Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Have you ever wondered how packaging machines for nuts help you in simple packing, as well as quality maintenance? This is because the process from fresh to complete packing can be pretty tricky sometimes.

This article discusses packaging machines for nuts while providing some practical tips to help simplify the production process when considering using the machines. Whether you are a small business growing or an experienced manufacturer looking for efficiency, it is essential that you are aware of these machines.

Let's get it going.

Before getting straight to how are the nuts packaging machine composed and used, it's essential to first understand what these machines are.

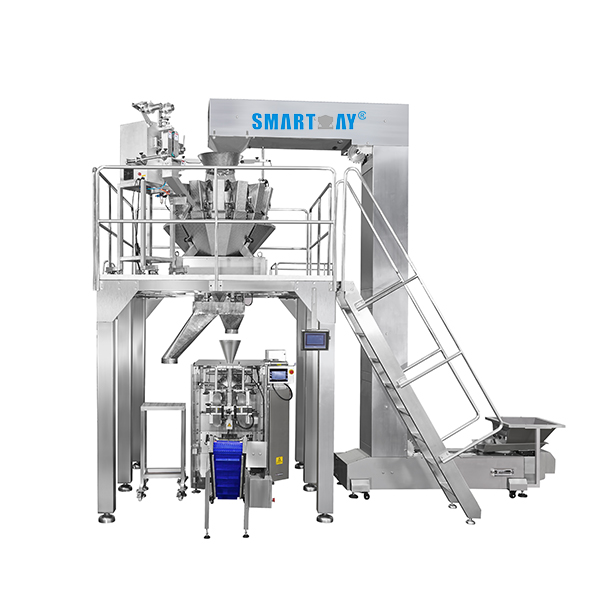

Nuts packing machines are specifically designed machinery for quickly and effectively filling different types of nuts into containers or bags. They are equipped with several parts: conveyors, weighing filling systems, and sealing packing machine, just to name some.

These machines cradle automatic packaging, consistently checking weight, quality, and hygiene standards. Be it packing almonds, peanuts, cashews, or any other variety of nuts; these versatile natured machines can undertake different images and volumes of packaging.

Some of the key parts of the cashew nut packing machine include:

✔1. Feed Conveyor: It moves nuts from storage or processing areas into a weighing machine, ensuring that there is always a supply of nuts to the packaging process.

✔2. Weighing Filling System: This kind of weighing system is essential in portioning; it accurately weighs the nuts to be inserted in each package, maintains consistency of weight, and is, in general, compliant with regulatory requirements.

✔3. Packaging Machine: This is the heart of the process, which fills and packages the nuts in either containers or bags. The machine can incorporate keys such as VFFS (Vertical Form-Fill-Seal), HFFS (Horizontal Form-Fill-Seal) or rotary pouch packing machine based on the type of package presentation and accord the performance desired.

✔4. Cartoning Machine (Optional): The cartoning machine is used in bulk packaging. It automatically doses the nuts into the cardboard boxes and folds and closes the boxes, which are then sent for subsequent packaging processes.

✔5. Palletizing Machine(Optional): It palletizes the packed nutrient mix in a stable and organized manner onto pallets for storage or transportation.

This helps those components synchronize with each other, thereby harmonizing the automation system during the packaging of nuts to increase effectiveness and efficiency, further ensuring the quality of the products.

Enjoy the abundance of machines designed to package different kinds of nuts, taking into account their productivity and output level.

Here are a few of the more common types:

· Automatic Machines: These machines do everything from filling to sealing with minimum human interference. It is worth any high-volume production and guarantees constant quality in packaging.

· Semi-automatic Machines: In simple terms, these machines require minimal manual intervention—primarily loading the bags or containers and starting the packaging process. They are excellent for low-speed packaging operations or where products have relatively frequent changeovers.

All the VFFS machines are used to form and make bags from packaging film and, after that, fill them with nuts and create a vertical seal. Therefore, they can be used to package nuts efficiently in bags of different sizes; hence, they handle readily most other packaging materials.

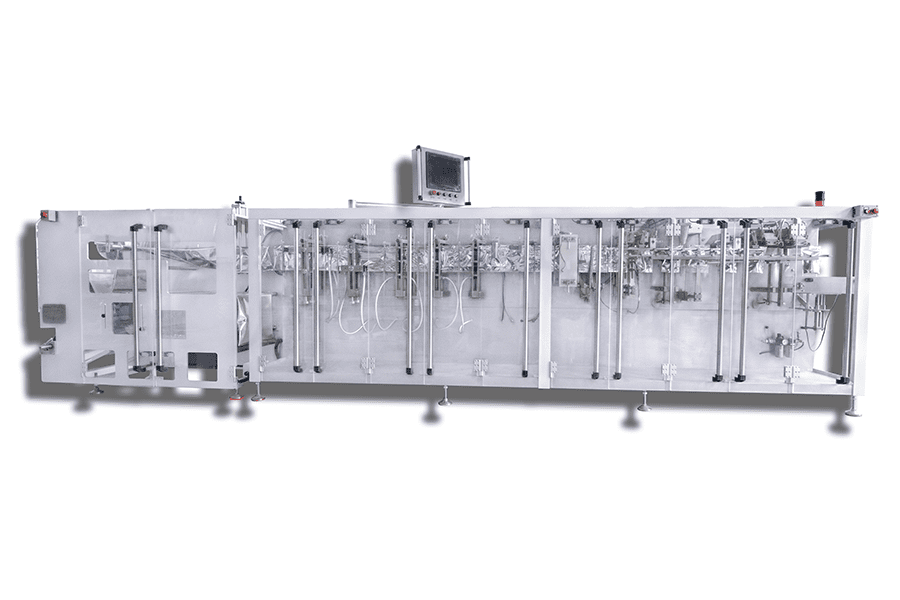

The machines used for horizontal form and make ideally package nuts primarily into a pre-made bag or pouch. These offers include HFFS machines, which are suitable for high-speed bagging operations and are associated with re-tooled advancements.

They specialize in dealing with pre-made pouches. There are two types of machines, rotary and horizontal, but the operations are the same: picking up empty pouches, opening, printing, filling, and sealing nuts and dry foods into manufactured pouches relatively effectively, with options for zipper closures or spouts to offer convenience for the user.The selection of the appropriate type of packaging machine is conducted based on the volume of output, preference of packaging format, and automation.

Here's how the machine is built and used for packing nuts :

Before starting, nuts packaging machines must be correctly set up to make sure they work excellently and can be relied upon.

▶Installation and Setup:

It is mounted on a rigid foundation as described in the manufacturer's instructions and stipulations of safety measures. These subjected it to a physical mounting, preventing deviant loads during material flow.

▶ Calibration and Adjustment:

Calibrated, therefore, are the weighing system's critical components to ensure accurate measurements of nuts. This is exceptionally ensure that portions are pretty consistent and follow the allowed regulatory controls.

▶ Material Preparation:

The rolls of film used with VFFS machines or pre-formed pouches used with HFFS machines are prepared and loaded into the machine, hence allowing and offering seamless packaging.

In operation, the sequence of the correct steps by nuts packing machines makes nuts be effectively packaged:

▶ Feeding and Conveyance:

The station of lugs feeds the nuts into the machine. They help feed nuts continuously, keeping the operation constant from top to bottom.

▶Weighing and Portioning:

It measures the amount of nuts needed to be in all packages. The next generation has the software in them so that they adapt to the density of the nut mass, thus ensuring that each finished package will have a specific weight.

▶Packaging:

What these machines do is fill the nuts in either a bag or a pouch, depending on the variety of the machines available, such as VFFS and HFFS. These machines can form, fill, and seal packages efficiently by precise mechanisms.

Another machines which handle premade pouches are rotary and horizontal pouch packaging machine, they pick, fill and seal most kinds of premade pouches automatically.

Quality control measures are incorporated into the packaging process to ensure the quality and safety of the product :

▶ Metal detector:

By generating a magnetic field and detecting any disruptions caused by metal objects, it allows for the immediate removal of contaminated items, protecting consumer safety and product integrity. It meticulously scans products to detect metal contaminants, ensuring the highest safety and compliance with stringent quality standards. This, in turn, minimizes the incidence of product recalls but still ensures protecting clients with peace of mind and protecting customer confidence.

A checkweigher is an indispensable automated system used in production lines to guarantee precise product weight. It accurately weighs products as they move along a conveyor belt, comparing the actual weight to preset standards. Any products that fall outside the required weight range are automatically rejected. This process ensures consistency, minimizes waste, and upholds customer satisfaction by delivering products that meet exact specifications.

These can later pack the nuts and, post-operation, perform the essential tasks in time to get the products right for the process of distribution.

▶ Labeling and Coding:

Basically, product details, batch numbers, expiry dates, and barcode information are some of the details attached to the label on the packages. This type of labelling allows for traceability and stock-keeping.

▶ Cartoning (if applicable):

Automated cartoning machines fold and seal the cardboard boxes, which are then ready for bulk packaging or inspection at the retail level; they are later filled with pre-packaged nuts. It aids in smoothing the processes of packaging all the products and in accurate shipment.

▶ Palletizing (if applicable):

Palletizing machines are devices applied to properly organize packaged products onto pallets in such a way that they will be stable. This will help maximize storage possible to be transported efficiently or distributed to retail stores or customers.

Therefore, this makes cashew pouch packing machines assume a vital role in efficiently packing different nuts into bags or other containers. They apply several components, which include conveyors, weighing filling systems, and packers, to achieve uniformity in terms of the quality of packages.

You see, whether you want to go for an automatic or semiautomatic machine, either has its specific advantages, sometimes relating to what you're producing.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved