Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Frozen food packaging machines have evolved as valuable additions to the food industry, ensuring that the frozen food inside remains hydrated and fresh for a longer time.

These machines come in an extensive range of sizes and designs to cater to different edible items, from seafood to vegetables and fruits. If you are willing to get one, it is mandatory to first understand which type will suit you the best.

So, keep reading, and in this guide, we will delve into all the essential features you must know about a food packaging machine, including its types, key features, benefits, and factors to consider.

Frozen food packing machines come in multiple types, including the following:

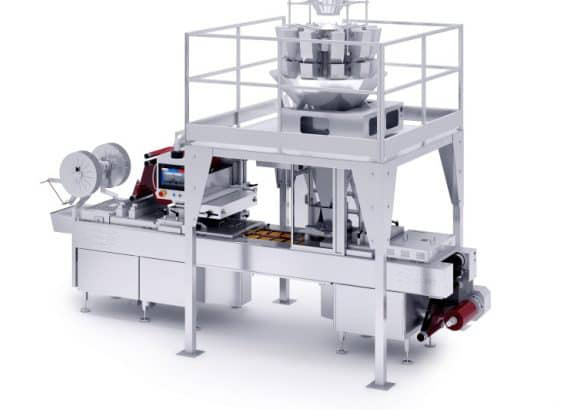

The premade pouch packaging machine is commonly used for seafood with stand-up pouches and bags. It automatically fills the premade pouches with a specific quantity of product and seals.

These frozen food packaging equipments also have multi-head weighers so that all the pouches can be filled with the same quantity and quality of product. It guarantees a perfect pattern with high-quality standards.

At the same time, the sealing system maintains consistent cooling time and pressure to attain seal integrity.

Thermoforming is another popular type of food packaging machine that packs frozen food items into rigid trays.

They heat the sheet of a plastic bag, mold it into a tray shape using vacuum or pressure before packaging. Then the frozen food is placed on the tray, heat sealed with a thinner sheet of plastic on the top.

It is suitable for businesses of all sizes due to its low tooling cost and high-performance mechanism.

Tray sealers provide pretty much the same outcome as the Thermoforming machine. However, they package the food into premade trays instead of crafting the new ones.

The process involves placing the frozen food into the tray and sealing it with a thin yet stretc hable plastic film. Thus ensuring airtight packaging that is ideal for ready-to-eat frozen meals.

These can be operated manually or through a semi-automatic machine, which makes them a perfect option for low-volume production.

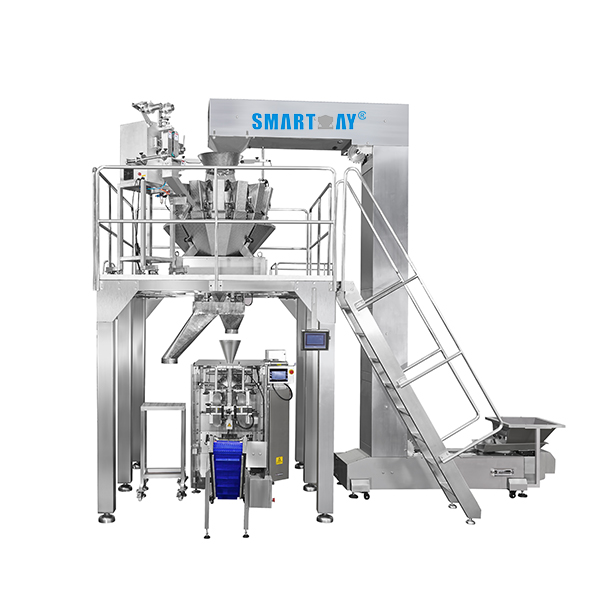

Vertical Form Fill Seal (VFFS) Machine can package multiple types of frozen food items at once. The same is why these are the most commonly used types of food packaging machines- especially in large-scale organizations.

The vertical baggers use a roll of polyethylene or laminated material to form pillow pouches. These pouches are then filled with the frozen food, and sealed from all sides.

These machines are highly automated to facilitate high-volume production within a lesser possible time span.

To ensure getting a well-suited food packaging machine for your business, ensure putting the following factors under consideration:

Different frozen foods require specific packaging needs. For instance, vacuum-sealed options work best for meats, while tray-sealed packaging is ideal for prepared meals.

The machine’s capacity should align with the production demands. High-volume operations need machines that can handle continuous use without compromising quality.

The size of the packaging machine should fit within your facility without disrupting other operations.

If your business infrastructure has a limited space, go with compact designs. However, if you have plenty of space and facilitate large-volume production, choose the bulkier option.

It's crucial to evaluate whether the machine can operate effectively within the existing production environment.

Ensure these machines are engineered to function optimally within specific temperature and humidity ranges. Proper temperature control not only ensures the machinery runs smoothly and efficiently but also preserves the quality and integrity of the packaged products.

Make sure to consider the operational expenses and potential long-term savings to prevent potential losses.

Choose a machine that offers the best value for your investment. You can determine the potential cost by the volume of material you have in the inventory to pack.

Ensure the machine is compatible with the specific materials required for frozen food preservation. This includes plastic films, trays, or pouches.

Select a machine with straightforward maintenance requirements. Look for sellers that are well-reputed for their customer service.

You can judge the customer satisfaction rate by reading customer reviews on the potential seller’s website as well as on their social media pages.

The ability to package large quantities quickly is essential for high-demand operations. Speed without sacrificing quality is a key factor.

Precision in weighing, sealing, and filling minimizes waste and ensures consistency. This is crucial for maintaining brand reputation.

Integrated systems for weighing and filling enhance efficiency. These features ensure that food is accurately portioned in every package.

This feature guarantees airtight packaging with a professional finish. It also reduces the need for manual intervention.

Intuitive control panels simplify operations, reducing the time needed for operator training. Easy-to-use systems boost overall productivity.

Proper packaging preserves freshness, enabling frozen food to remain consumable for extended periods. This is particularly valuable for export markets.

Sealing methods prevent air exposure, reducing the risk of freezer burn. This helps maintain the original quality of the food.

Efficient packaging ensures more food reaches consumers in perfect condition. This minimizes loss due to spoilage or contamination.

Packaging acts as a barrier, safeguarding food from bacteria, dust, and other contaminants. This ensures consumer safety.

Compact designs save storage and transportation space. This reduces logistical costs while improving efficiency.

In the nutshell Frozen food packaging machines are a vital component of the modern food industry. They cater to various frozen food types, from meat to veg items, providing utmost protection and extending shelf life.

At the same time, the high-speed performance, precision, and user-friendly controls make these machines indispensable for frozen food packaging. Some of the popular options include premade pouch packaging machines, thermoforming machines, tray sealers, and VFFS machines. Each type has its unique benefits.

However, one should always focus on performance, precision, and ease of maintenance when selecting a machine. The right choice enhances productivity and minimizes operational challenges.

From preventing freezer burn to reducing food waste, these machines revolutionize frozen food storage and distribution.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved