Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

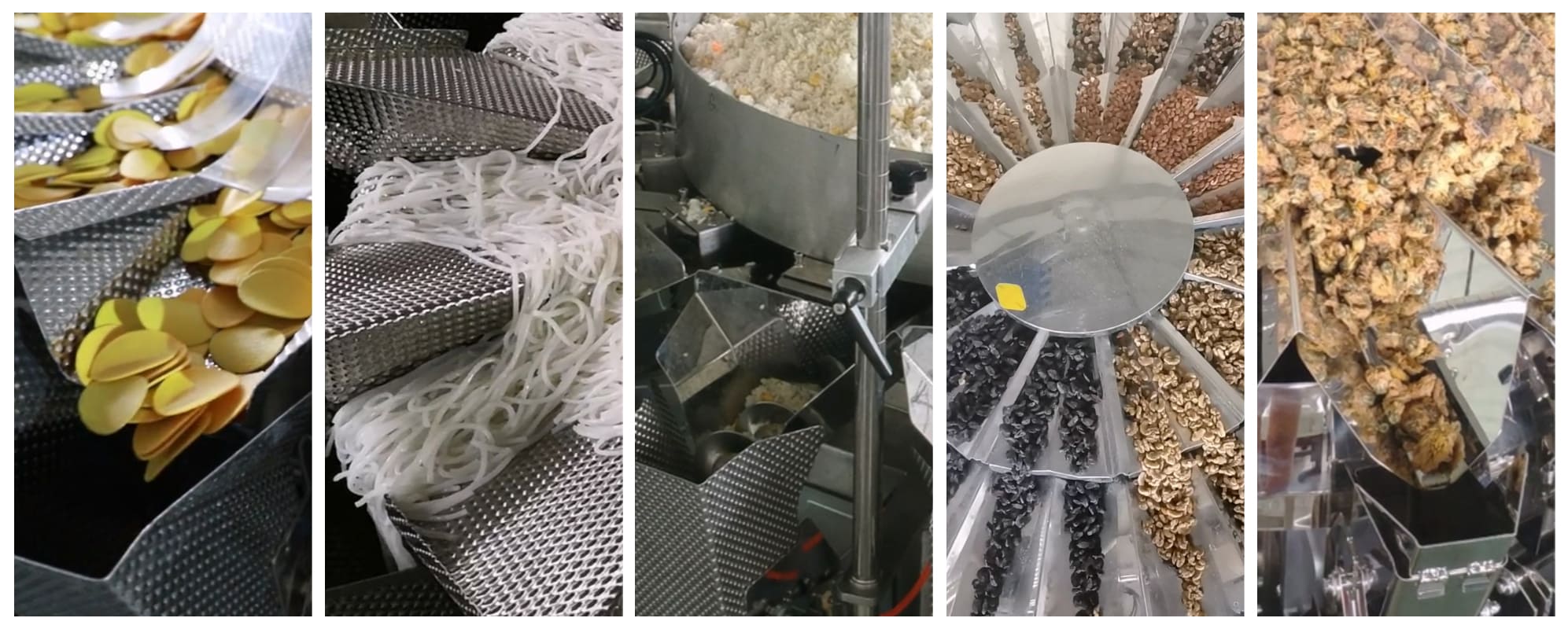

Multihead Combination Weighers have changed the game in industrial weighing. These machines can perform up to 120 weighments per minute and measure products to fractions of a gram. Their precision has set new standards in food manufacturing and packaging operations.

These weighing systems have become indispensable since their creation in the 1970s. They handle various products, from fresh meats and produce to confections and pet food. The systems feature 10 to 32 heads that work together to mix up to eight different components. Each head maintains exact measurements while reducing product waste.

This article shows how a multi head combination weigher can improve business operations and deliver reliable results. Business owners who manage food processing facilities or packaging operations need to understand these advanced weighing solutions. This knowledge helps them stay competitive in today's ever-changing manufacturing environment.

A multihead combination weigher is a sophisticated weighing system that uses multiple weighing units to measure products precisely. Ishida developed this technology in 1972, and these weighers now make up about 50% of the global market. The system breaks down bulk products into smaller, precisely measured portions through specialized components that work together seamlessly.

Products enter through an infeed funnel at the top. A distribution cone then spreads the materials evenly across multiple feed pans. Each weigh hopper has precision load cells that work as the system's "beating heart." These load cells measure product weights continuously and come with built-in calibration weights that adjust automatically to keep accuracy during production.

The computer system looks at combinations from individual weigh hoppers and finds the best mix to match the target weight. Standard models come with 10 to 24 heads, and more heads give extra combination options for better accuracy.

Multi head combination weigher come in different configurations to meet the needs of various industries. Each type has unique features that help it perform at its best.

Snack weighers are designed to handle a variety of products, from lightweight chips to dense nuts and candies. They feature gentle handling mechanisms to prevent breakage and maintain product integrity. Key features include:

● Adjustable vibration settings for delicate products

● Anti-static surfaces to prevent lightweight snacks from sticking

● Easy-to-clean designs to handle oily or powdery residues

● High-speed weighing capabilities to meet production demands

These weighers have embossed stainless steel surfaces and automatic feed control systems that help maintain product quality. They can handle 60 weighments per minute for heavier, free-flowing products. These systems are perfect for fruits and vegetables and include:

● Self-draining sloped surfaces

● Springless hoppers

● Higher waterproof grade construction that prevents bacterial growth

● Special surfaces that reduce product damage

Modern weighing systems can handle fresh, frozen, and prepared meat products. Instead of standard vibration methods, they use belts or screw feeders that work well with sticky products like fresh meat and poultry. The machines meet USDA Dairy Standards and maintain high hygiene levels.

Weighers made for detergents come with U-shaped linear feed pans that control free-flowing granular products. They feature sealed dust enclosures and extra bucket sealing to stop leaks. These machines are exceptionally durable and work well even in harsh conditions.

Hardware component weighers need special setups to handle small parts. They provide precise control when weighing nuts, bolts, and fasteners of all sizes. These weighers are built tough but handle products gently to protect both the machine and components.

Choosing the right multihead combination weigher depends on several key factors that need careful evaluation.

Understanding product properties is the foundation of making the right choice. Products that stick need specialized rotary screw feeders, while fragile items work better with linear weighers that handle them gently. Products with unique features need specific equipment - embossed surfaces work well for fresh produce and sealed enclosures suit powders best.

Production speeds should line up with what you need to make. Standard applications on modern weighers can handle up to 210 weighments per minute, though speeds change based on what you're weighing. The weighing range and bucket size affect how much you can process, and without a doubt, this shapes your total output potential.

Smart investment choices look at returns over time. A high-performance weigher cuts product giveaway by 15% and boosts efficiency by 30% through automation. Your choice of features affects the cost:

● Advanced software integration capabilities

● Customizable feeding systems

● Sanitary design requirements

● Maintenance accessibility options

Making sure new equipment works with current production lines is vital for smooth operations. The weigher should line up properly with packaging equipment like bagmakers and inspection systems. Modern systems come with pre-programmable settings, but you still need to check:

● Discharge point configurations

● Control system compatibility

● Data collection capabilities

● Maintenance requirements

The selection process should balance what you need now with room to grow later. The upfront costs might look high, but better accuracy and less waste usually make the investment worth it.

A detailed product matrix that outlines target weights and specific product characteristics starts the successful evaluation of multi head combination weighers. Manufacturers can determine the best equipment configurations through this integrated approach.

Product sample testing is vital before making a purchase decision. These tests show if your product works well with specific scales. We tested two key areas: product contact surfaces and linear feed pan options since manufacturers provide different configurations for these components.

Here are the vital factors to look at when you compare models:

● Accuracy rates and consistency metrics

● System compatibility with existing protocols

● Production capacity versus actual needs

● Total ownership costs, including maintenance

● Warranty coverage and support services

Bucket sizing specifications are vital to the process, and different manufacturers use their own measurement standards. You should ask multiple suppliers about these specifications to get accurate comparisons and avoid mismatched expectations.

The setup process needs careful planning since operators often use trial-and-error methods that might not yield the best results. Working with manufacturers who offer excellent support services, including employee training and mechanical debugging, will benefit you.

The evaluation should go beyond the purchase price. You need to think over long-term service contracts and spare parts management solutions. Some manufacturers give two-year warranty coverage, while others have different terms based on machine quality and pricing structures.

The Weigher's software should handle data collection and analysis well to track performance. Optimizing hopper weights and keeping precise target measurements greatly affects operational efficiency. This technical feature directly affects package weight consistency and material costs.

Smart Weigh Pack stands out as a trusted leader in the weighing and packaging industry, offering innovative solutions tailored to many industries. It was established in 2012. Smart Weigh has over a decade of expertise and combines cutting-edge technology with a deep understanding of market needs to deliver high-speed, accurate, and reliable machines.

Our comprehensive product range includes multihead weighers, vertical packaging systems, and complete turnkey solutions for food and non-food industries. Our skilled R&D team and 20+ global support engineers ensure seamless integration into your production line, catering to your unique business needs.

Smart Weigh's commitment to quality and cost-efficiency has earned us partnerships in over 50 countries, proving our ability to meet global standards. Choose Smart Weigh Pack for innovative designs, unmatched reliability, and 24/7 support that empower your business to increase productivity while reducing operational costs.

Multihead combination weighers play a crucial role in modern manufacturing, offering up to 600 precise weighments per minute. Small improvements in accuracy can save businesses thousands of dollars weekly. Smart Weigh Pack, a leader in weighing solutions, has helped over 1,000 clients in 50 countries achieve these results.

Their weighers are suitable for various industries, including food, pharmaceuticals, and hardware. These machines improve efficiency, reduce waste, and ensure consistent product quality, making them a smart investment for any business. If you’re ready to enhance your production efficiency, explore Smart Weigh Pack’s complete range of solutions at Smart Weigh. With 24/7 global support and tailored solutions, they help businesses maximize their returns through better accuracy and lower costs.

Modern manufacturing thrives on precision, speed, and reliability. Smart Weigh Pack’s proven expertise and innovative solutions make them the ideal partner for upgrading your weighing and packaging processes.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved