Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Adding a new food packaging machine line is a big decision requiring careful consideration. The right packaging machinery can increase efficiency, reduce labor costs and improve product safety and shelf life. But with so many factors to consider, making the right choice can be tough. From speed and cost to environmental impact and flexibility, there are many things to evaluate before committing to a new machine. This article will look at the key things to consider when adding a new food packing machine line so your investment meets your business needs.

Modern food packing machinery plays a major role in the food industry. Its contribution is in how it securely packs foods, maintaining them fresh and durable. The machinery keeps foods from contamination and dust, bacteria, and moisture. It also boosts efficiency, allowing foods to be packaged more rapidly and reducing wastage.

With advanced machinery, packages today can hold a range of foods, from grains and snacks to liquid foods, and maintain them in optimal shape. Proper identification also happens with their use, with consumers receiving useful information such as what's inside when they expire and what's in them.

Another key benefit is extended shelf life which reduces food spoilage and helps businesses save money. Automated packaging machines reduce labor costs and increase production speed. Modern food packaging equipments are essential for food safety, efficiency and meeting consumer demands in today’s fast paced world.

When adding a new pack machine line, there are a variety of factors to consider when making the optimal possible investment. These are:

One of the earliest factors to consider is your company's output requirements and how the new pack machinery line can accommodate those needs. Research your current and future output levels and choose the machinery best for your company. A small food company with low output may not require industrial-strength machinery, and large-volume food companies need high-speed pack systems for their output levels.

The machine’s rate of working has to be commensurate with your plans for your firm. There are some of them that can pack hundreds, even thousands, of merchandise in a single hour, but if your requirements don't demand such volume, purchasing a very fast system may not be worth the expenditure. Conversely, purchasing a slow machine when your company needs volume can be wasteful and can create bottlenecks in your plant.

Food safety is of paramount significance in the industry, and the packaging machinery must comply with regional and international food safety regulations. Depending on your location and the foods being packaged, the machinery must also comply with industry regulations, including CE.

Some things to look for:

● Stainless steel fabrication for prevention of contamination

● Easy-to-clean components for maintaining hygiene

● Compliance with Allergen Management Protocols

Failure to comply with regulations on food safety can lead to legal action, sanctions, and damage to your brand's reputation. Therefore, your top priority must be selecting machinery for your packages that guarantee food safety.

Automation plays a big role in modern food packaging lines. Automated systems can increase efficiency, reduce labor costs and improve consistency in packaging. Depending on your needs you may choose fully automated, semi automated or manual packaging lines.

Consider whether the machinery interacts with other available technology such as

● Monitoring systems for real-time data tracking

● Programmable logic controllers (PLCs) for easy use

● Automated quality check systems for identifying faulty packages

Fully automated systems reduce human error and can work around the clock, but they come at a higher upfront cost. On the other hand, semi-automated systems provide flexibility while still requiring some human intervention.

The type of material with which you pack must be commensurate with your machine's capacity. The material for packaging foods also has a wide variety and includes plastic, glass, metal, and environment-friendly. Your machine should be able to use the material best for yourproduct and also be compliant with sustainability.

Some considerations include:

● Heat-sealing compatibility of flexible packages

● Rigid packaging for glass jars and metal can

● Eco-friendly material solutions for sustainability-driven companies

Investing in a machine with versatility for use with different packaging materials can be a source of future flexibility and savings.

The cost of a new range of food-packaging machinery can be substantial, and hence, measuring the rate of return on investment becomes very critical. Besides the buying price, other factors such as:

● Installation costs

● Training expenses for operators

● Maintenance and Repair Expenditure

● Energy consumption

A cost-benefit analysis can determine whether the expenditure is worthwhile. Expensive, quality machinery offers greater performance, longevity, and lower overall usage costs.

Not all packaged foods are equal. If your firm offers a range of different foods, choosing a machine with customization can be beneficial. Some of them can be rapidly changed for different packaging, forms, and sizes.

Features that offer flexibility:

● Adjustable filling heads for liquid and solid foods

● Multi-functionality to accommodate changing between pack formats (e.g., cartons, trays, pouches)

● Modular design for easy upgradation and customization

A flexible machine keeps your company from being locked into a single style of packaging, allowing your firm to be able to accommodate changing markets and customer trends.

Before investing in a food-packaging machinery line, check your plant's available space. Large industrial machinery must be allocated plenty of space on the factory floor, and without proper planning, workflow inefficiencies can be created.

Key considerations are:

● The machine’s footprint and where it will be located in your working space

● Ease of access for operators and maintenance personnel

● Workflow integration for smooth movement of packaged goods and raw material

Some manufacturers also provide layout planning assistance for optimal placement of new machinery on existing lines of production.

With increasing awareness of sustainability, energy-efficient packaging machines are gaining popularity. Machines that consume less energy reduce operational costs and minimize environmental impact.

When selecting a machine, find

● Energy-efficient motors and devices

● Reduced packaging waste through precise material handling

● Compliance with Sustainability certifications including Energy Star

Environmentally friendly machinery for packages reinforces corporate social responsibility (CSR) practices and also appeals to consumers with ecological values.

Purchasing packaging machinery from a reputable vendor means that you will be able to achieve a stable product and quality customer support. Research the vendors and read customer reviews, testimonies, and case studies.

After sales support services to consider:

● Warranty for parts and labor

● Spare parts availability

● Technical support and troubleshooting assistance

A vendor with good customer service can minimize downtime and ensure smooth operation of your packaging line.

Even the most advanced packaging machines require skilled operators. Ensure employees are properly trained to reduce operational errors and improve efficiency.

Some training options:

● Onsite training by the manufacturer

● Online video tutorials and manuals

● Third party certification courses for machine operators

Investing in employee training ensures the packaging line runs smoothly and safely.

New food packaging machine line offers:

● Increased Production Efficiency: Automated machines speed up and standardize, reducing manual labor.

● Less Material Waste: Precise portioning and packaging minimize product loss and sustainability.

● Consistent Product Quality and Portion Control: Advanced packaging systems ensure uniform product presentation and weight accuracy.

● Better Safety and Hygiene: Modern machines designed for strict hygiene standards, reduce contamination risk.

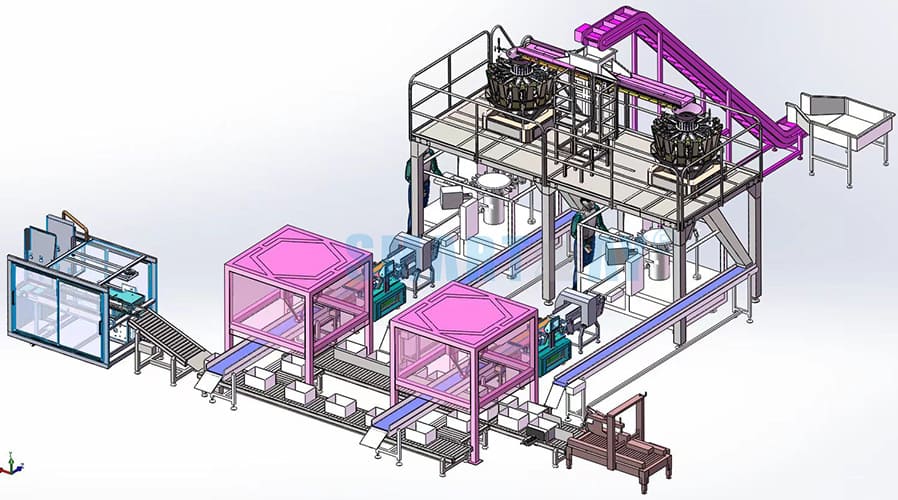

Smart Weigh Pack has a proven history of weighing and packaging solutions with top quality, innovative, and fully automatic systems for the food and non-food industries, such as pouch packaging machine, automation packaging system etc,. With 1,000 systems installed in 50+ countries, we present value-driven and effective solutions for your needs.

Our technology ensures precision, speed, and reliability to help you improve productivity and reduce waste. We offer customization, ODM support, and 24/7 global support. With a strong R&D team and 20+ engineers for overseas service, we provide excellent technical and after-sales support.

Smart Weigh Pack values long term partnership, working closely with customers to develop solutions. From a fully ready-to-run packaging lineup to a customized machine, we are committed to developing top-performing systems for your organization.

Investing in a new food packaging machine line is a big investment that requires careful planning. You can make an informed decision by considering production needs, food safety regulations, automation level, packaging material compatibility, cost, and ROI. Also, ensure machine flexibility, energy efficiency, vendor reliability, and proper employee training to maximize the benefits of your investment.

The right food packaging equipment can improve efficiency, reduce cost, food safety and business growth. Take your time to evaluate all before you purchase to ensure your packaging line aligns with your business goal and customer expectations.

For more information on choosing the right machinery, visit Smart Weigh Pack and explore our range of food packaging solutions for your business.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved