Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

In today's competitive market, efficiency and precision are crucial for any manufacturing or packaging operation. Automation packaging system offer a seamless solution to streamline processes, reduce labor costs, and enhance product quality. Smart Weigh, a leader in the packaging machinery industry, offers innovative solutions designed to meet the diverse needs of various industries. In this guide, we will explore the different types of automation packaging systems, their components, and the benefits they bring to your production line.

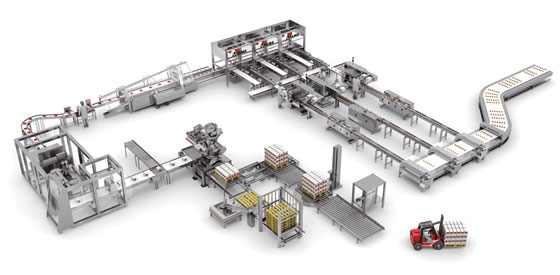

Automated packaging equipment integrate advanced technology with traditional packaging processes to deliver high-speed, accurate, and consistent results. These systems can handle everything from product filling and sealing to labeling and palletizing, making them indispensable for businesses looking to optimize their packaging operations.

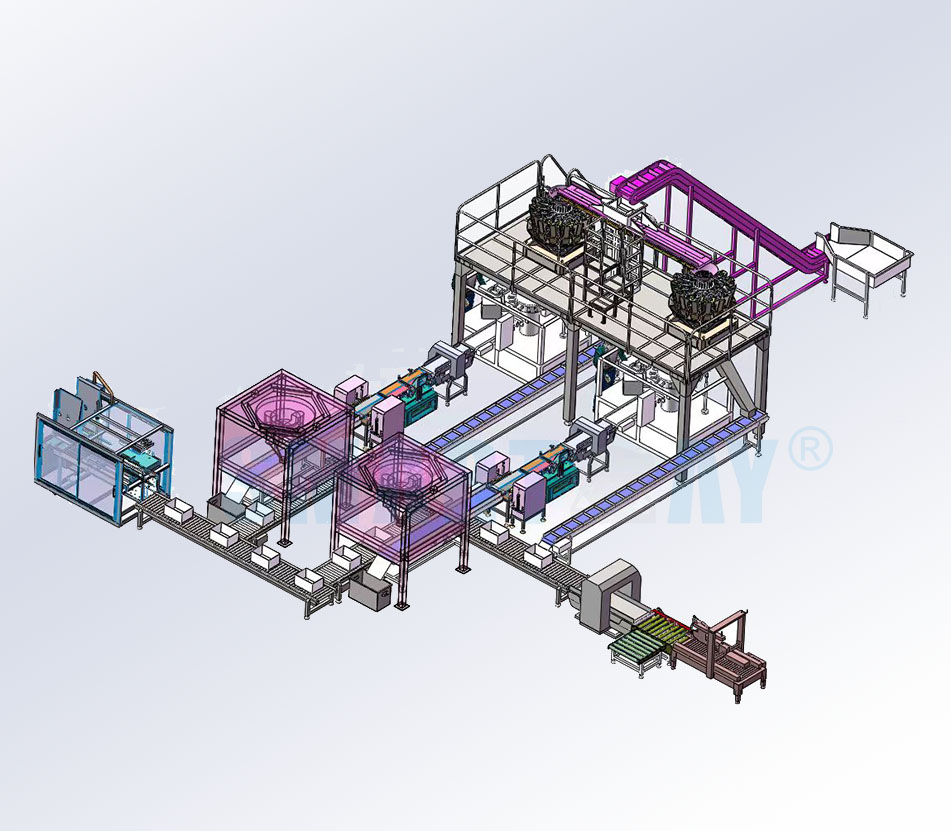

Smart Weigh provides a comprehensive range of automation packaging machines, each designed to address specific stages of the packaging process, ensuring that products are efficiently and effectively prepared for market.

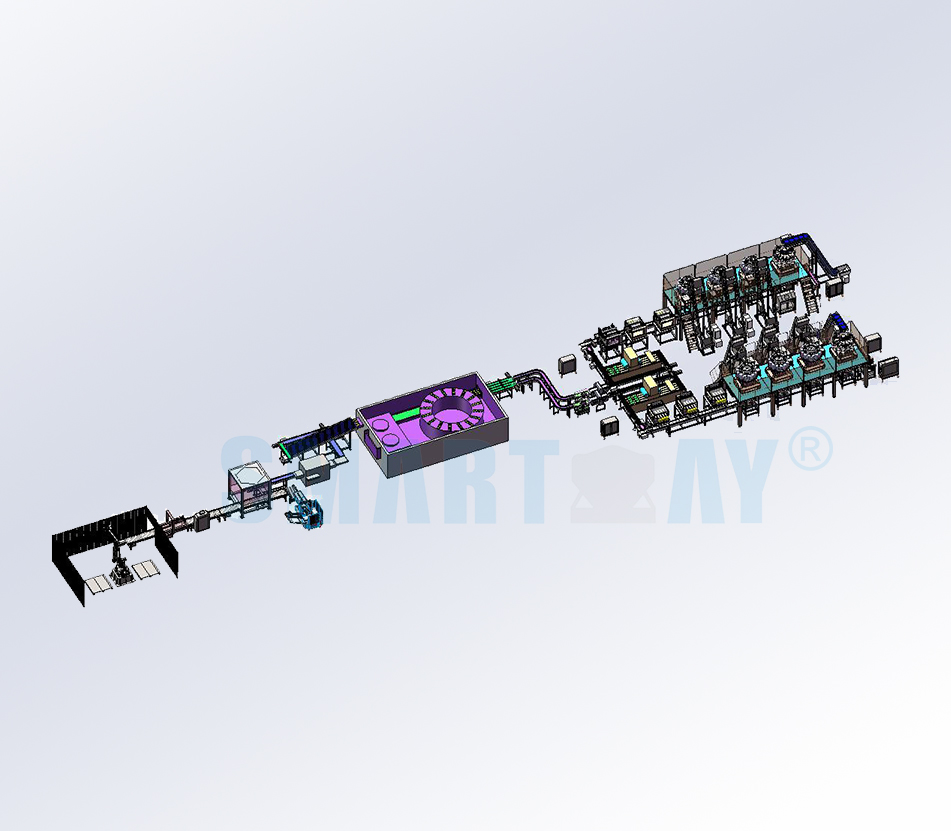

These systems are focused on the first level of packaging that directly contains the product. Examples include systems that fill and seal pouches, bags, or containers. Smart Weigh's solutions ensure precise dosing and secure sealing, crucial for maintaining product integrity, especially in industries like food, pharmaceuticals, and cosmetics.

After primary packaging, products often require secondary packaging, which typically involves grouping primary packages into bundles, cartons, or cases for easier handling and distribution. Smart Weigh offers secondary packaging solutions that automate tasks such as case packing, bundling, and palletizing, ensuring that products are efficiently organized for transport while maintaining order accuracy and minimizing damage during shipping.

These systems are designed to work seamlessly together, providing a fully integrated solution that streamlines the entire packaging process from start to finish.

Automation packaging systems are composed of various interconnected components that work together to ensure seamless and efficient packaging operations. These components are typically divided into two main categories: primary packaging systems and secondary packaging systems.

Primary packaging systems are responsible for the initial stage of packaging, where the product is first enclosed in its immediate container. This is the packaging that directly touches the product and is essential for protecting the product, maintaining its quality, and providing crucial information to the consumer.

Weighing Filling Machines: These machines dispense the correct amount of product into containers such as bags, bottles, or pouches. Precision is key, especially for products like food or pharmaceuticals, where consistency is critical.

Packing Machines: After filling, the product needs to be securely sealed to maintain freshness and prevent contamination.

Secondary packaging systems handle the packaging of the primary packages into larger groups or units for easier handling, transportation, and storage. This stage is crucial for both product protection during transit and efficient distribution.

Case Packers: These machines take multiple primary packages and arrange them into cases or boxes. This grouping facilitates easier handling and shipping while providing an additional layer of protection.

Palletizing Systems: At the end of the packaging line, palletizing systems stack cases or bundles onto pallets. This automation ensures that products are prepared for transport in a stable and organized manner, ready for distribution.

These components work in harmony to create a fully automated packaging process that enhances efficiency, reduces labor costs, and ensures consistent product quality throughout the packaging stages.

When selecting an automated packaging equipments, it's essential to consider several factors:

Product Type: Different products have varying requirements, so choose a system that can handle the specific characteristics of your product.

Production Volume: Consider the scale of your operations. High-volume production may require more robust and faster systems.

Customization Needs: Smart Weigh offers customizable solutions to meet the unique needs of your business, whether it's specialized sealing techniques or integration with existing systems.

Budget: While automation systems can be a significant investment, the long-term cost savings and efficiency gains often justify the expense.

Smart Weigh has successfully implemented automation packaging machine systems across various industries. Here are a few examples:

Automated packaging equipment systems are transforming the way businesses operate, offering unprecedented levels of efficiency, accuracy, and cost savings. Smart Weigh's innovative solutions are designed to meet the diverse needs of modern packaging operations, helping businesses stay competitive in an ever-evolving market.

Whether you're looking to upgrade your existing packaging line or implement a new system from scratch, Smart Weigh has the expertise and technology to deliver the perfect solution. Explore more about Smart Weigh's offerings on their Automation Packaging System page.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved