile.

▶Ukupakisha:

Okwenziwa yile mishini ukugcwalisa amantongomane esikhwameni noma esikhwameni, kuye ngezinhlobonhlobo zemishini etholakalayo, njenge-VFFS ne-HFFS. Le mishini ingakha, igcwalise, futhi ivale kahle amaphakheji ngezinqubo ezinembile.

Eminye imishini ephatha izikhwama ezenziwe ngaphambilini ingumshini wokupakisha ojikelezayo futhi ovundlile, uyakhetha, ugcwalise futhi uvale ngokuzenzakalelayo izinhlobo eziningi zezikhwama ezenziwe kusengaphambili.

Izinyathelo zokulawula ikhwalithi zifakwa enqubweni yokupakisha ukuze kuqinisekiswe ikhwalithi nokuphepha komkhiqizo :

▶ Isitholi sensimbi:

Ngokukhiqiza amandla kazibuthe kanye nokuthola noma yikuphi ukuphazamiseka okubangelwa izinto zensimbi, kuvumela ukususwa ngokushesha kwezinto ezingcolile, ukuvikela ukuphepha kwabathengi kanye nobuqotho bomkhiqizo. Iskena imikhiqizo ngokucophelela ukuze ithole ukungcola kwensimbi, iqinisekisa ukuphepha okuphezulu nokuhambisana nezindinganiso eziqinile zekhwalithi. Lokhu, futhi, kunciphisa izehlakalo zokukhunjulwa komkhiqizo kodwa kusaqinisekisa ukuvikela amaklayenti ngokuthula kwengqondo nokuvikela ukuzethemba kwamakhasimende.

▶Hlola Isisindo:

I-checkweigher iwuhlelo oluzenzakalelayo olubalulekile olusetshenziswa emigqeni yokukhiqiza ukuze kuqinisekiswe isisindo somkhiqizo esinembile. Ikala ngokunembile imikhiqizo njengoba ihamba ngebhande lokuthutha, iqhathanisa isisindo sangempela namazinga asethiwe. Noma yimiphi imikhiqizo ewela ngaphandle kwebanga lesisindo esidingekayo inqatshwa ngokuzenzakalelayo. Le nqubo iqinisekisa ukungaguquguquki, inciphisa ukumosha, futhi iphakamisa ukwaneliseka kwamakhasimende ngokuletha imikhiqizo ehlangabezana nezimfuneko eziqondile.

Lezi zingapakisha amantongomane ngokuhamba kwesikhathi futhi, ngemva kokuhlinzwa, zenze imisebenzi ebalulekile ngesikhathi ukuze zithole imikhiqizo efanele inqubo yokusabalalisa.

▶ Ukulebula nokubhala ikhodi:

Ngokuyisisekelo, imininingwane yomkhiqizo, izinombolo zeqoqo, izinsuku zokuphelelwa yisikhathi, nolwazi lwebhakhodi eminye yemininingwane enamathiselwe kulebula esemaphaketheni. Lolu hlobo lwamalebula luvumela ukulandeleka nokugcinwa kwesitoko.

▶ I-Cartoning (uma ikhona):

Imishini ye-automating cartoning iyasonga futhi ivale amabhokisi amakhadibhodi, abese elungele ukupakishwa ngobuningi noma ukuhlolwa ezingeni lokudayisa; kamuva agcwaliswa ngamantongomane asepakishwe ngaphambilini. Isiza ekwenzeni kahle izinqubo zokupakisha yonke imikhiqizo kanye nokuthunyelwa okunembile.

▶ I-Palletizing (uma ikhona):

Imishini yokufaka i-palletizing imishini esetshenziswa ukuhlela kahle imikhiqizo epakishiwe kuma-pallets ngendlela yokuthi azozinza. Lokhu kuzosiza ukwandisa isitoreji okungenzeka sithuthwe kahle noma sisatshalaliswe ezitolo noma kumakhasimende.

Ngakho-ke, lokhu kwenza imishini yokupakisha isikhwama se-cashew ibambe iqhaza elibalulekile ekupakisheni kahle amantongomane ahlukene ezikhwameni noma kwezinye iziqukathi. Basebenzisa izingxenye eziningana, ezihlanganisa abathumeli, izinhlelo zokugcwalisa isisindo, namapaki, ukuze bathole ukufana ngokwekhwalithi yamaphakheji.

Uyabona, noma ngabe ufuna ukuyofuna umshini ozenzakalelayo noma we-semiautomatic, noma unezinzuzo zawo ezithile, kwesinye isikhathi eziphathelene nalokho okukhiqizayo.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe